All-purpose vertical spinning machine with horizontally-arranged spinning rollers

A horizontal spinning machine technology, applied in the field of spinning machines, can solve problems such as uneven cooling and heating of brake hubs, explosions, cracks, cracks, etc., to achieve changing shape and thickness, improving tensile strength, and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

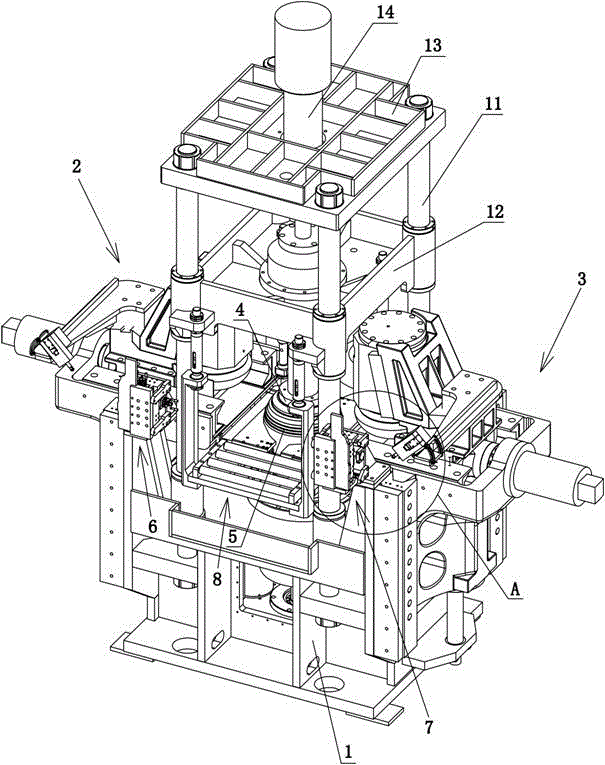

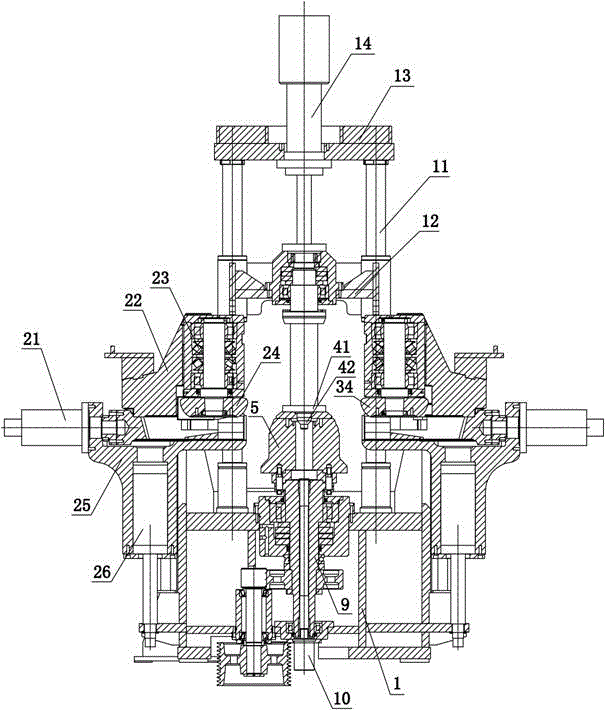

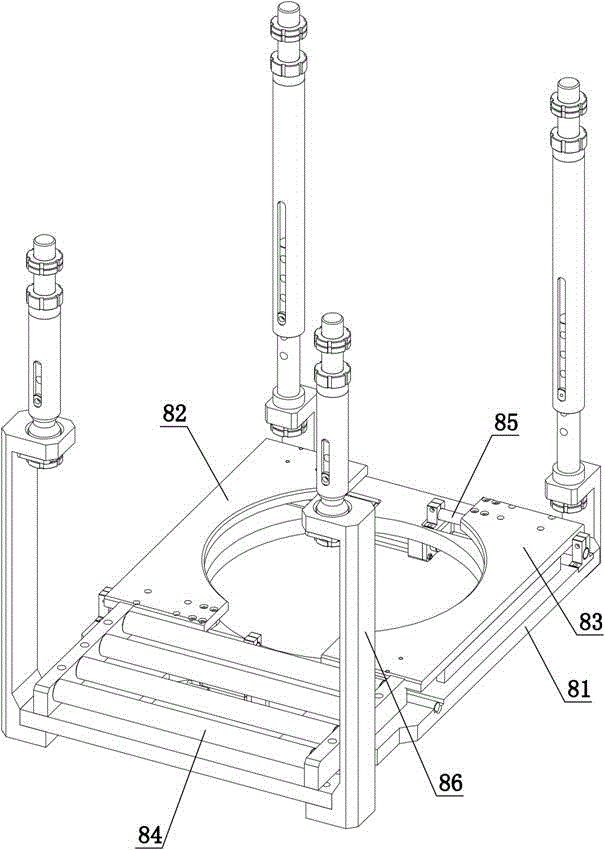

[0015] refer to figure 1 with figure 2 . Rotary flat universal vertical spinning machine, including base 1, coarse spinning mechanism 2, fine spinning mechanism 3, positioning and pressing seat 4, spinning mandrel 5, rough spinning profiling mechanism 6, fine spinning imitation Shape mechanism 7 and material holding mechanism 8. The rough rotation mechanism 2 and the fine rotation mechanism 3 are arranged on the left and right parts of the base 1 so that they can move left and right and can be lifted up and down respectively, and the coarse rotation mechanism 2 and the fine rotation mechanism 3 are arranged horizontally. The spinning mandrel 5 is arranged in the middle of the base 1 , and the positioning and pressing seat 4 is arranged above the spinning mandrel 5 . The top surface of the base 1 is provided with four columns 11 arranged in a square shape, the four columns 11 are provided with movable beams 12, and the top surfaces of the four columns 11 are fixedly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com