Method for estimating rotor position of three-stage brushless AC synchronous motor

A technology of AC synchronous motor and rotor position, which is applied in the direction of synchronous generator control, control generator, motor generator control, etc. It can solve problems such as fault failure, zero position error, and decreased accuracy of position sensor, so as to reduce weight, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

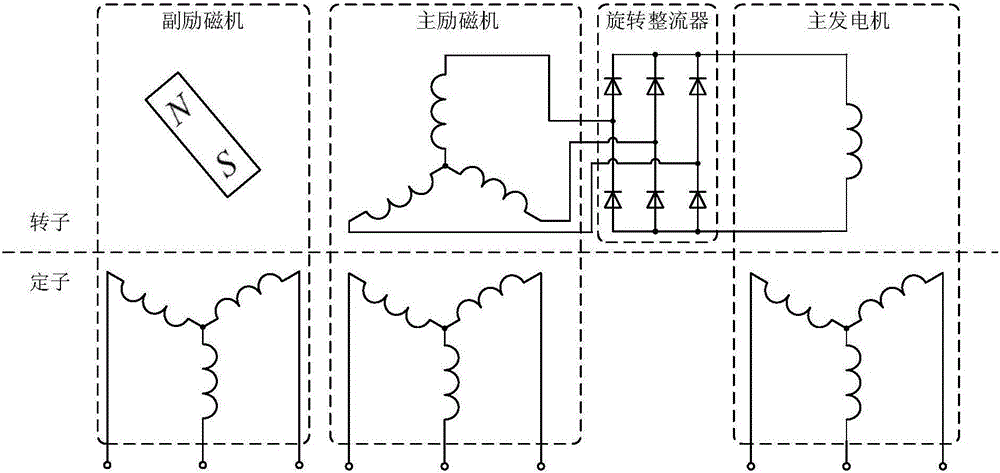

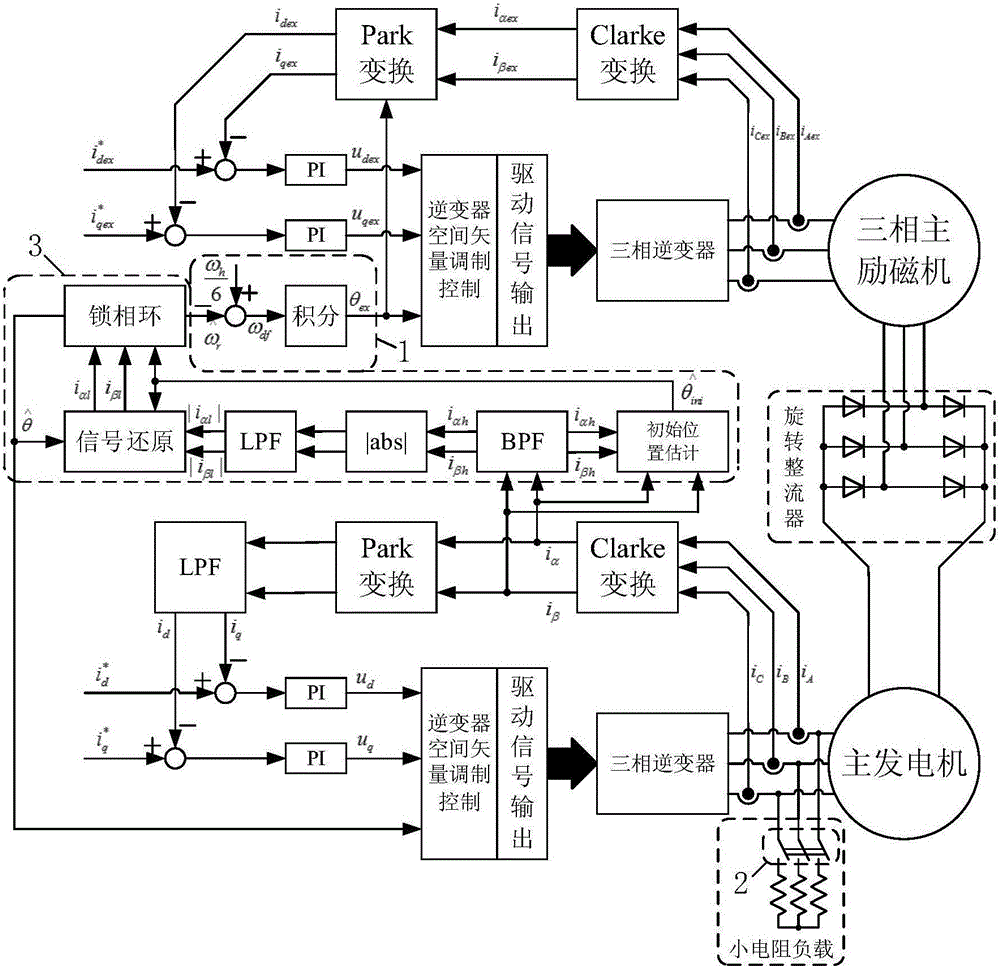

[0039] figure 1 Shown is a schematic structural diagram of a three-stage brushless AC synchronous motor applicable to the present invention, wherein the main generator is connected to the main exciter through a rotating rectifier, and the main exciter is a three-phase excitation winding, where the three-phase excitation winding is connected to Input a certain frequency of three-phase alternating current, the three-phase alternating current is used as the three-phase excitation current of the main exciter, set the slip frequency between the excitation magnetic potential and the motor rotor as one-sixth of the frequency of the high-frequency signal to be injected, and the rotor side The induced alternating current generates direct current with high-frequency harmonic components after passing through the rotating rectifier, which provides exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com