COREX smelting reduction iron making equipment and iron making method

A technology of equipment and reduction furnace, applied in COREX smelting reduction ironmaking equipment and ironmaking field, can solve the problems of large heat loss, long time consumption, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

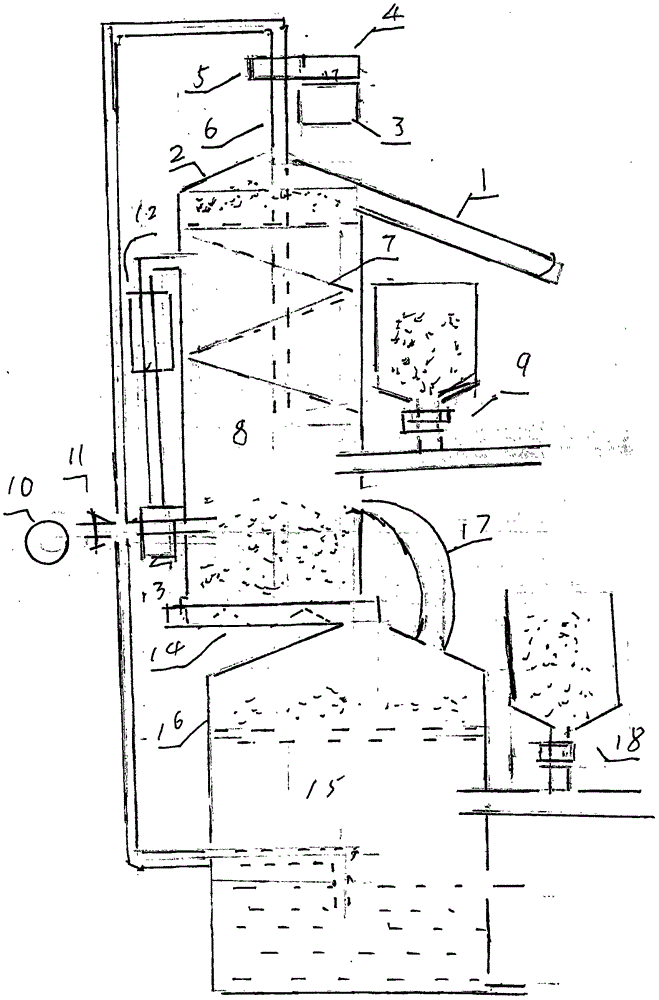

[0009] figure 1 As shown, a kind of COREX smelting reduction ironmaking equipment of the present invention is mainly composed of: shaft furnace reduction shaft furnace 8, distributed raw material feeding device 2, screw extruded sponge iron conveyor 14, melting gasifier 15, raw material conveyor 1, A bag filter 12 woven by ceramic fiber, a hot blast stove 13, a carbon monoxide generator 10 and a carbon monoxide compressor 11 are composed. The principle of COREX ironmaking is as follows: use the raw material conveyor 1 to transport the iron ore powder, pulverized coal and flux to the distributed raw material feeding device 2, and put the iron ore powder, fine coal and flux (limestone and quartz) through the distributed raw material feeding device The device 2 is put into the shaft furnace reduction furnace intermittently. After the carbon monoxide produced by the carbon monoxide generator 10 is compressed by the carbon monoxide compressor 11, the first part of carbon monoxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com