An inclined green walnut peeling machine

A technology of green walnut peeling machine, which is applied in the field of inclined green walnut peeling machine, can solve the problems of low peeling rate, effective cutting, leakage, etc., and achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

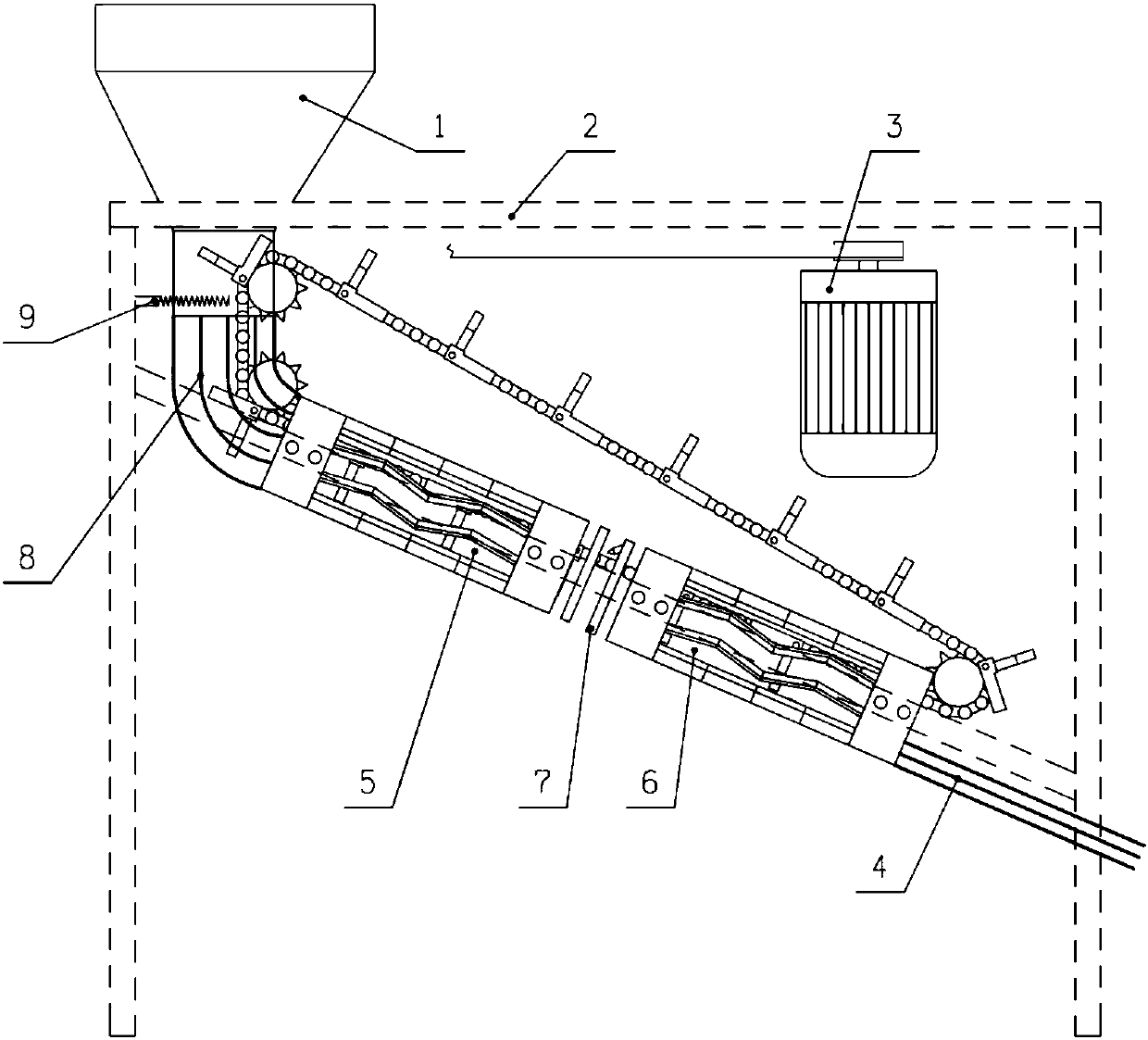

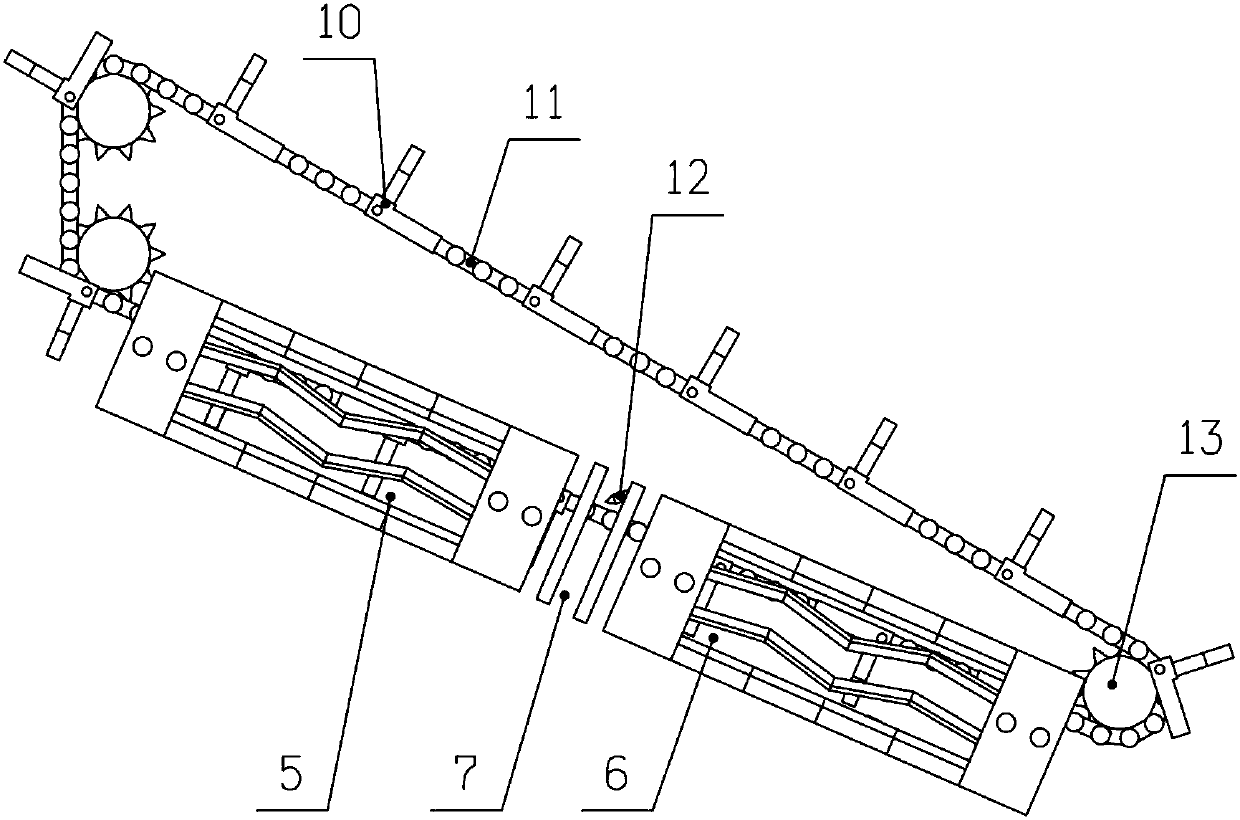

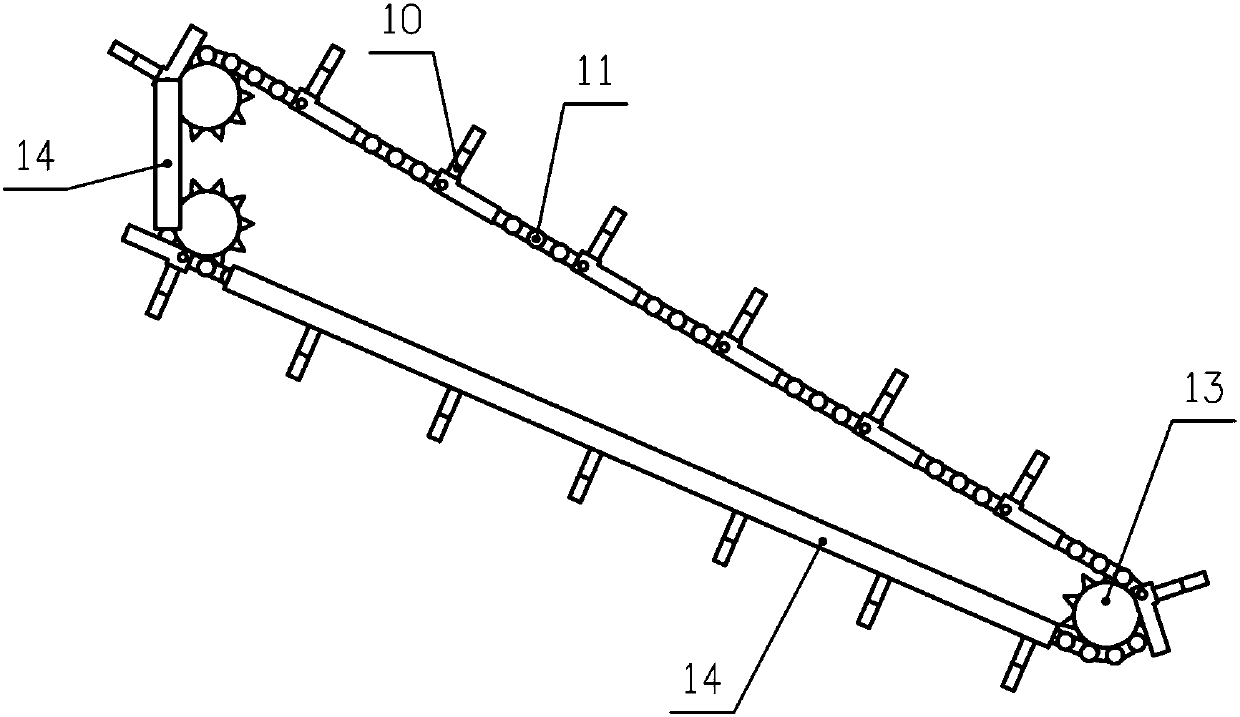

[0032] Such as Figure 1-2As shown, a kind of inclined type green walnut peeling machine of the present invention comprises transmission device 3, conveying device, feed hopper 1, discharge port 20, discharge restriction device 9, cutting device, turning device 7 and discharge Mouth 4. The transmission device 3 includes a motor, a belt, and a reducer, and the conveying device includes a conveying seat 10, a double-row chain 11, a sprocket wheel 13 and a guide bar 14, and the conveying device is fixed by a bearing on the sprocket wheel 13 and a bearing seat In the frame 2, the cutting device is composed of a first cutting section 5 and a second cutting section 6 with the same structure.

[0033] Such as Figure 4-8 As shown, the cutting section includes a knife seat 15 and a cutting blade 18, and the knife seat 15 is composed of two semicircular tubes, and there is a certain gap between the two semicircular tubes, which are vertical on the arc surface of the semicircular tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com