Correlation photoelectric device of steel pipe length measurement system device

A technology of photoelectric and photoelectric devices, applied in shearing devices, accessories of shearing machines, measuring/indicating equipment, etc., can solve the problems of affecting safe production, inaccurate measurement, time-consuming, etc., to reduce labor intensity, improve Cutting speed, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

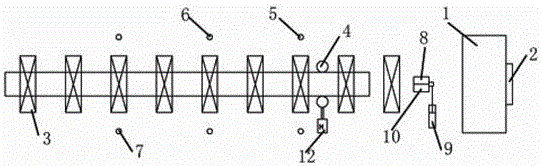

[0009] Combine below figure 1 Specific description embodiment:

[0010] Steel pipe length measuring system device, the steel pipe length measuring device system includes a pipe cutting machine 1, a cutter head 2 is provided on one side of the pipe cutting machine 1, and a center roller table 3 is provided on the other side of the pipe cutting machine 1, and the The center roller table 3 is provided with pinch rollers 4 that can pinch the steel pipe; the two sides of the center roller table 3 are provided with 3 groups of photoelectric devices; the first group of photoelectric devices 5 and the knife The distance between the heads 2 is 5000mm, the distance between the second group of photoelectric devices 6 and the cutter head 2 is 8000mm, and the distance between the third group of photoelectric devices 7 and the cutter head 2 is 10500mm; A measuring roller 8 is arranged between the pipe cutting machine 1 and the central roller table 3, the measuring roller 8 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com