Workbench of five-axis drilling and planting integrated machine

An all-in-one machine and workbench technology, applied in the direction of brushes, brushes, household appliances, etc., can solve the problems of not meeting the needs of brush body drilling and hair planting, long manufacturing cycle, small stroke, etc., to facilitate modular production and replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

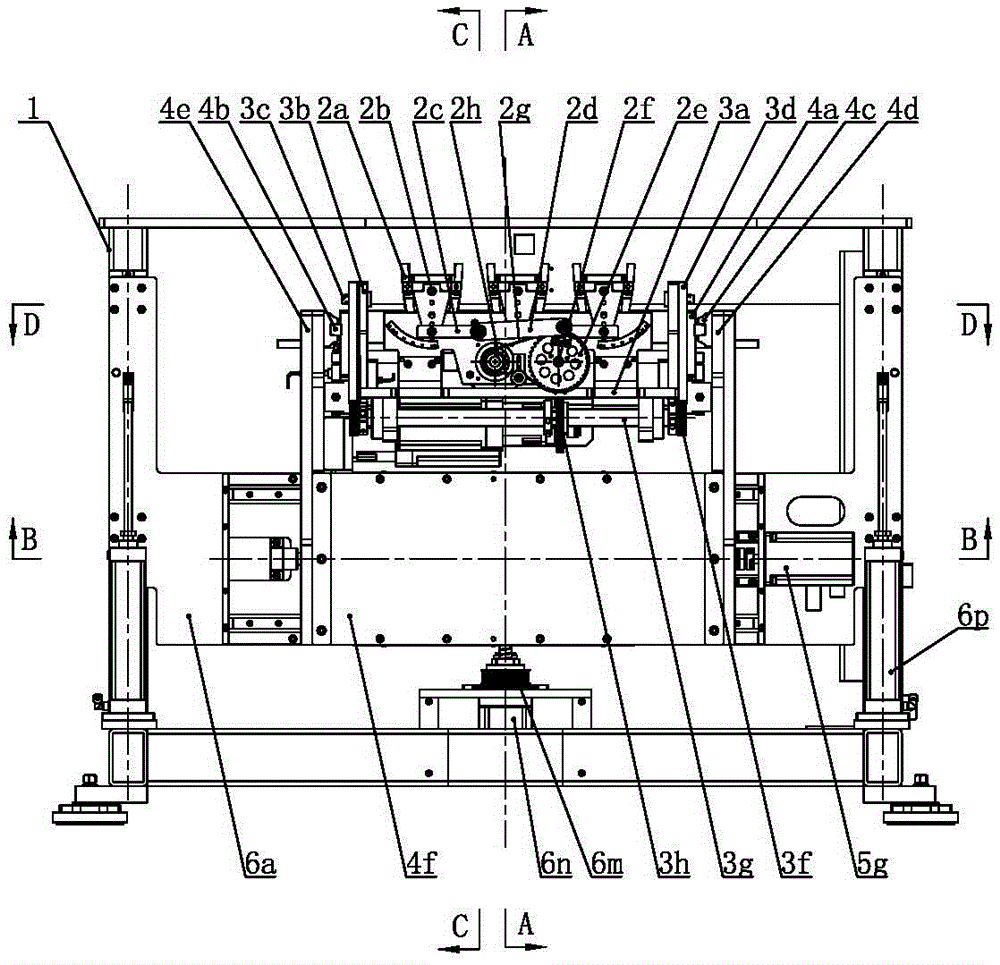

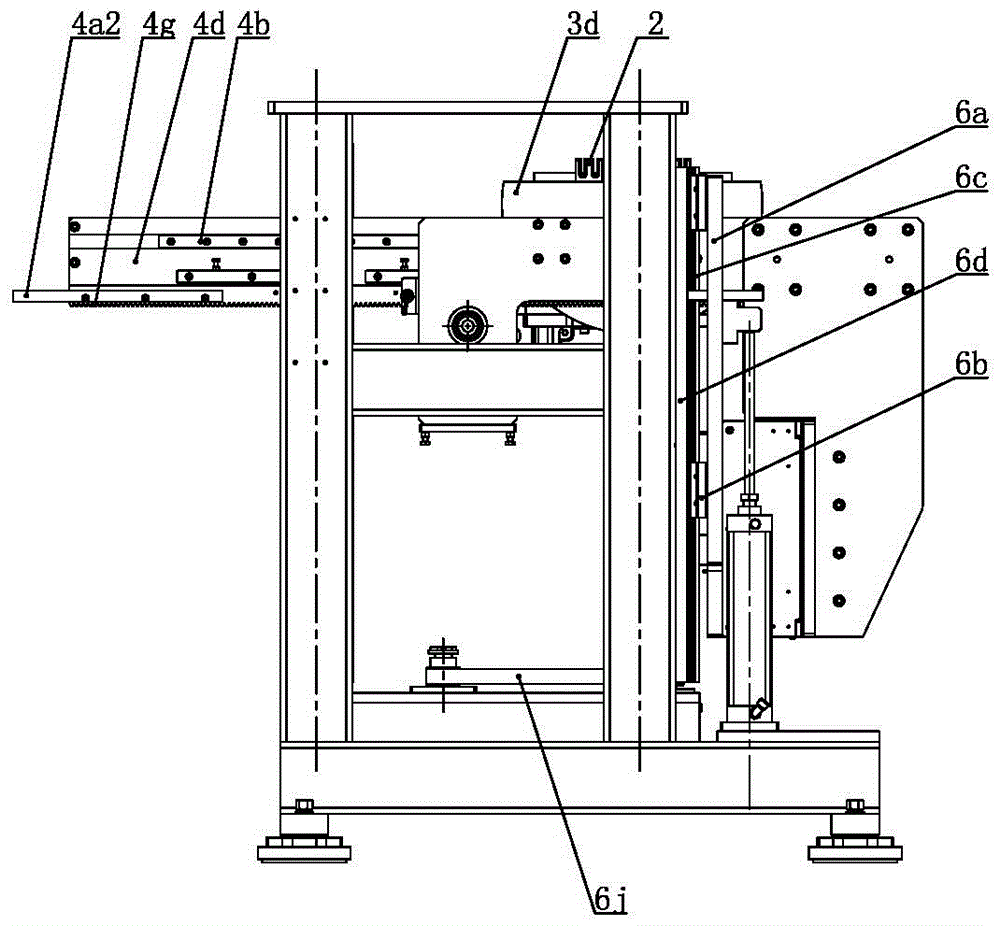

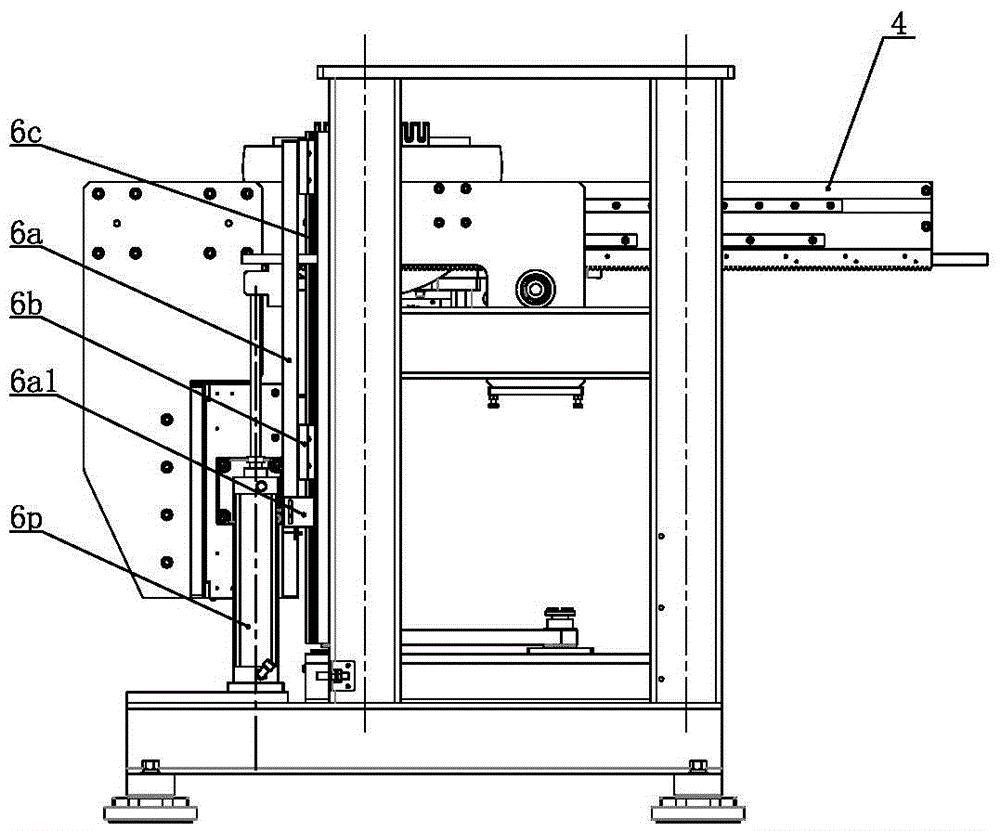

[0030] Such as Figure 1 to Figure 13 As shown, the workbench of the five-axis drilling and planting integrated machine of the present invention includes a frame 1 and a brush body fixture assembly 2, and the brush body fixture assembly 2 includes a B-axis swing mechanism and a plurality of brush body fixtures that can hold the brush body 2a, each brush body fixture 2a can swing around the B-axis driven by the B-axis swing mechanism, the brush body fixture assembly 2 is fixedly installed on the A-axis swing mechanism 3, and the A-axis swing mechanism 3 is installed on the Y-axis that can move back and forth On the translation mechanism 4, the Y-axis translation mechanism 4 is installed on the X-axis translation mechanism 5 that can move left and right, the X-axis translation mechanism 5 is installed on the Z-axis lifting mechanism 6 that can move up and down, and the A rotation axis of the A-axis swing mechanism 3 3c is parallel to the X-axis, and the B rotation axis of the B-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com