Composite material-modified electrode used for measuring tyrosine concentration and application thereof

A technology for modifying electrodes and composite materials, which is applied in the field of composite materials modifying electrodes, can solve the problems of cumbersome steps and high detection costs of spectral or chromatographic methods, and achieve the effects of sensitive and efficient measurement, improved tyrosine response current signal, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

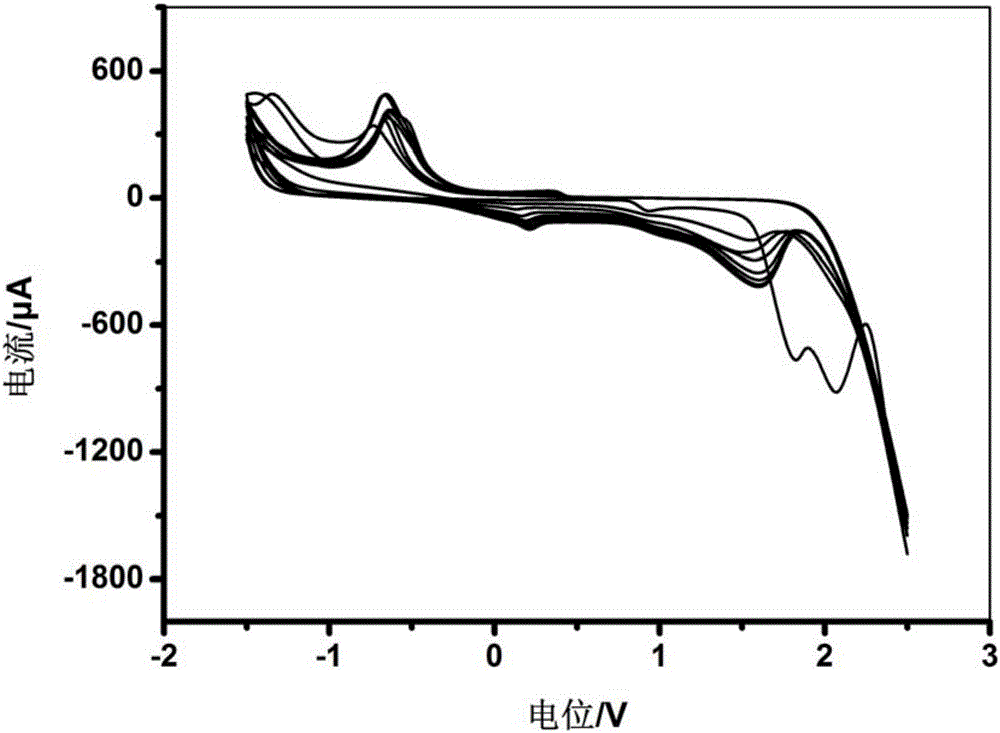

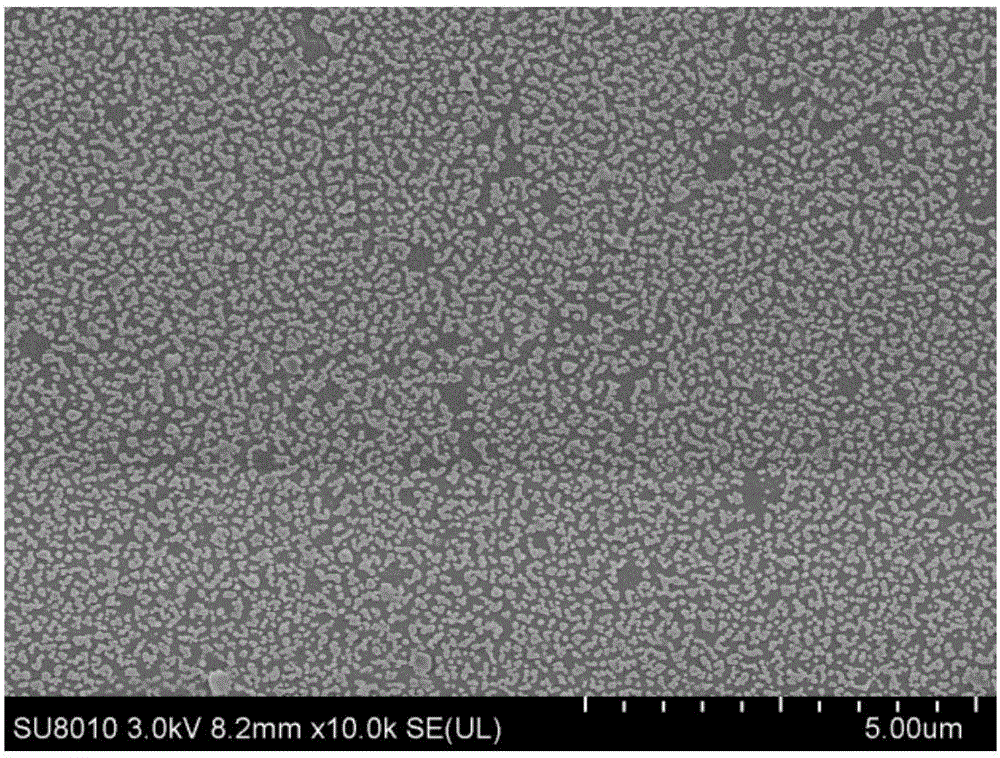

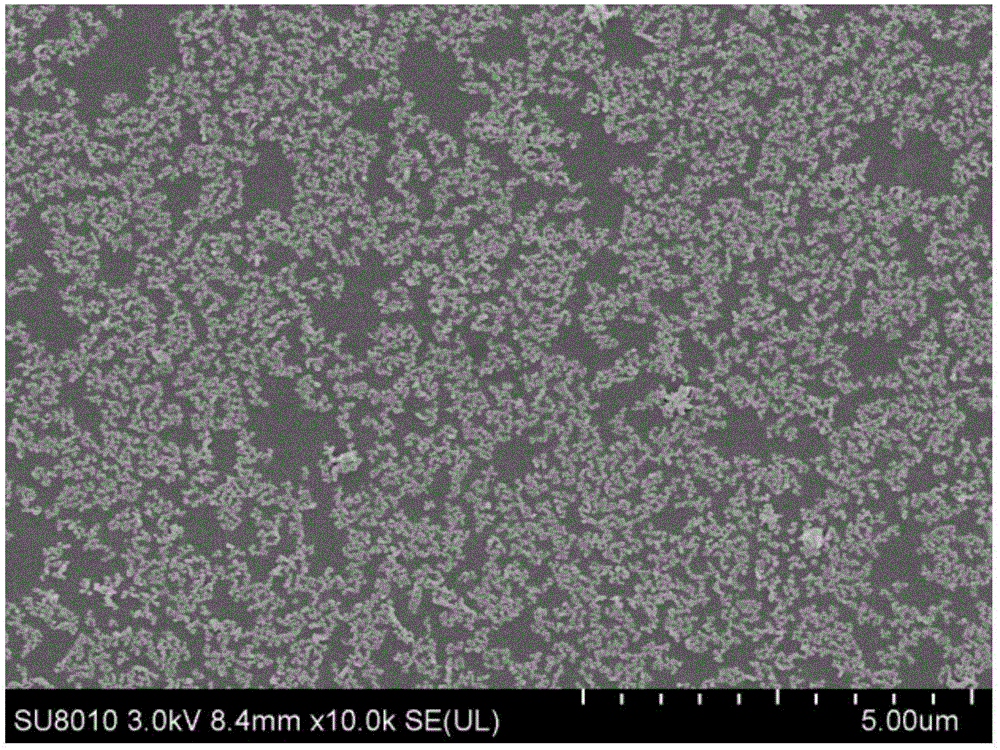

[0022] Preparation of a poly(p-aminobenzenesulfonic acid / gold nanocomposite modified electrode (PABSA / Au / GCE) for the determination of tyrosine concentration comprises the following steps:

[0023] (1) Glassy carbon electrode pretreatment: use α-Al with a particle size of 300nm and 50nm in sequence on the suede 2 o 3 Grind the glassy carbon electrode to the mirror surface with the paste polishing liquid, the mass volume ratio (mg / ml) of polishing powder and deionized water in the paste polishing liquid is 1:1-3, and then apply absolute ethanol and deionized water in sequence The electrode was ultrasonically washed for 1 min, and then the cleaned glassy carbon electrode was placed in a 0.5mol / L dilute sulfuric acid solution, and the cyclic voltammetry activation was performed at a sweep rate of 100mV / s in the potential range of -0.5 to 1.2V until the response was stable. Finally, rinse the glassy carbon electrode with deionized water and dry it for later use.

[0024] (2) Bef...

Embodiment 2

[0036] Preparation of a poly(p-aminobenzenesulfonic acid / gold nanocomposite modified electrode) (PABSA / Au / GCE) for tyrosine determination comprises the following steps:

[0037] (1) Glassy carbon electrode pretreatment: use α-Al with a particle size of 300nm and 50nm in sequence on the suede 2 o 3 Polish the glassy carbon electrode to the mirror surface with paste polishing liquid, then apply absolute ethanol and deionized water to ultrasonically wash the electrode for 90s, and then place the cleaned glassy carbon electrode in 0.6mol / L dilute sulfuric acid solution, in- The 0.6-1.3V potential range was activated by cyclic voltammetry at a scan rate of 120mV / s until the response was stable. Finally, the glassy carbon electrode was rinsed with deionized water and dried in the air for later use.

[0038] (2) The pretreated glassy carbon electrode was placed in 1.5mmol / L chloroauric acid (containing 0.05mol / L potassium nitrate) solution, and the constant potential deposition was ...

Embodiment 3

[0042] Preparation of a poly(p-aminobenzenesulfonic acid / gold nanocomposite modified electrode) (PABSA / Au / GCE) for tyrosine determination, comprising the following steps:

[0043] (1) Glassy carbon electrode pretreatment: use α-Al with a particle size of 300nm and 50nm in sequence on the suede 2 o 3 Polish the glassy carbon electrode to the mirror surface with the paste polishing solution, then use absolute ethanol and deionized water to ultrasonically wash the electrode for 2 minutes, and then place the cleaned glassy carbon electrode in 0.8mol / L dilute sulfuric acid solution, in- The 0.6-1.5V potential range was activated by cyclic voltammetry at a scan rate of 140mV / s until the response was stable. Finally, the glassy carbon electrode was rinsed with deionized water and dried in the air for later use.

[0044] (2) The pretreated glassy carbon electrode was placed in 2mmol / L chloroauric acid (containing 0.15mol / L potassium nitrate) solution, and the constant potential depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com