Device and method for determination of trace moisture content of sulfur hexafluoride gas

A technology of sulfur hexafluoride gas and trace moisture, applied in the direction of electrochemical variables of materials, etc., can solve the problems of hindering the wide application of detection methods, inconvenient on-site testing, and large detection results, and achieves the goal of being suitable for popularization and use, simple in structure, and low in consumption. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for measuring trace moisture content of sulfur hexafluoride gas, including the following steps:

[0039] A. Inhale a certain amount of sulfur hexafluoride gas at a constant speed;

[0040] B. Inhaled sulfur hexafluoride gas electrolyzed in the electrolysis cell of the Coulomb meter;

[0041] C. Collect relevant data, and measure the moisture content in sulfur hexafluoride gas according to Karl Fischer coulometric method.

Embodiment 2

[0043] This embodiment is refined on the basis of the above embodiment, that is, in step C, the specific method for calculating the moisture content in the sulfur hexafluoride gas is:

[0044] The relationship between the moisture in the gas and the amount of electrolysis is: = ;

[0045] which is: ;

[0046] Then the moisture content in the gas is: ;

[0047] Among them, W is the moisture in the gas, the unit is μg;

[0048] Q is the electrolysis power, the unit is mC;

[0049] C is the moisture content in the gas, the unit is μl / L;

[0050] V is the volume of the measured gas under standard atmospheric pressure, in L.

[0051] According to the relational expression of the moisture content in the gas, it can be known that the moisture content in the gas can be obtained only by collecting the electrolysis power data.

[0052] In step A, the amount of sulfur hexafluoride gas inhaled is 0.5L, and its instantaneous flow rate is controlled to be 400SCCM.

[0053] The electrolysis rate in the...

Embodiment 3

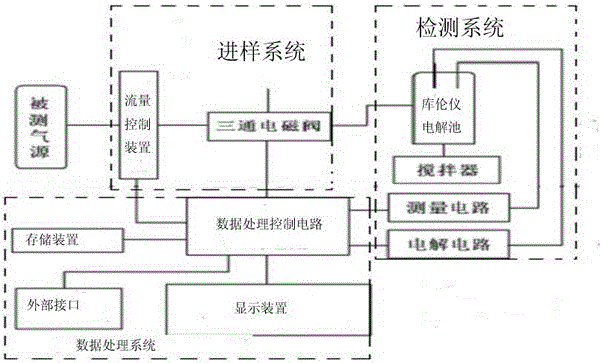

[0057] Such as figure 1 A device for measuring the trace moisture content of sulfur hexafluoride gas is shown, including a sampling system, a detection system and a data processing system connected in sequence;

[0058] The sampling system includes a flow control device for controlling the flow of the incoming sulfur hexafluoride gas;

[0059] The detection system includes a coulomb meter electrolysis cell, an electrolysis circuit connected in the coulomb meter electrolysis cell, and a measurement circuit for measuring electrolysis parameters;

[0060] The data processing system includes a storage device, a display device, and a data processing control circuit that uses the electrolysis parameters of the measurement circuit to obtain the moisture content in the sulfur hexafluoride gas according to the Karl Fischer coulometric method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com