3D printing model detail area partition filling method based on shape features

A technology of 3D printing and shape features, applied in image data processing, instruments, etc., can solve the problems of low printing model strength, high consumption of consumables, long printing time, etc., to save printing consumables, low filling rate, and improve printing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

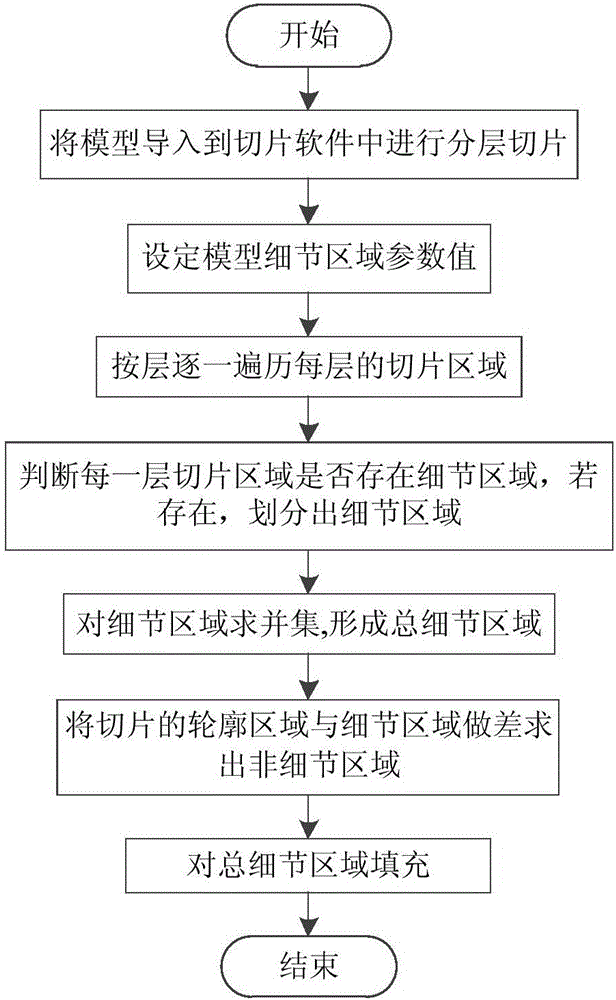

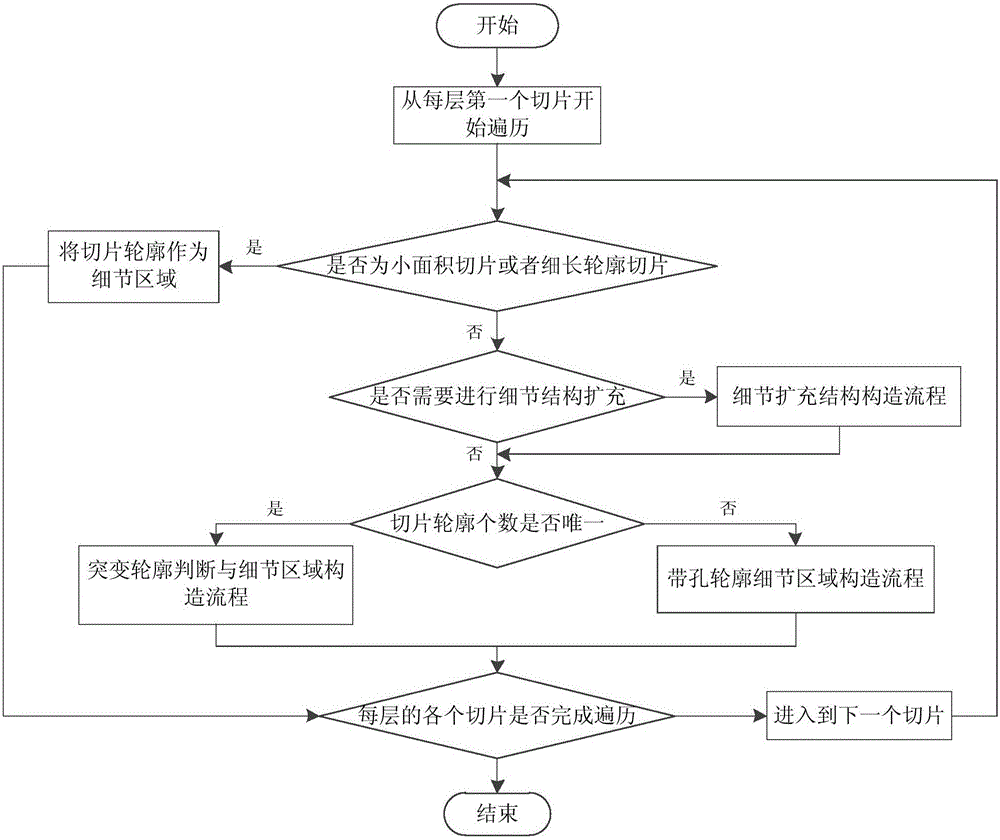

[0039] Such as figure 1 As shown, the present invention provides a 3D printing model detail region filling method based on shape features, which specifically includes the following steps:

[0040] Step 1: Import the model into the slicing software CuraEngine for layered slicing. The model file is a .stl file. Import the model file into the slicing engine. The model is layered and sliced through the slicing engine to generate slice area data for each layer. .

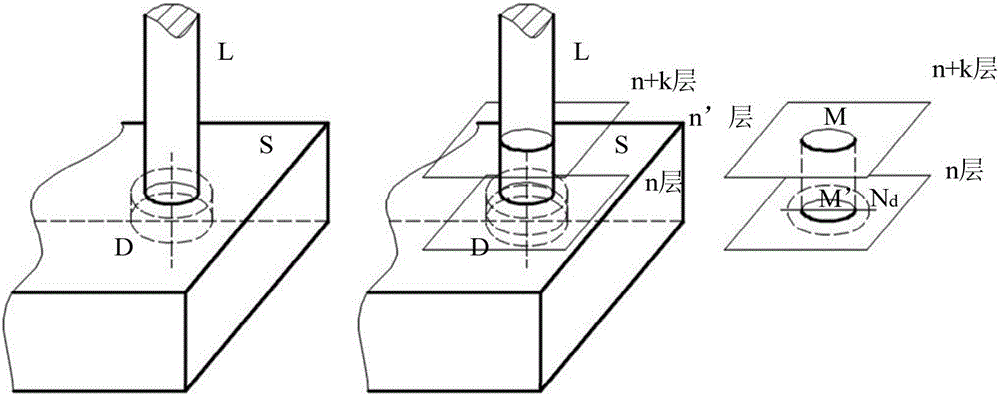

[0041] Step 2: Set the parameter value of the model detail area. The model detail area parameters include detail area threshold, detail length threshold, detail expansion area layer number and detail area filling rate. The detail area threshold and detail length threshold parameters are respectively the detail area threshold. The judging condition is that the number of layers of the detail ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com