Method for cleaning desulfurizing tower filler

A desulfurization tower, water cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, separation methods, etc., can solve the problems of increased resistance of desulfurization towers, affecting normal gas transmission, and reducing the specific surface area of packing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

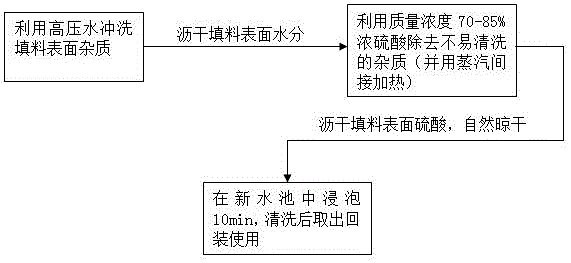

[0017] A method for cleaning desulfurization packing, comprising the steps of high-pressure water washing (1), concentrated sulfuric acid reaction (2) and water washing (3), the specific method is as follows:

[0018] High-pressure water flushing (1): Take out the filler blocked by impurities such as sulfur from the desulfurization tower, and first flush it with high-pressure water for 10 minutes. Effectively wash off the clogging impurities from the surface of the packing. Excessive water pressure will damage the celadon packing and destroy the integrity of the packing. The pressure of the water flow is generally 40-80bar to wash away the sulfur attached to the surface of the packing.

[0019] Concentrated sulfuric acid reaction (2): Drain the water on the filler, and then put the filler one by one into a corrosion-resistant cleaning tank with a mass fraction of 70% concentrated sulfuric acid to react, and use steam to indirect heat to 80°C, steam indirect heating can make Th...

Embodiment 2

[0023] A method for cleaning desulfurization packing, comprising the steps of high-pressure water washing (1), concentrated sulfuric acid reaction (2) and water washing (3), the specific method is as follows:

[0024] High-pressure water flushing (1): Take out the packing blocked by impurities such as sulfur from the desulfurization tower, and first flush it with high-pressure water for 5 minutes. Effectively wash off the clogging impurities from the surface of the packing. Excessive water pressure will damage the celadon packing and destroy the integrity of the packing. The pressure of the water flow is generally 40-80bar to wash away the sulfur attached to the surface of the packing.

[0025] Concentrated sulfuric acid reaction (2): Drain the water on the filler, and then put the filler one by one into a corrosion-resistant cleaning tank with a mass fraction of 85% concentrated sulfuric acid to react, and use steam to indirect heat to 40°C, steam indirect heating can make Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap