Hydraulic motor driving steering system based on full hydraulic steering device

A technology of hydraulic motor and steering system, applied in the field of steering system, can solve the problems of difficult layout and difficult realization, and achieve the effect of flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

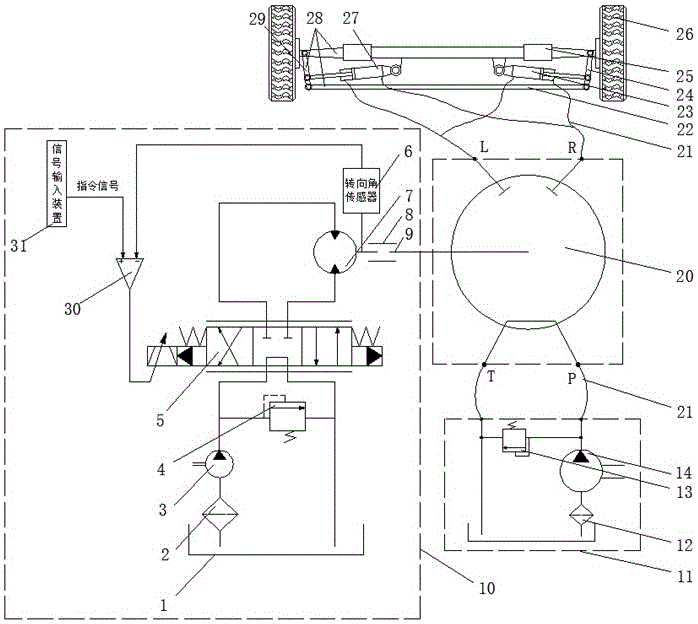

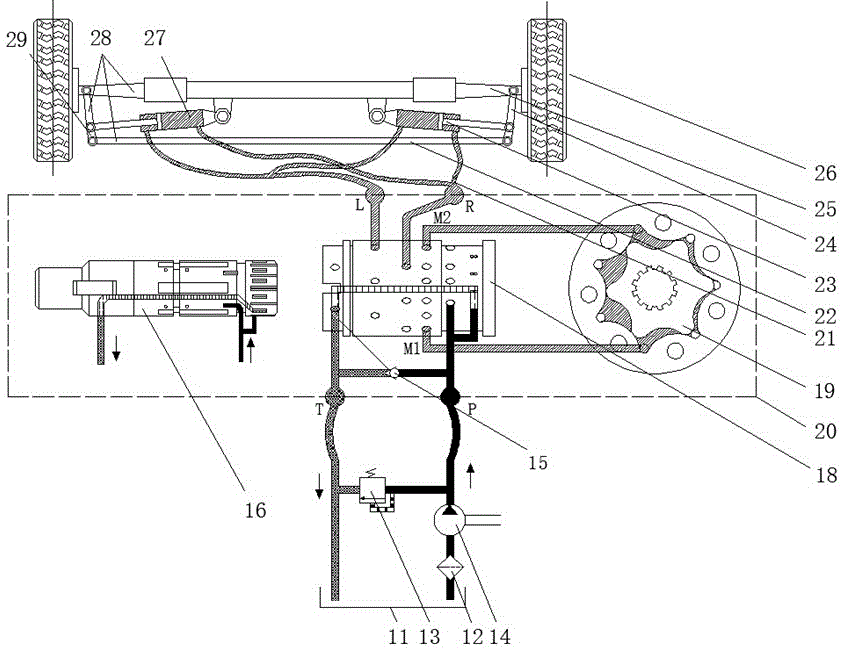

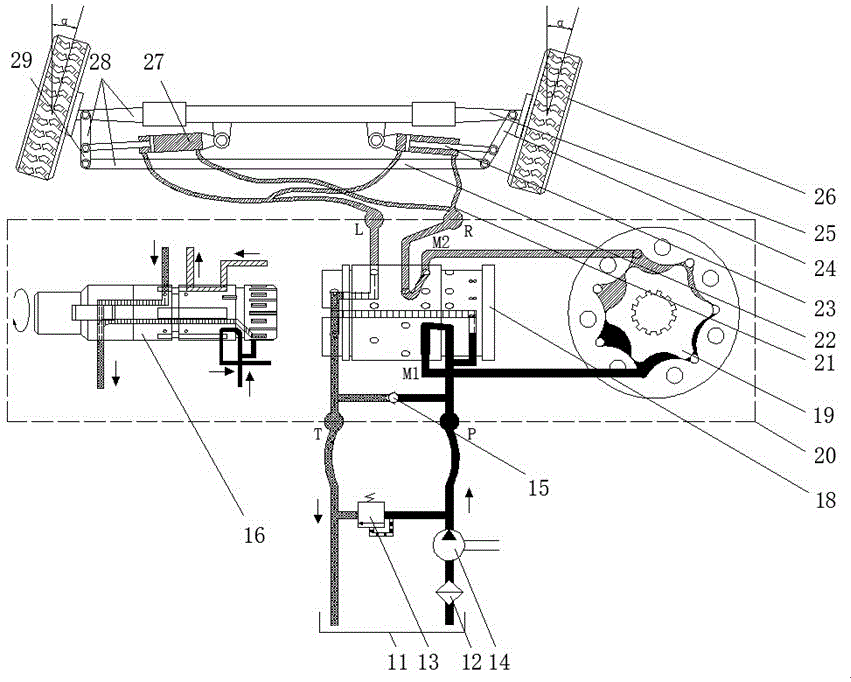

[0034] Example 1: figure 1 A schematic diagram of a hydraulic motor driven full hydraulic steering control system. The signal input device 31 is one of an electric control handle, an electronically controlled analog steering wheel, or a wireless transmission device. The driver forms a steering command signal through the signal input device 31, and the steering angle sensor 6 detects the rotation signal of the hydraulic motor 7. Two kinds of signals After being amplified by the speed controller 30, the control current is output to control the opening and closing of the electro-hydraulic servo valve 5, and the corresponding pressure oil is output to drive the hydraulic motor 7 to turn, forming a closed-loop control of the hydraulic motor speed. The hydraulic motor 7 drives the full hydraulic steering gear 20, the hydraulic pump 14 sucks hydraulic oil from the second oil tank 11, enters the full hydraulic steering gear 20 through the hydraulic hose 21, and then enters the left st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com