Piezoelectric acceleration sensor prepared from nanometer barium titanate ceramic

An acceleration sensor and ceramic preparation technology, which is applied in the direction of using inertial force for acceleration measurement, etc., can solve the problems of reducing the dielectric constant, affecting the compactness of nano-barium titanate ceramics, affecting the ferroelectric performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

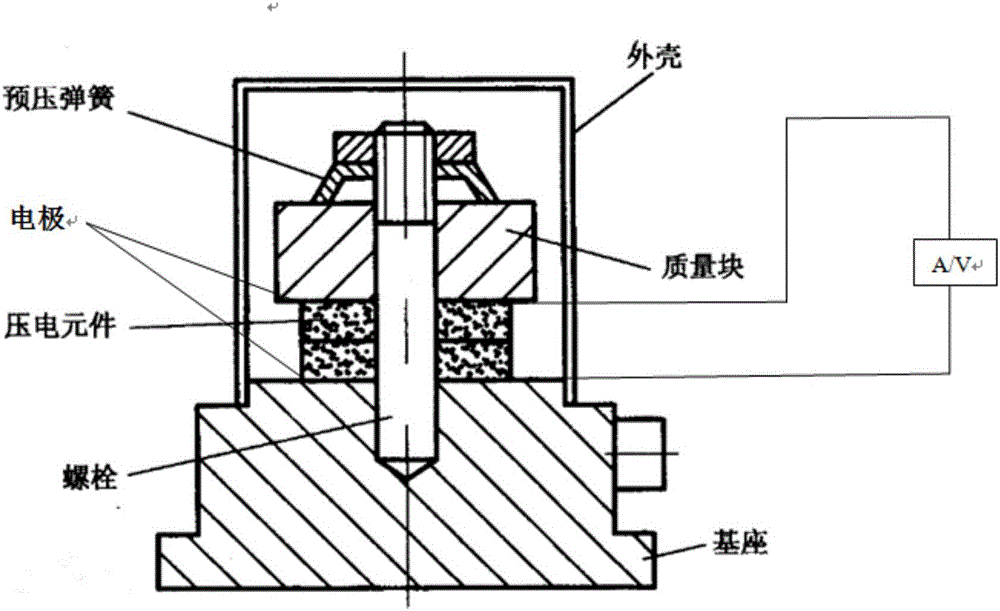

[0026] Such as figure 1 A piezoelectric acceleration sensor prepared using nano-barium titanate ceramics is shown, which includes a housing, a preloaded spring accommodated in the housing, a mass, piezoelectric elements made of nano-barium titanate ceramics, and bolts , the base, wherein electrodes are formed on the upper and lower surfaces of the piezoelectric element made of nano-barium titanate ceramics, and when the sensor is in motion, the pre-compressed spring deforms so that the mass presses the surface of the piezoelectric element, pressing The surface of the electrical element generates charges under the action of pressure, and the acceleration is detected by detecting the voltage or current generated when the piezoelectric element is stressed, wherein the nanometer barium titanate ceramic is prepared by the following steps:

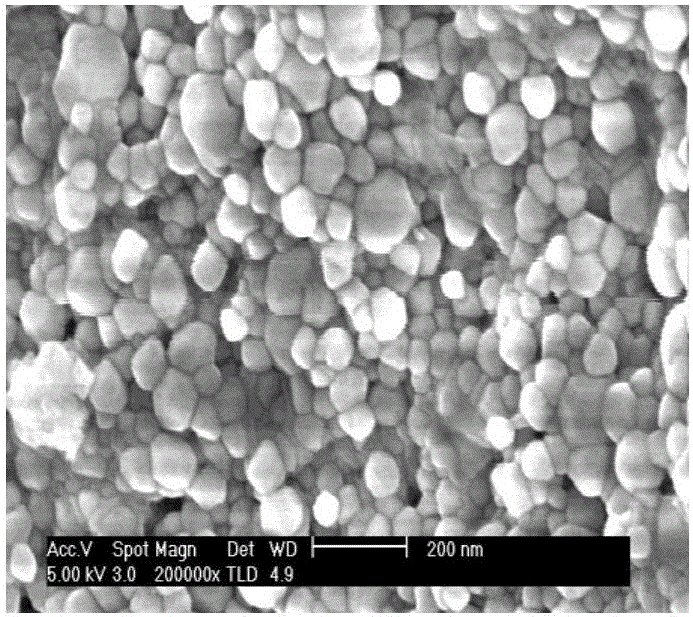

[0027] 1), at room temperature, use a steel mold to press the nano-barium titanate powder into a thin sheet with a pressure of 8Mpa on a tablet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com