Ducted propeller with equal forward and reverse thrust force

An equal thrust, forward and reverse technology, applied in the direction of rotary propellers, ship propulsion, propulsion components, etc., can solve the problems of insufficient key technology, immature theoretical research, and limitations in popularization and application, and achieve high efficiency and improved propulsion. Efficiency, the effect of improving maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

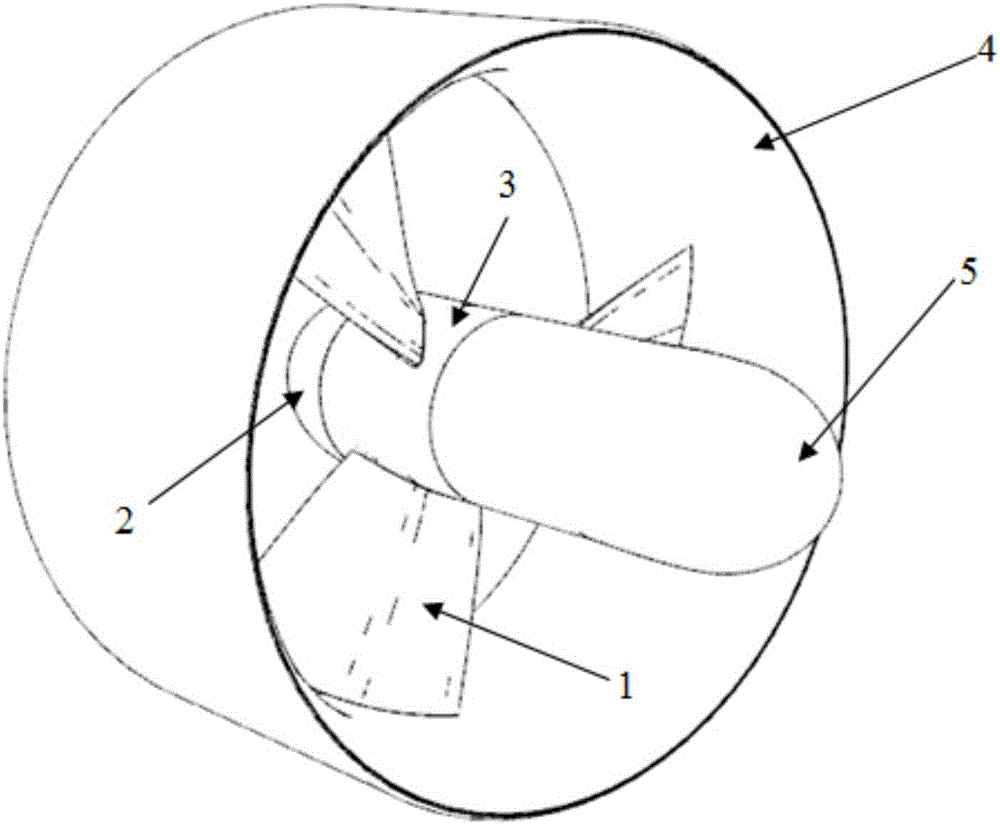

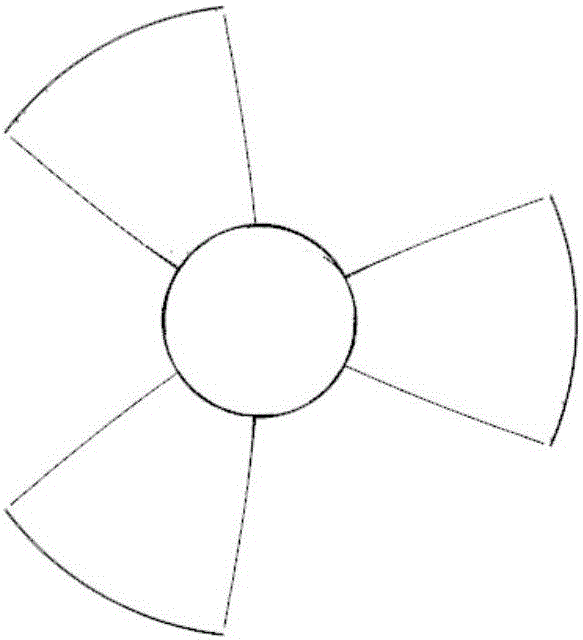

[0019] Combine below Figure 1~7(b) The forward and reverse equal-thrust catheter propeller device of the present invention is introduced in detail. figure 1 The general layout of the propeller is given, mainly including the propeller 1, the shroud 4, the propeller hub 3, the hub cap 2 and the nacelle 5 and so on. Each blade of the propeller 1 is fixed on the propeller hub 3, and the spinner 4 is on the periphery of the propeller.

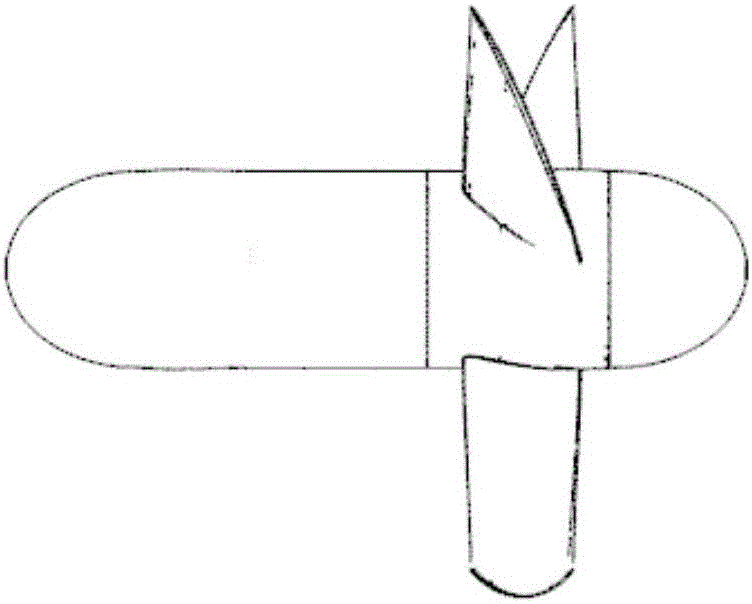

[0020] Fig. 2 has provided the overall view of the propeller, propeller hub, hub cap and nacelle of this propeller, propeller hub 3 hub diameter ratio is 0.3-0.35, and the diameter of propeller hub 3, hub cap 2 and nacelle 3 are identical, hub cap 2 and the shape of the end of the nacelle 5 are the same, and both adopt an elliptical shape, thereby ensuring the same inflow at the front and rear ends. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com