Flue gas waste heat recovery device with vertical low-resistance heat pipes

A technology of a flue gas waste heat and recovery device, which is applied in the field of flue gas waste heat recovery, can solve the problems of blockage of the gas outlet, low exchange efficiency, environmental heat pollution, etc., and achieves improved heat exchange efficiency, increased heat transfer effect, and low heat exchange coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

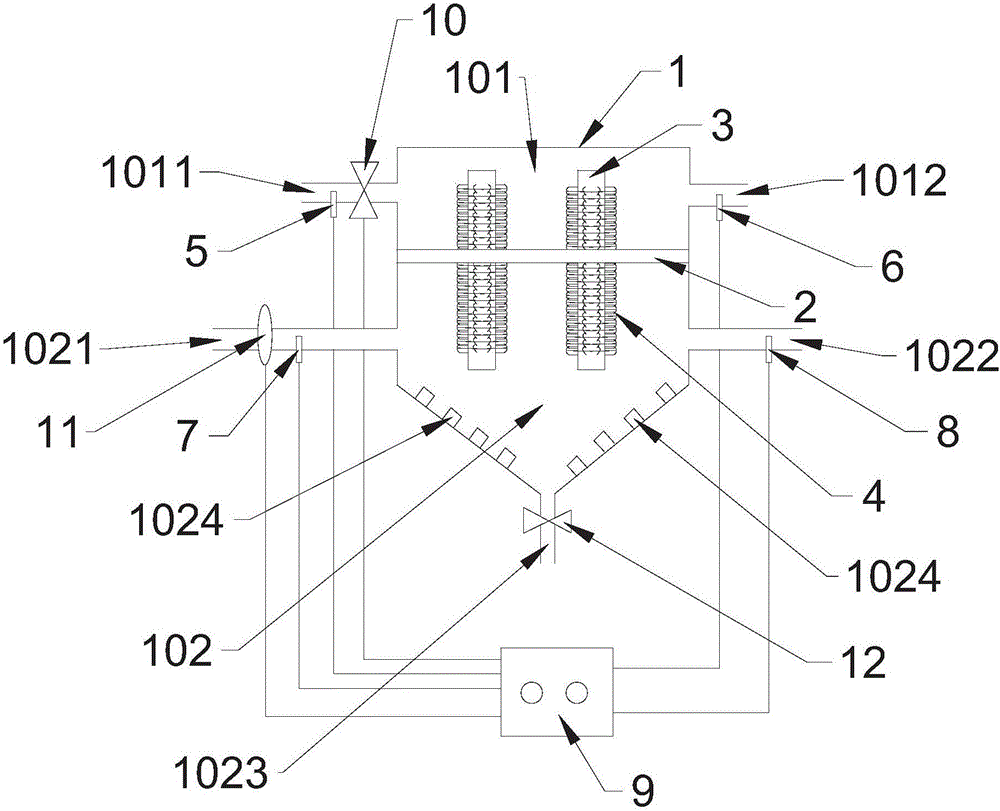

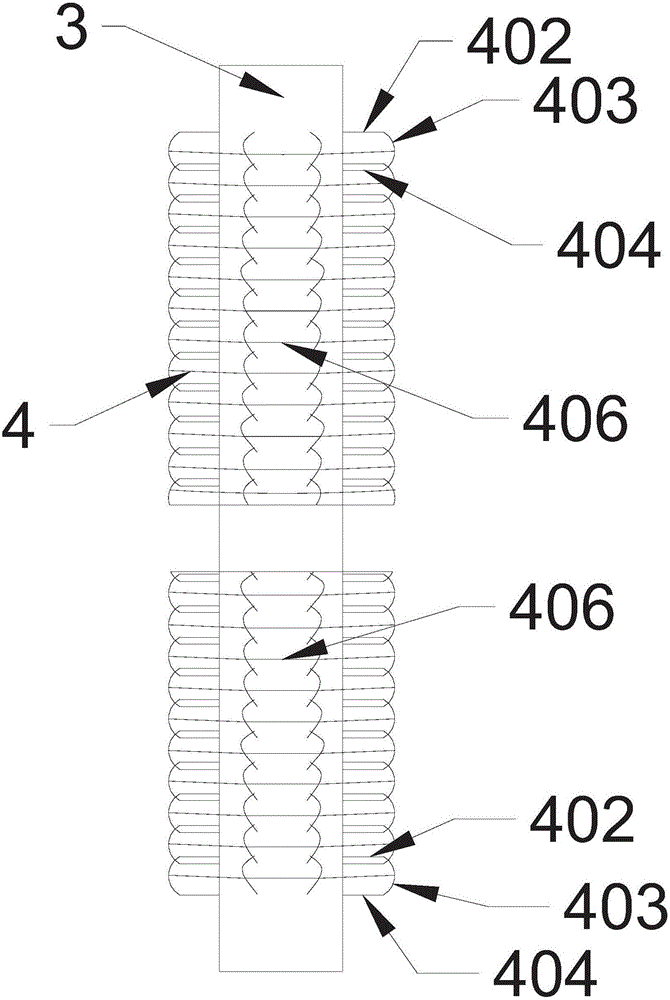

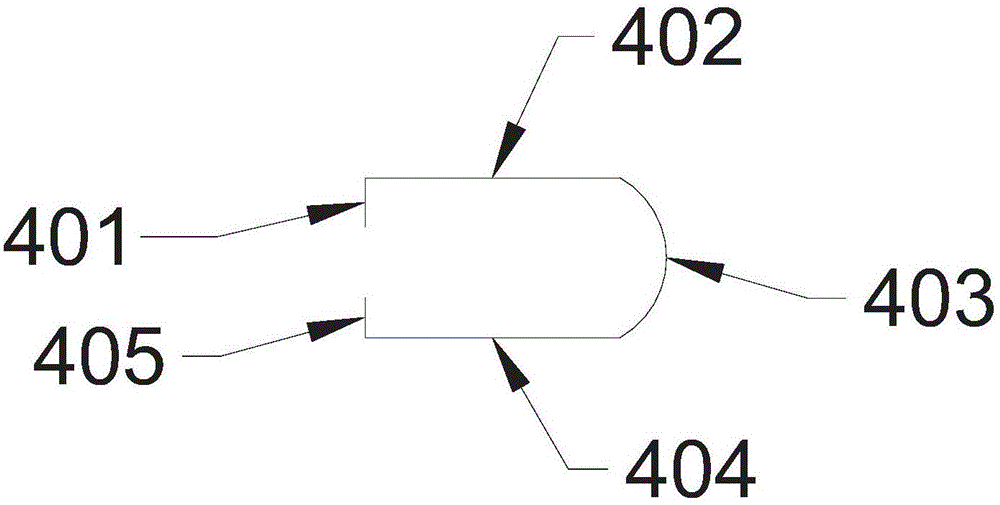

[0020] Figure 1 to Figure 4 Schematically shows a flue gas waste heat recovery device with vertical low-resistance heat pipes according to an embodiment of the present invention. As shown in the figure, the flue gas waste heat recovery device with vertical low-resistance heat pipes includes a shell 1, a heat shield 2 and several heat pipes 3, and the material of the heat shield 2 can be selected by technicians according to actual needs; the shell 1. The upper shell 101 and the lower shell 102 are separated by the heat insulation plate 2. The heat exchange medium inlet 1011 and the heat exchange medium outlet 1012 are respectively provided on both sides of the upper shell 101. The heat exchange medium is used to store the flue gas from The heat recovered in the heat exchange medium can be water or other fluids. The two sides of the lower housing 102 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com