Cigarette case comprising integrated combined self-sealing inner package

An inner packaging and self-sealing technology, applied in cigarette packaging, packaging, transportation and packaging, etc., can solve the problems of increasing packaging process difficulty, defective products, and reducing packaging efficiency, so as to facilitate repeated uncovering and bonding, and folding and forming The process is simple, the use process is safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

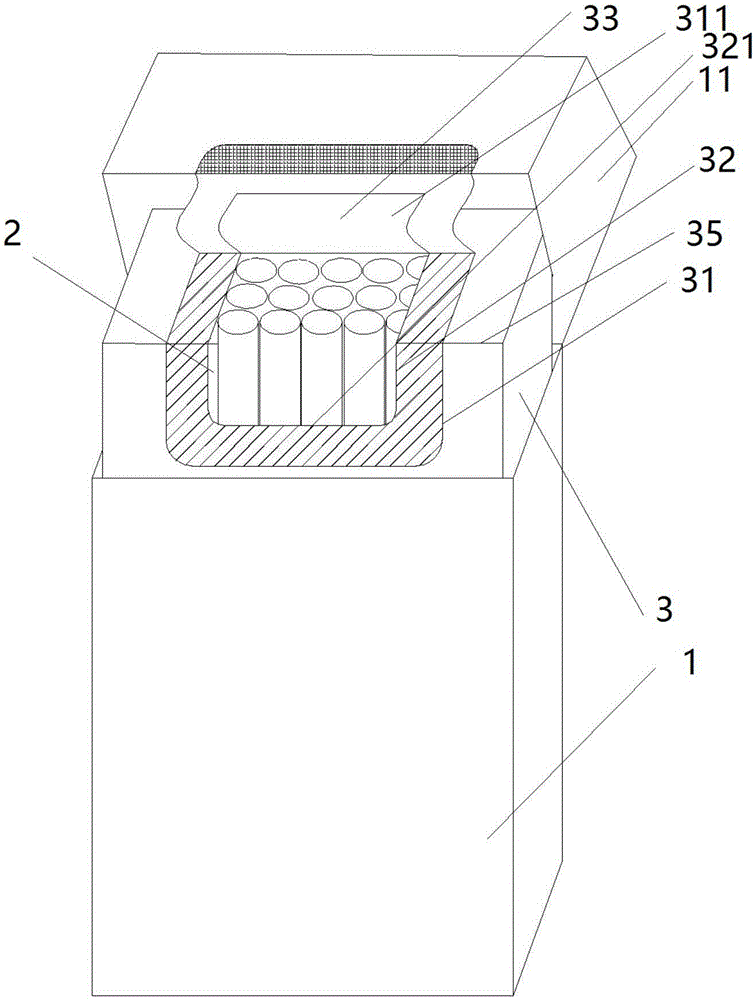

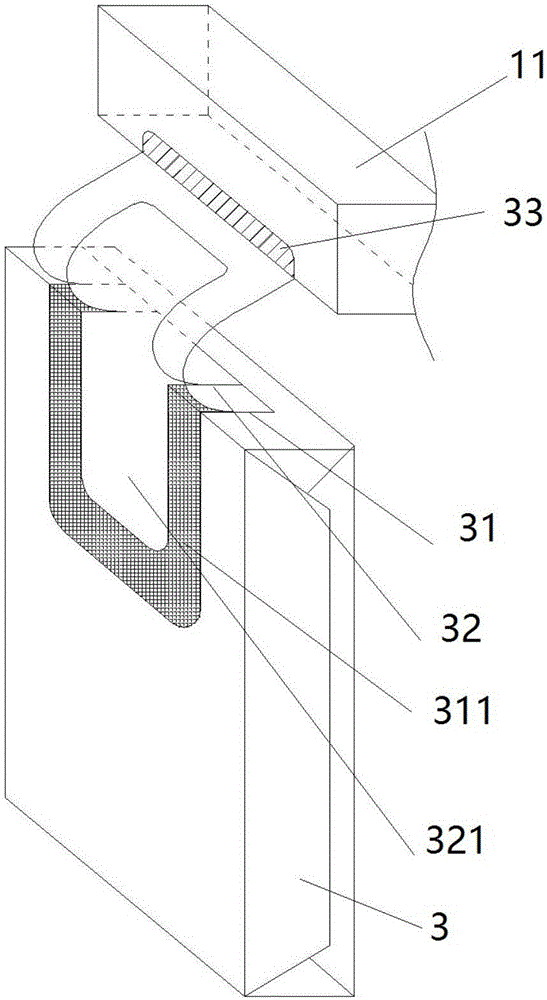

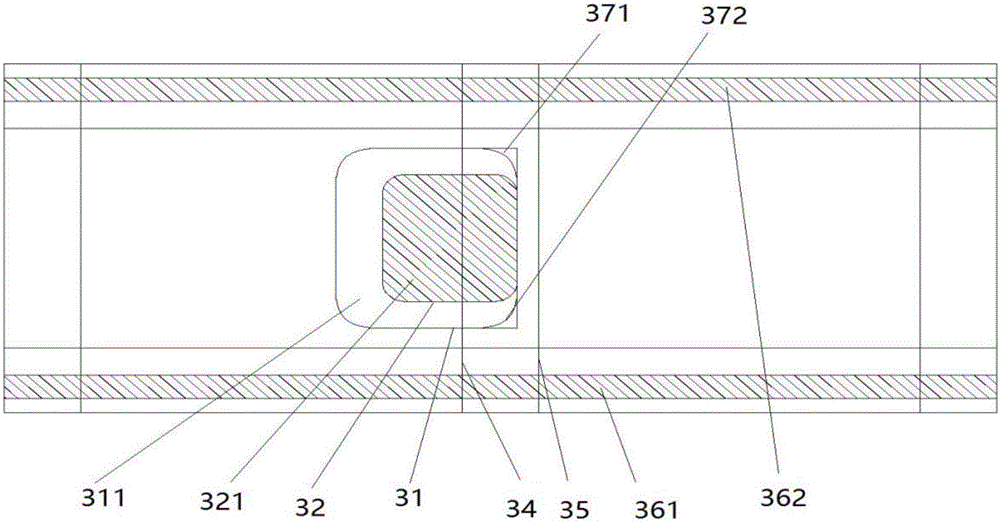

[0024] according to Figure 1-4 As shown in FIG. 1 , it is a schematic diagram of the three-dimensional structure of a cigarette case including an integrated composite self-sealing inner package according to an embodiment of the present invention. Such as figure 1 As shown, the cigarette case includes an outer box 1, an inner frame 2, and an inner packaging 3, and the upper part of the inner frame has an opening 21; the outer box 1 is placed outside the inner packaging 3; the inner packaging 3 is a double-layer composite base The material is folded in one piece. The base material includes an outer layer base material and an inner layer base material; the inner layer base material is in contact with the inner frame 2; the outer layer base material is in contact with the outer box 2; the middle part of the outer layer base material has a semi-penetrating The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com