Intelligent light-adjusting energy-saving laminated glass and preparation method thereof

A technology for intelligent dimming and laminated glass, which is applied in chemical instruments and methods, glass/slag layered products, coatings, etc., can solve the problems of low economic benefits and high requirements for production processes, and achieve simple and low-cost preparation methods. , the effect of obvious reflective ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

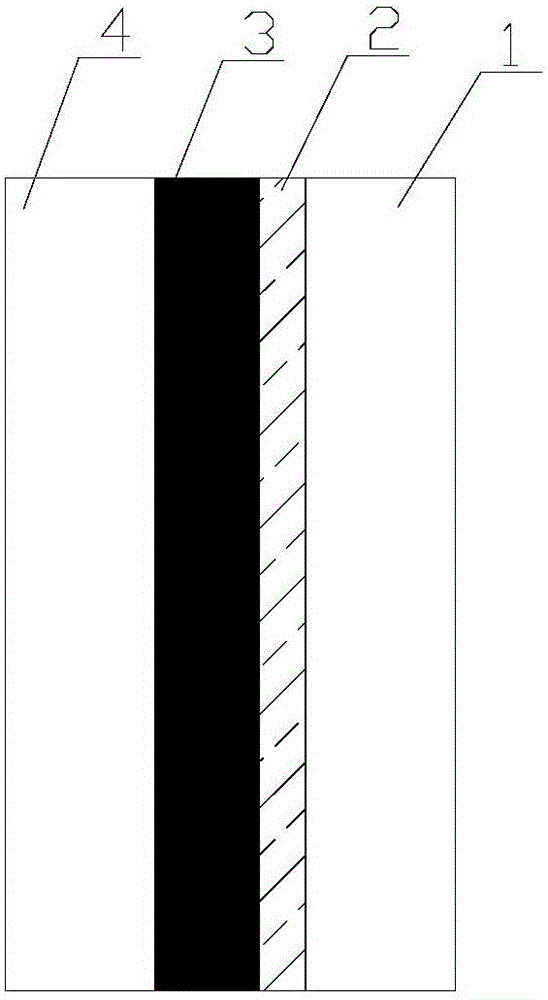

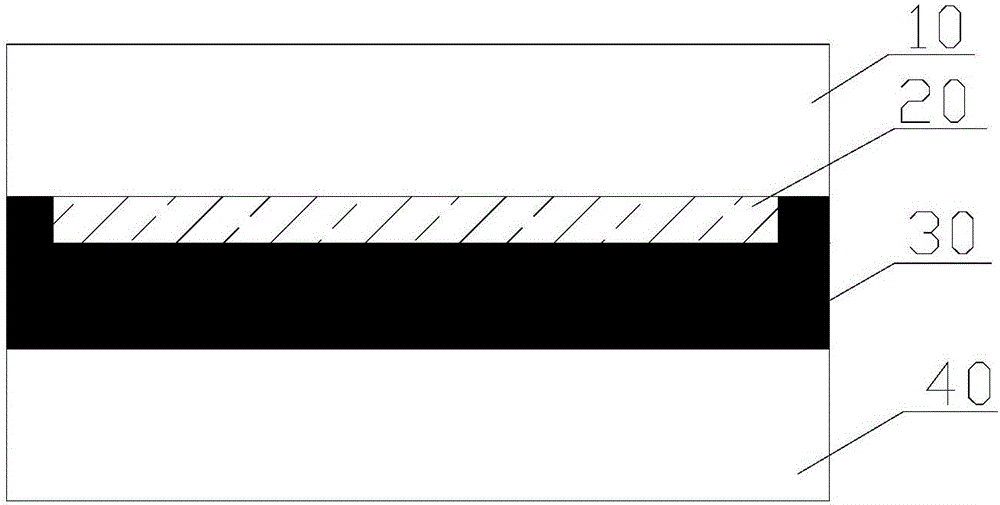

[0050] Such as figure 1 The smart dimming glass shown has a structure of a first glass layer 1 , a smart dimming layer 2 , an adhesive layer 3 , and a second glass layer 4 . Both the first glass layer 1 and the second glass layer 4 are 2mm ordinary non-stress strengthened transparent soda lime glass. The adhesive layer 3 is 0.76mm PVB. The intelligent dimming layer 2 is composed of a vanadium oxide material with phase change properties coated on a 30 μm thick PET substrate. The side of the intelligent dimming layer 2 coated with the vanadium oxide material is the same as the first The opposite side of the glass layer 1 is adhesive.

[0051] The manufacturing process of the laminated glass in this embodiment is as follows: place the first glass layer 1, attach the side of the intelligent dimming layer 2 coated with vanadium oxide material on the first glass layer 1, and lay the PVB adhesive layer 3 , to place the second glass layer. After being stacked in the above order, pre...

Embodiment 2

[0053] Compared with Example 1, the difference is that the vanadium oxide material in the intelligent dimming layer material is doped with W element at a concentration of 0.7 mol%, and the first glass layer and the second glass layer are respectively 6mm thick Green soda-lime tempered glass, doped vanadium oxide material is coated on a PET substrate with a thickness of 75 μm; after stacking each layer neatly in sequence, the laminated glass composite after preheating and rolling is sent into the autoclave 130 ℃, 1.3Mpa environment for 2 hours. The phase transition temperature of the laminated glass product in this example is 44°C.

Embodiment 3

[0055] Compared with Example 2, the difference is that the vanadium oxide material is doped with 0.6 mol% W and 0.8 mol% Mo, and the first glass layer and the second glass layer are 8mm thick transparent soda calcium Curved glass, doped vanadium oxide material is coated on a 100μm transparent PI substrate; after stacking each layer neatly in sequence, after vacuuming and pre-pressing edge sealing agent, it is sent to an autoclave at 140°C and 1.0Mpa for heat preservation 1.5 hours. In this embodiment, the phase transition temperature of the intelligent dimming layer in the laminated glass product is 39.5°C, and when the intelligent dimming layer (or laminated glass) reaches 50°C, the transmission adjustment rate at 1500nm reaches complete phase transition transparency. 87% of the over-regulation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com