Flint clay light porous ceramsite

A lightweight through-hole ceramsite and gemstone technology, applied in the field of ceramsite, can solve the problems of high specific gravity and bulk density, small effective specific surface area, and reduced adsorption capacity and water absorption of spherical ceramsite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with embodiment the present invention will be further described:

[0049] 1. The ingredients of burnt gem light through-hole ceramsite are composed of the following components by weight percentage: burnt gemstone 34%, high-viscosity attapulgite clay 24%, powdery burnt gemstone foaming agent 8%, activated clay waste residue 5% , floating beads 4%, light magnesium oxide 1%, expanded perlite 1%, expanded vermiculite 0.5%, ferrous sulfate 0.5%, quicklime 0% and water 22%.

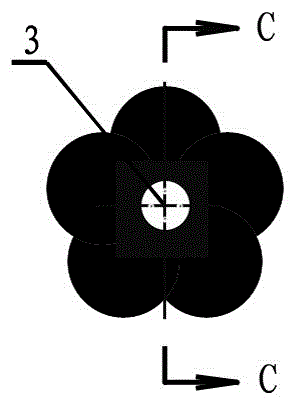

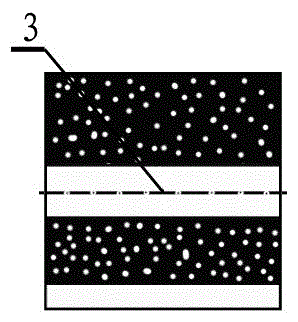

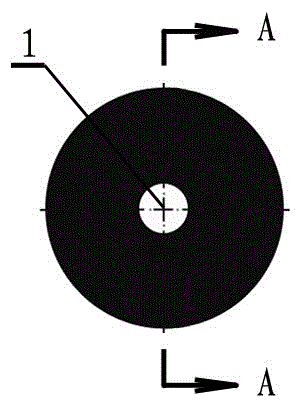

[0050] 2. The production method of burnt gem light through-hole ceramsite: (1) Input the ingredients of burnt gem light through-hole ceramsite into the running mixing mixer, and stir and mix it into a mixture of burnt gem light through-hole ceramsite; (2) Transport the mixture of burnt gem light through-hole ceramsite to the extrusion granulator, and extrude and granulate into different shapes of burnt gem light through-hole ceramsite semi-finished products; (3) burnt gem light throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com