Prefabricating, floating transporting and fitting-out technology for steel shell immersed tunnel pipe sections

A steel shell immersed tube and tunnel tube technology, which is applied in the field of steel shell immersed tube tunnel joint prefabrication and floating outfitting technology, can solve the risks of dredging construction with many cross-working surfaces, large environmental impact of dredging channel, and return of deep channel and other problems, to achieve the effect of simple construction organization, small environmental impact, small weight and draft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments.

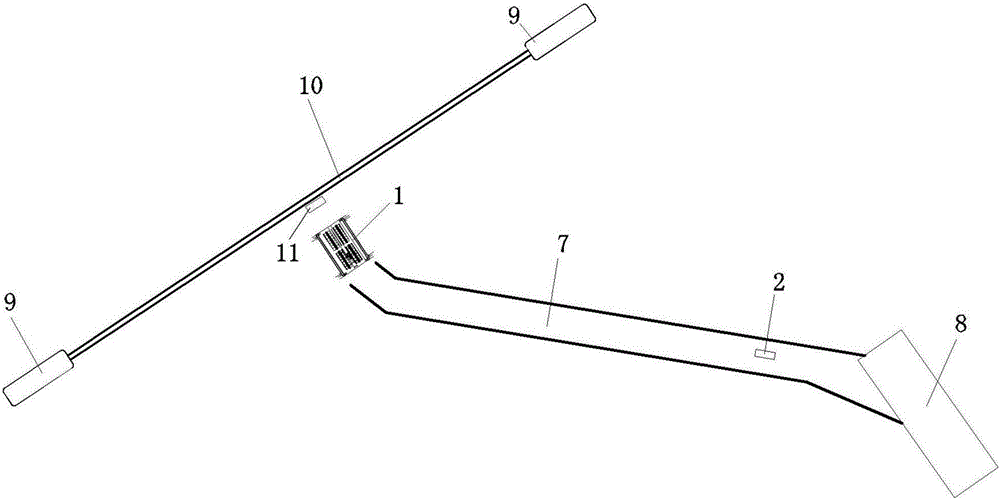

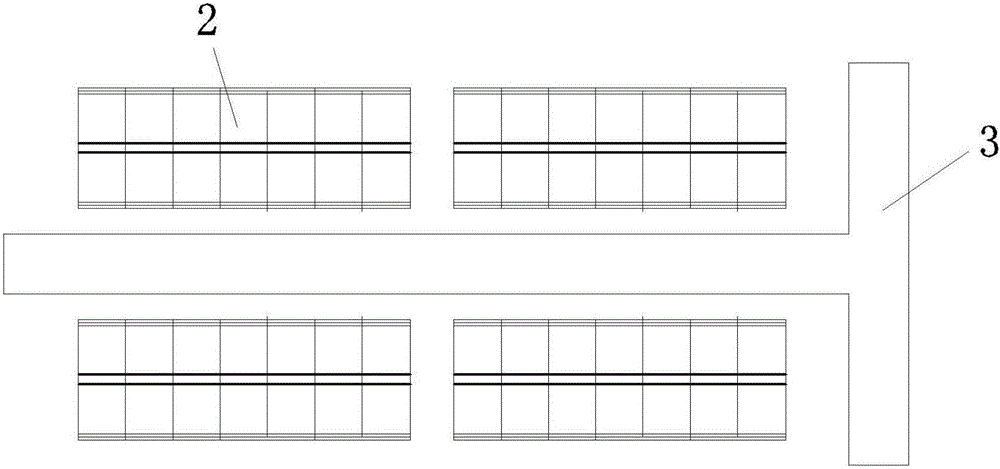

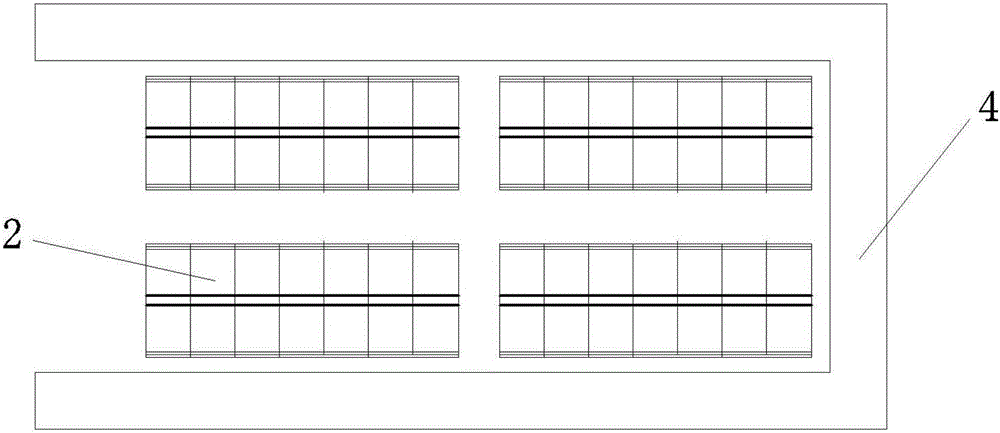

[0032] like figure 1 As shown, between the two artificial islands 9, a subsea tunnel is to be built along the tunnel route 10. The prefabricated floating outfitting process for the steel shell immersed tube tunnel section of the present invention includes the following steps. The shell manufacturing plant 8 completes the manufacture of the steel shell 2 of the tunnel pipe section 11; floats the manufactured steel shell 2 along the waterway 7 to the concrete pouring and outfitting wharf at the tunnel site; Concrete pouring and outfitting are performed on the steel shell to complete the manufacture of the tunnel pipe joint 11; the prepared tunnel pipe joint 11 is transported to the sinking position for sinking and installation.

[0033] The invention mainly divides the tunnel pipe joint into two parts for construction. The first part is steel shell manufacturing. A steel she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com