Dust control method and device of power plant coal transport system

A technology for coal conveying system and dust, applied in the field of dust control of coal conveying system in power plants, can solve the problems of endangering the health of operators, affecting the safe and civilized production of power plants, and lack of dust and dust suppression measures, so as to avoid spontaneous combustion of pulverized coal and reduce Effect of dust inhalation and reduction of pulverized coal accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

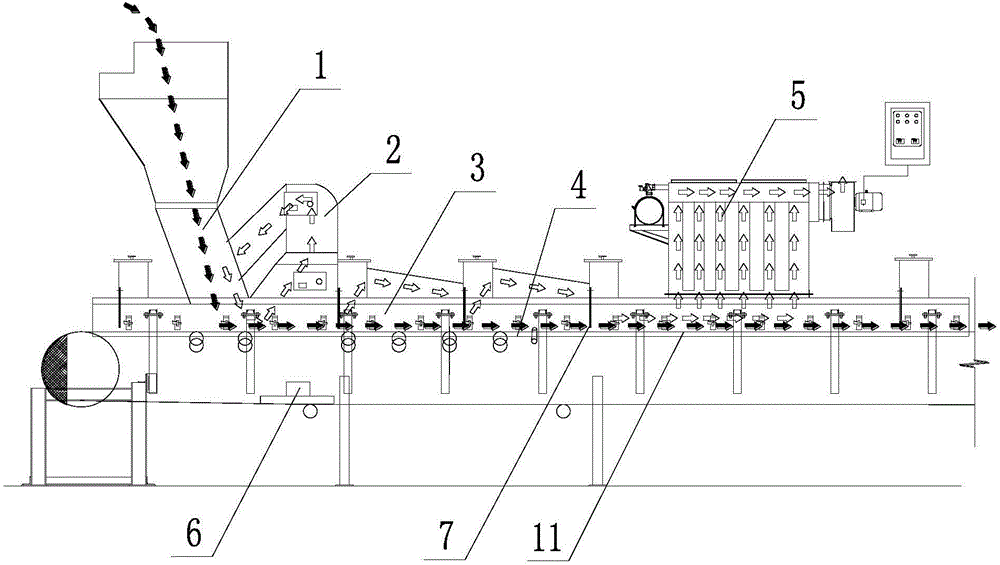

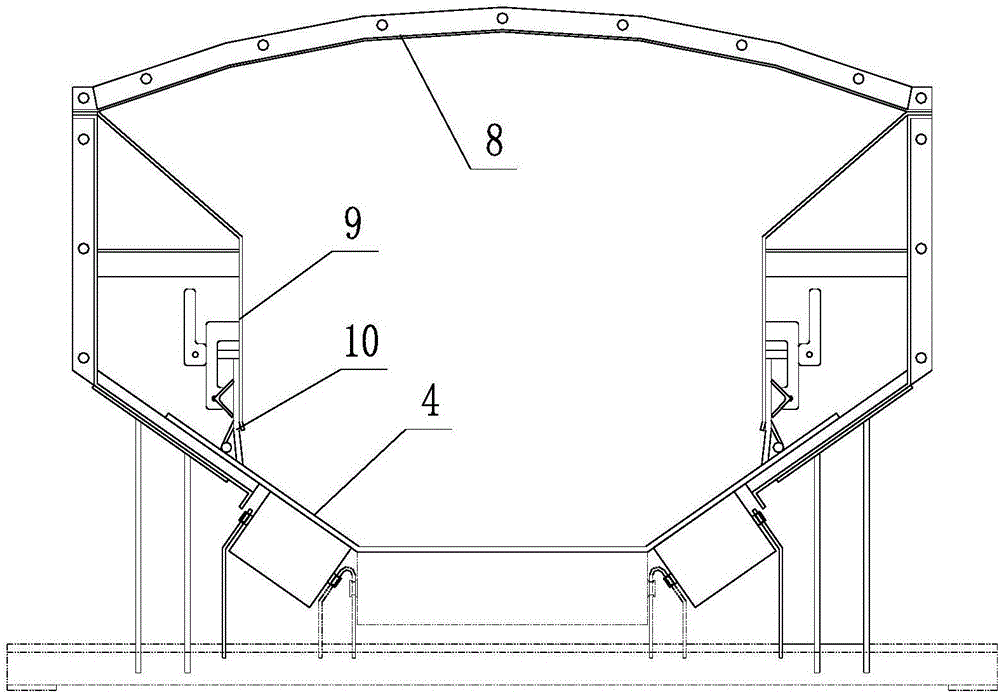

[0023] Example 1 of the dust control method for the coal conveying system of a power plant: a dust control method for the coal conveying system of a power plant, which is used to reduce the concentration of dust generated by the coal conveying system. One end is located in the material guide trough, including the following methods: reduce the positive air pressure in the material guide trough; intermittently spray the non-working surface of the coal conveyor belt outside the material guide trough and the non-sealed parts of the rollers at both ends; the material guide trough adopts Sealed structure. Said reducing the positive airflow pressure in the feed chute comprises the following methods: a micro-power dust collector communicated with the feed trough is arranged at an end downstream of the feeding direction on the feed chute, and the feed trough is carried out by the micro-power dust collector. Inhale, remove dust. An unpowered dust collecting chamber and / or a return pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com