Environmentally friendly inorganic coating agent composition, and preparation method therefor

A coating agent and composition technology, applied in the field of environment-friendly inorganic coating agent composition and its preparation, can solve the problems of inability to meet solution stability, application limitations, low curability, etc., and achieve compatibility and dispersion. Good, improved compatibility, low adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

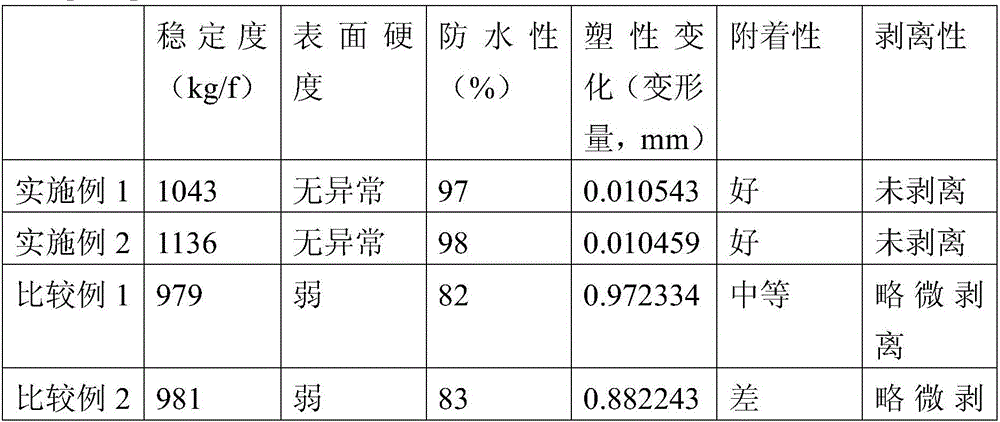

Examples

preparation example Construction

[0038] According to another aspect of the present invention, there is provided a method for preparing an inorganic coating agent composition, comprising the following steps: the step of forming a modified silane silicate composition, based on 100 parts by weight of silicate, adding to the The silicate is added with 0.1 to 2 parts by weight of silane, diluted at a temperature range of 95 to 110 ° C, and stirred at a speed of 200 to 400 rpm for 1 to 2 hours; the silane compound formation step is based on 100 parts by weight of silane, mixing silane and After 0.01 to 3 parts by weight of a catalyst formed of hydrochloric acid, sulfuric acid or a mixture thereof, and 70 to 120 parts by weight of water, stirring at 200 to 400 rpm for 1 to 4 hours at a temperature range of 80 to 90 ° C, thereby forming a hydrolyzed silane compound ; In the temperature range of 65 to 110 ° C, based on 100 parts by weight of the modified silane silicate composition prepared according to the step of for...

Embodiment 1

[0095] First, 100 g of alkali silicate and 1 g of plastic trimethoxysilane were mixed, and stirred at a speed of 300 rpm for 1.5 hours at a temperature of 97° C. or higher to form a modified silane silicate composition.

[0096] Next, 100 g of epoxysilane, 1 g of hydrochloric acid, and 100 g of water were mixed, added to epoxysilane, and stirred at about 300 rpm for 3 hours at a temperature of 85° C. to form a hydrolyzed silane compound.

[0097] Next, while maintaining a temperature of 70°C, 100 g of the modified silane silicate compound, 20 g of a hydrolyzed silane compound, 150 g of a water-dispersible polyurethane dispersant, 15 g of acrylic emulsion resin, and 100 g of water were mixed to prepare an inorganic coating agent composition. .

Embodiment 2

[0099] First, 100 g of alkali silicate and 1 g of plastic trimethoxysilane were mixed, and stirred at a speed of 300 rpm for 1.5 hours at a temperature of 97° C. or higher to form a modified silane silicate composite.

[0100] Next, after mixing 1 g of hydrochloric acid and 100 g of water to 100 g of epoxy silane, it added and mixed with epoxy silane, and stirred at 300 rpm for 3 hours in the temperature range of 85 degreeC, and formed the hydrolysis silane compound.

[0101] Next, maintain a temperature of 70° C., mix 100 g of the modified silane silicate compound, 20 g of the hydrolyzed silane compound, 150 g of water-dispersible polyurethane dispersant, 15 g of acrylic emulsion resin, 20 g of surfactant composed of amine salt, and 100 g of water. Thus, an inorganic coating agent composition was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com