Whole-bundle drawing device assembly for replacing hoisting rod and cleaning hole and steel wire and hole cleaning method for detaching old hoisting rod of arch bridge thereof

A technology of drawing device and suspender, which is applied in the field of old suspender dismantling, steel wire drawing and hole cleaning device, which can solve the problems of long construction work time, high construction cost and high manual work intensity, and achieve short construction work time , Low manual work intensity, easy to standardize the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

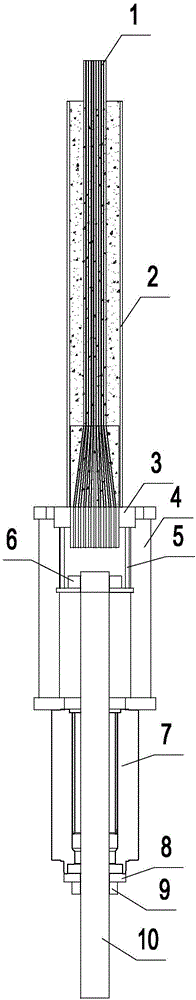

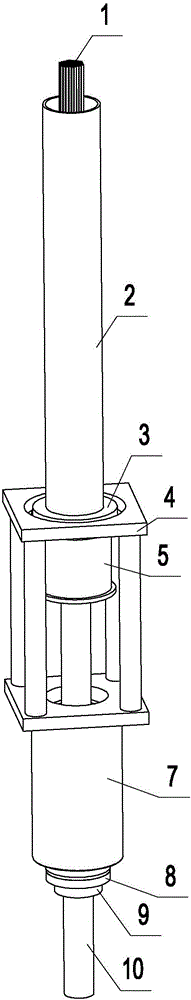

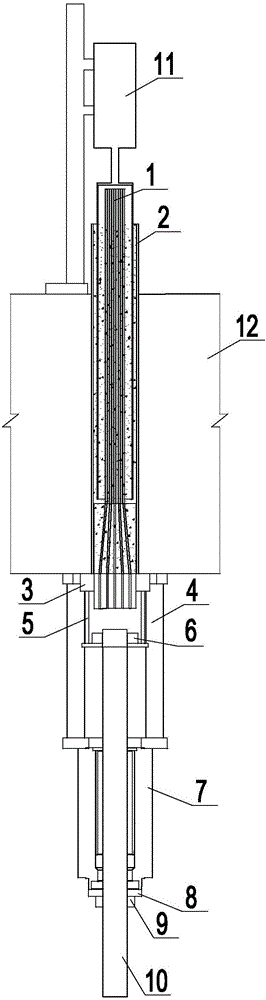

[0029] A whole-bundle drawing device assembly for boom replacement and hole cleaning, such as figure 1 , figure 2 As shown, the device assembly includes a connector 5, a tool nut I6, a high-strength screw rod 10, a support foot 4, a tension jack 7 and a tool nut II9;

[0030] There are round holes at both ends of the connector 5, and the tension jack 7 is a through-hole jack;

[0031] In use state: the round hole at the upper end of the connector 5 is set on the anchor plate of the steel wire anchor head to be drawn and fixedly connected with it by welding, and the round hole at the lower end of the connector 5 is covered with the high-strength screw 10, and one end is threaded through the tool nut I6. Fixedly connected with it, the support foot 4 is installed on the bottom of the beam under the bridge as a reaction support frame of the tension jack 7, the upper end of the tension jack 7 is installed under the support foot 4, and the lower end of the tension jack 7 passes th...

Embodiment 2

[0033] A steel wire and hole-clearing method for removing old suspenders of arch bridges, which uses the "a whole-bundle drawing device assembly for replacing suspenders for hole cleaning" described in Embodiment 1 to implement whole-bundle drawing for the removal of old suspenders of arch bridges The construction method of drawing steel wire and clearing the hole, that is: first use a concrete core drilling rig to drill a hole from top to bottom on the bridge deck to the anchor head section of the old suspender, then install the device assembly under the bridge deck, and use a hydraulic tensioning jack The driving force is provided, and the high-strength screw is used as the jack tensioning part; the high-strength screw and the steel wire anchor head of the old suspender of the arch bridge to be drawn are fixedly connected by a connector; the steel wire or After the anchor head of the steel strand, the hole should be cleared at last. The specific steps are:

[0034] A, drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com