Device for cleaning replaced insulators

A technology for insulators and cleaning devices, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reduced insulation performance of porcelain parts and insulators, increased surface leakage current, and moisture absorption of dirt on the insulating surface, etc. problems, to achieve the effect of environmentally friendly flushing water consumption, reduce usage, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

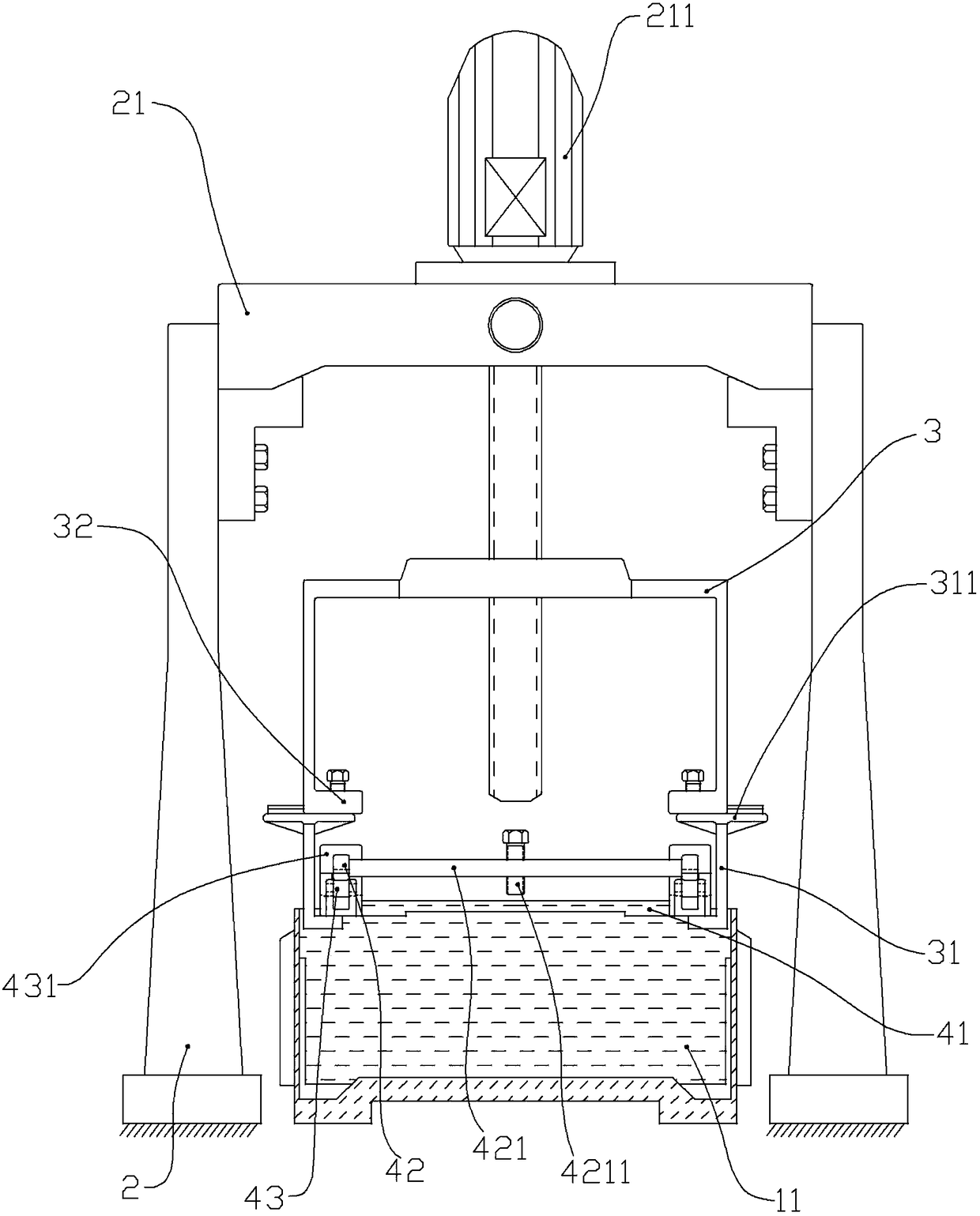

[0036] Such as Figure 1 to Figure 6 A device for cleaning replaced insulators shown includes a slot group 1, a gantry frame 2, a U-shaped seat 3, a clamping group unit 4 and a control unit.

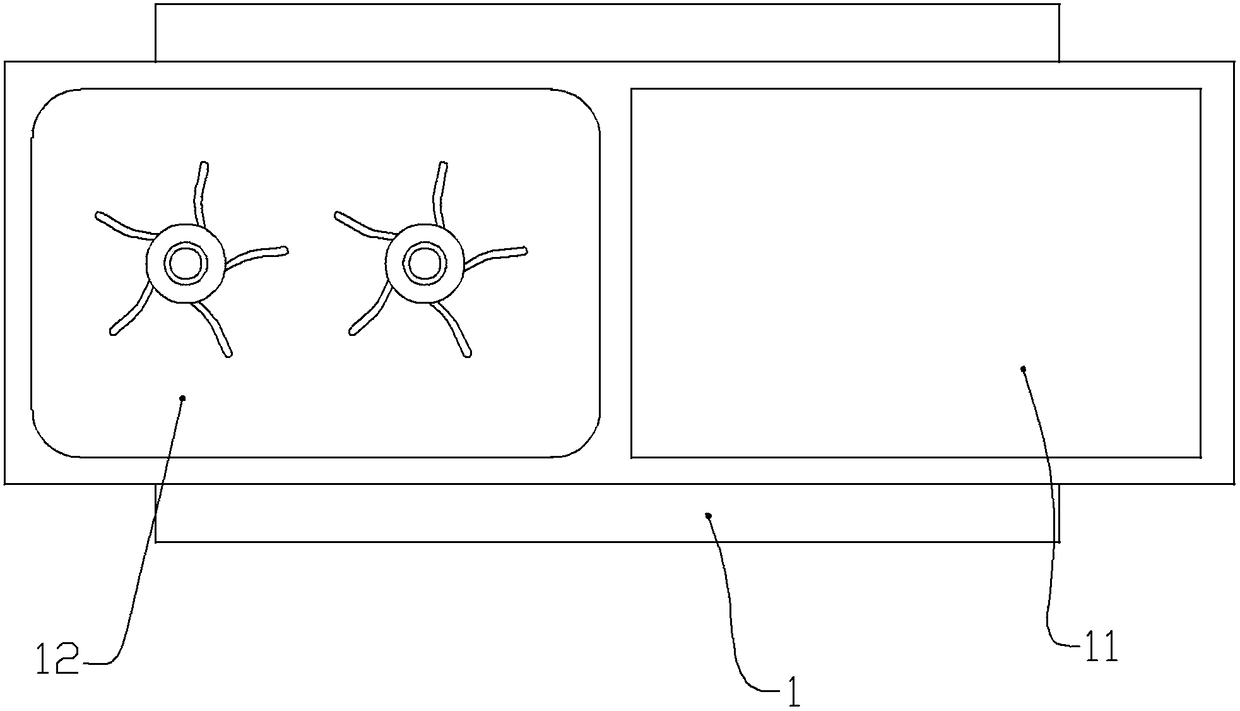

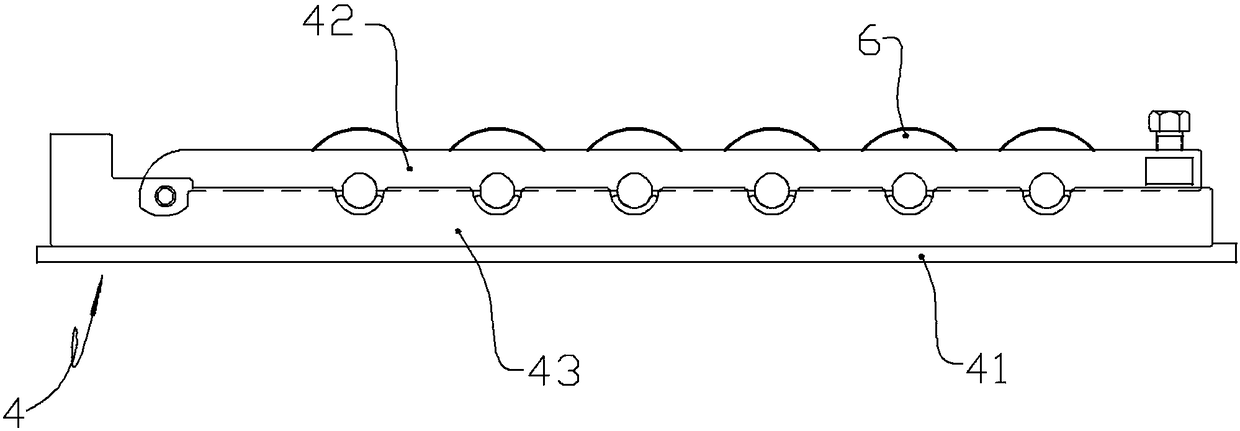

[0037] Such as figure 1 , figure 2 As shown, the tank group 1 is placed under the gantry 2, and includes a cleaning tank 11 and a flushing tank 12 arranged in front and back, and an ultrasonic cleaning device is arranged in the cleaning tank 11 . The upper end of the gantry 2 is provided with a slider transmission mechanism that can slide horizontally in the front and rear direction, and a lifting drive motor 211 is installed on the slider 21 upper end of the slider transmission mechanism. bar. The cross arm of the U-shaped seat 3 cooperates with the lead screw to form a lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com