Box girder unbonded prestressing and steel plate-concrete combination reinforcing design method

A prestressed steel bar, non-bonded technology, used in bridge reinforcement, bridge construction, bridges, etc., can solve problems such as high maintenance costs, unreasonable bridge stress, and poor mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Such as figure 1 The design method for the unbonded prestressed and steel plate-concrete combination reinforcement of a box girder includes the following steps:

[0089] Step 1. Determination of combined reinforcement structure: determine the unbonded prestressed and steel plate-concrete combined reinforcement structure of the reinforced box girder 6; the reinforced box girder 6 is a prestressed concrete beam;

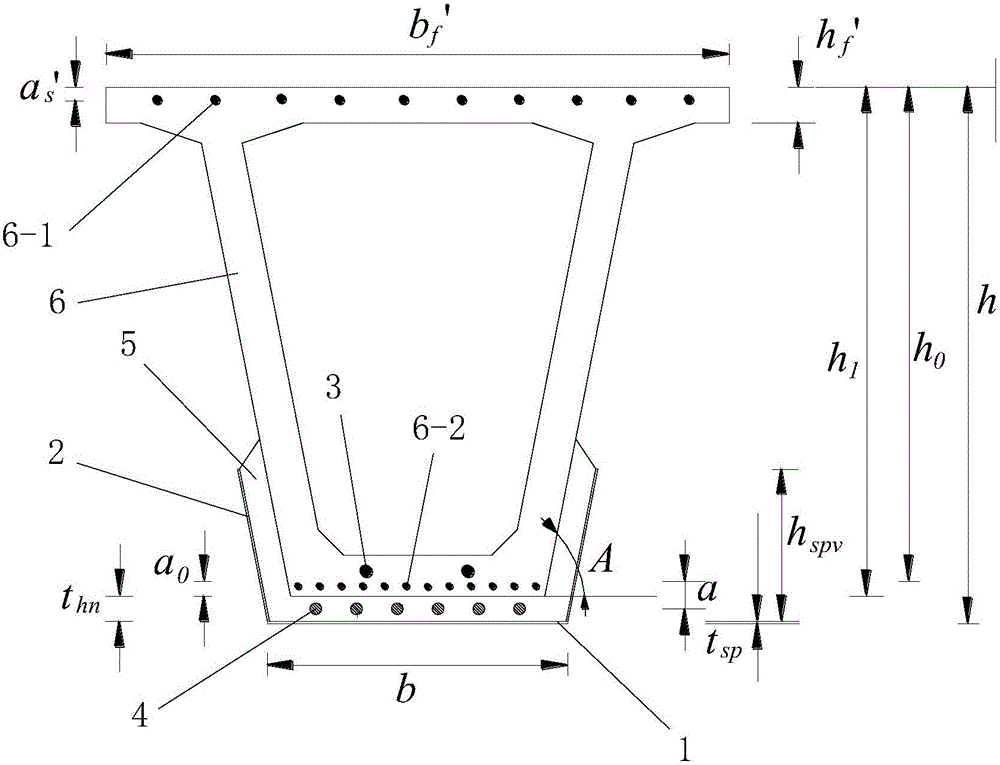

[0090] Such as figure 2 As shown, the combined reinforcement structure of unbonded prestress and steel plate-concrete includes a bottom steel plate 1 arranged under the area to be reinforced of the box girder 6 to be reinforced, and two longitudinal steel plates arranged on the left and right sides of the area to be reinforced respectively. The side steel plates 2 and two end-blocking steel plates respectively arranged at the front and rear ends of the area to be reinforced, the bottom steel plate 1 and the two longitudinal side steel plates 2 are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com