A simulation test device and test method for the force change law of a filling retaining wall

A technology of change law and simulation test, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the research on the force change law system of filling retaining walls, provide reference for the design of retaining walls that cannot be filled, retaining walls Problems such as incomplete use, etc., to achieve the effect of wide application range, simple structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

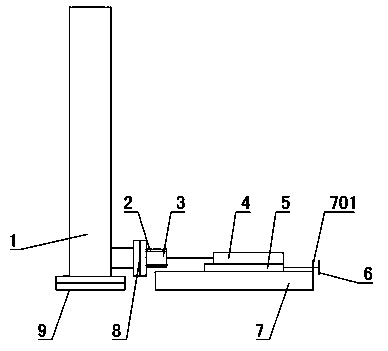

[0035] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0036] A device for simulating and testing the force change law of a filling retaining wall, including a test tube and a measuring device, the test tube is vertically arranged, the side of the test tube is provided with an opening and is closed by an elastic film 8, the measuring device is connected with the elastic film 8, and detects The force that the elastic film 8 is subjected to. The measuring device can measure the force on the elastic membrane 8, so as to measure the pressure of the mortar in the test tube on the elastic membrane 8, and then simulate the change law of the force on the filling retaining wall, and obtain the force of the retaining wall under different filling conditions. It can provide a reference for the design of the filling retaining wall. The test device has a simple structure and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com