Fin heat exchanger cleaning water detection tank

A finned heat exchanger and water detection technology, applied in the testing of instruments, machines/structural components, and by detecting the appearance of fluid at the leak point, etc., can solve the problem of oil-water mixture polluting the environment, difficult to identify water bubbles, and leak detection efficiency. Low problems, to achieve the effect of convenient sewage and water injection, reduce the number of water changes, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

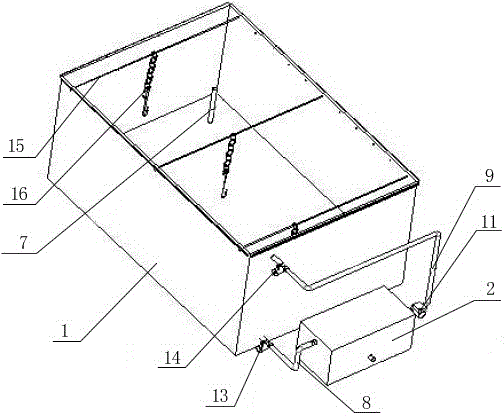

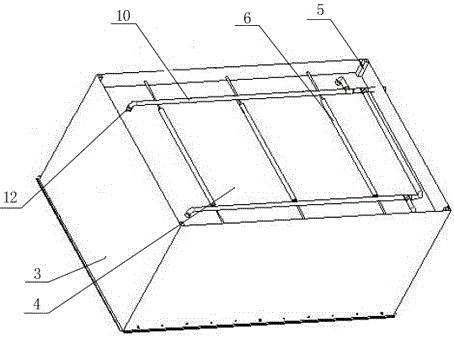

[0012] Such as Figure 1-2 As shown, a finned heat exchanger cleaning water inspection tank of the present invention includes a tank body 1, the outside of the tank body 1 is connected with an oil-water separator 2 through a pipeline, and the tank body 1 includes four side plates 3 and is arranged on the side plate The base plate 4 at the lower end of the side plate 3 is welded with support columns 5 at the four top corners of the inner bottom of the side plate 3. The oil removal water diversion pipe 7 is vertically arranged; the pipeline includes a drain pipe 8 connected to the oil-water separator 2 and a circulation pipe 9, and the drain pipe 8 extends to the bottom of the bottom plate 4, and connects to the bottom of the oil removal water diversion pipe 7 through the branch pipe 10 connected thereto. One end of the circulation pipe 9 is connected to the oil removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com