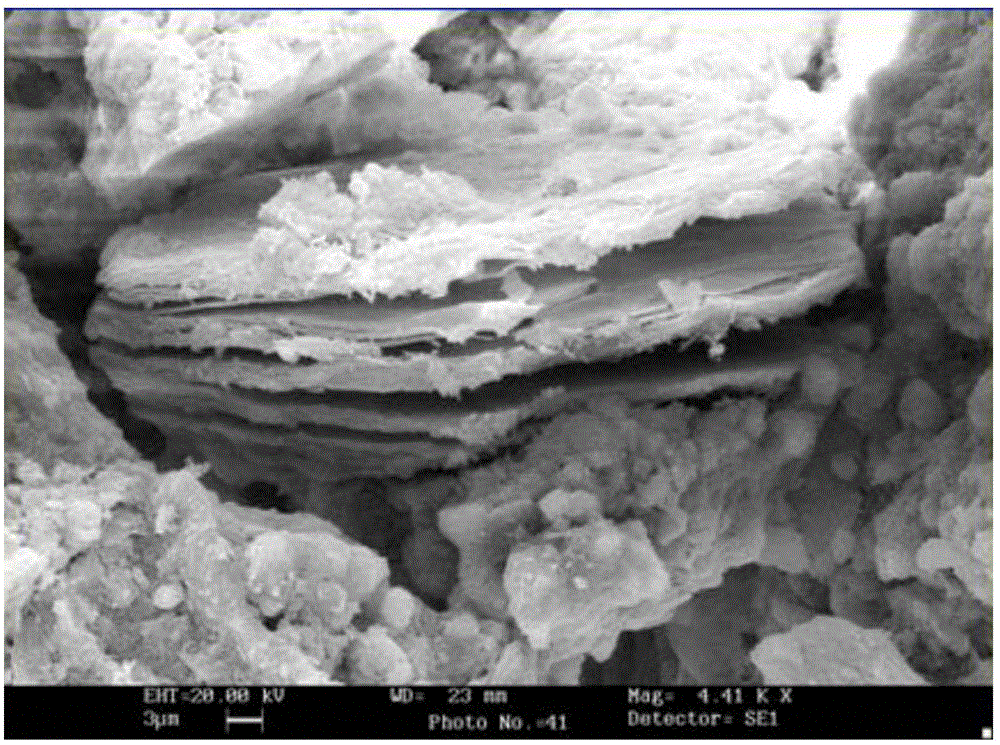

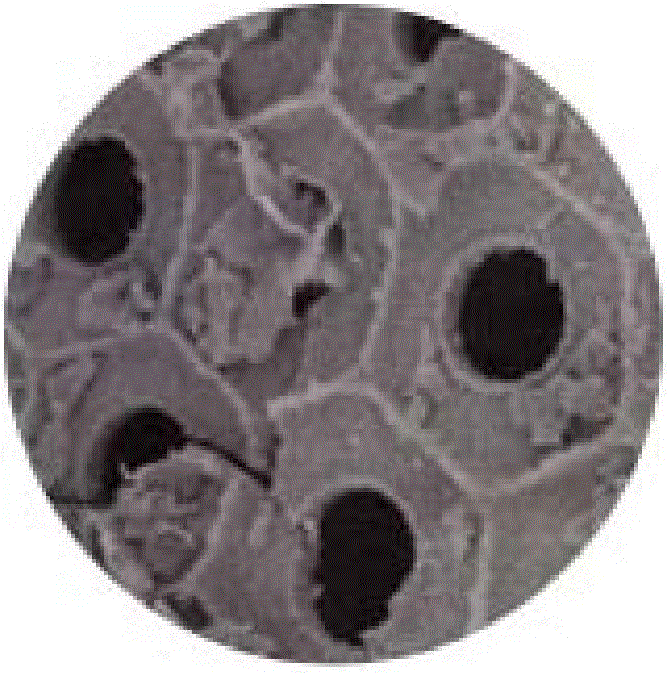

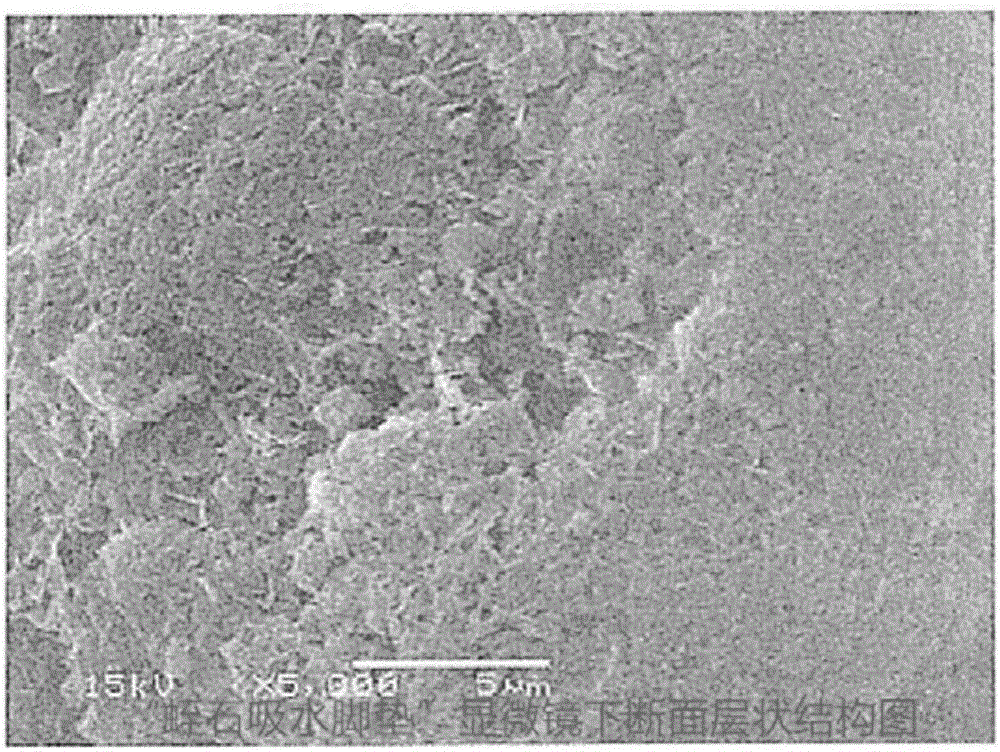

Vermiculite-kieselguhr compounded water absorption foot pad and preparing method thereof

A diatomite and vermiculite technology, applied in the field of composite materials, can solve the problems of easy deformation and discoloration, easy breeding of mites and bacteria in chemical fiber products, and achieve the effect of easy operation and enhanced adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The vermiculite diatomite composite water-absorbing mat provided in this example is made of the following raw materials:

[0058] 40 parts of diatomite, 10 parts of expanded vermiculite, 15 parts of calcium hydroxide and 5 parts of wood pulp fiber.

[0059] The preparation method of this vermiculite diatomite composite water-absorbing foot pad comprises the following steps:

[0060] The wood pulp fiber and expanded vermiculite are prepared into paper pulp and vermiculite pulp by pulping process respectively; vermiculite pulp, diatomaceous earth and calcium hydroxide are added to the debonded pulp in turn, and pulping and pre-mixing are carried out; The pre-mixed slurry is subjected to plate making, billet joining, and stacking to obtain slabs, and the slabs are autoclaved and cured, and then demolded and dried to obtain the vermiculite diatomite composite water-absorbing mat.

Embodiment 2

[0062] The vermiculite diatomite composite water-absorbing mat provided in this example is made of the following raw materials:

[0063] 70 parts of diatomite, 25 parts of expanded vermiculite, 30 parts of calcium hydroxide and 20 parts of wood pulp fiber.

[0064] The preparation method of this vermiculite diatomite composite water-absorbing foot pad comprises the following steps:

[0065] Add the wood pulp fiber into the vertical pulper, add water to loosen it for 40 minutes; add water to the expanded vermiculite and grind it to make the particle size less than 0.75 mm, and make pulp to obtain vermiculite pulp; add it to the loosened pulp in turn Vermiculite slurry, diatomaceous earth (40 microns in particle size) and calcium hydroxide are used for refining and pre-mixing; the pre-mixed slurry is used for board making, the board length is 2.4 meters, and the board width is 1.2 meters. Stacking to obtain slabs, performing pre-maintenance on the stacked slabs, autoclaving and...

Embodiment 3

[0069] The vermiculite diatomite composite water-absorbing mat provided in this example is made of the following raw materials:

[0070] 50 parts of diatomite, 15 parts of expanded vermiculite, 15 parts of calcium hydroxide and 5 parts of wood pulp fiber.

[0071] The preparation method of this vermiculite diatomite composite water-absorbing foot pad comprises the following steps:

[0072] Add wood pulp fibers into a vertical pulper, add water to loosen and dissolve for 50 minutes; add water to grind expanded vermiculite to make the particle size 0.2-0.75 mm, and make pulp to obtain vermiculite pulp; loosen the pulp Add vermiculite slurry, diatomaceous earth (50 microns in particle size) and calcium hydroxide in sequence, and carry out refining and pre-mixing; prepare the pre-mixed slurry, the length of the board is 2.5 meters, and the width of the board is 1.3 meters. Blanks and stacking to obtain slabs, pre-maintaining the stacked slabs, autoclaving and curing the slabs, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com