A method for manufacturing a composite steel plate for a hydrogenation reactor cylinder

A technology of hydrogenation reaction kettle and clad steel plate, which is applied to manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of unsatisfactory working pressure, high production cost, limitation of large-size clad plates, etc., and achieves increased thermal insulation. The effect of improving time, bonding strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

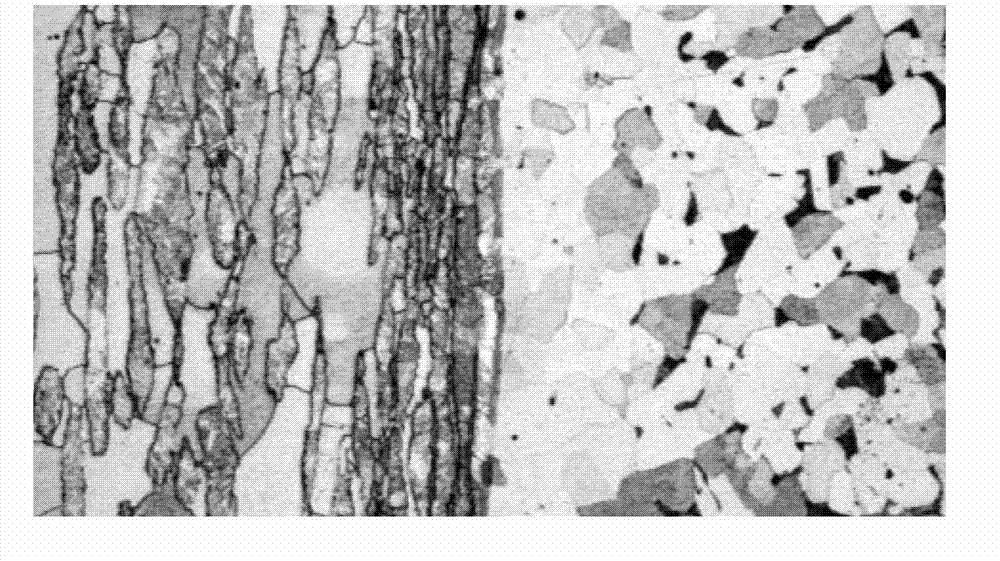

Image

Examples

Embodiment 1

[0027] Production of 100mm thick carbon steel-stainless steel clad steel plate for the cylinder of the hydrogenation reactor:

[0028] 1) A 300mm thick Q235B continuous casting slab and a 40mm thick 304 stainless steel billet are respectively selected as raw materials.

[0029] 2) The three sides of the selected continuous casting slab and stainless steel billet are respectively processed by flame cutting method, the groove depth is 25mm, and the groove angle is 25°.

[0030] 3) The blanks with the grooves are processed by a milling machine to remove iron oxide scale, oil stains, etc. on the surface, and the two blanks are processed into the same length and width.

[0031] 4) Stack the processed billets together, align them, and rotate the stacked continuous casting slabs by 90° and place them vertically before welding.

[0032] 5) The welding method of gas shielded welding is used to perform bottom welding on the three edge seams that have been processed. The diameter of the...

Embodiment 2

[0040] Production of 120mm thick carbon steel - composite steel plate for stainless steel hydrogenation reactor cylinder:

[0041]1) A continuous casting slab made of Q235B material with a thickness of 320 mm and a 304 stainless steel billet with a thickness of 40 mm were respectively selected as raw materials.

[0042] 2) The three sides of the selected continuous casting slab and the stainless steel billet are respectively processed by flame cutting method, the groove depth is 35mm, and the groove angle is 30°.

[0043] 3) Process the billet with the finished groove through a milling machine to remove the iron oxide scale, oil stains, etc. on the surface, and process the two billets into the same size.

[0044] 4) After the processed billets are stacked together, they are assembled and aligned, and the stacked continuous casting slabs are rotated 90° before welding and placed vertically.

[0045] 5) Adopt the welding method of gas shielded welding to carry out bottom weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com