Piston for internal combustion engine

A technology for internal combustion engines and pistons, applied to pistons, mechanical equipment, engine components, etc., can solve the problems of difficult formation of liquid lubricating oil film, uncoordinated bending and deformation, and low relative speed between piston pin and pin seat, so as to improve thermal efficiency and engine Economical, avoid deformation and strain, improve the effect of tumble ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

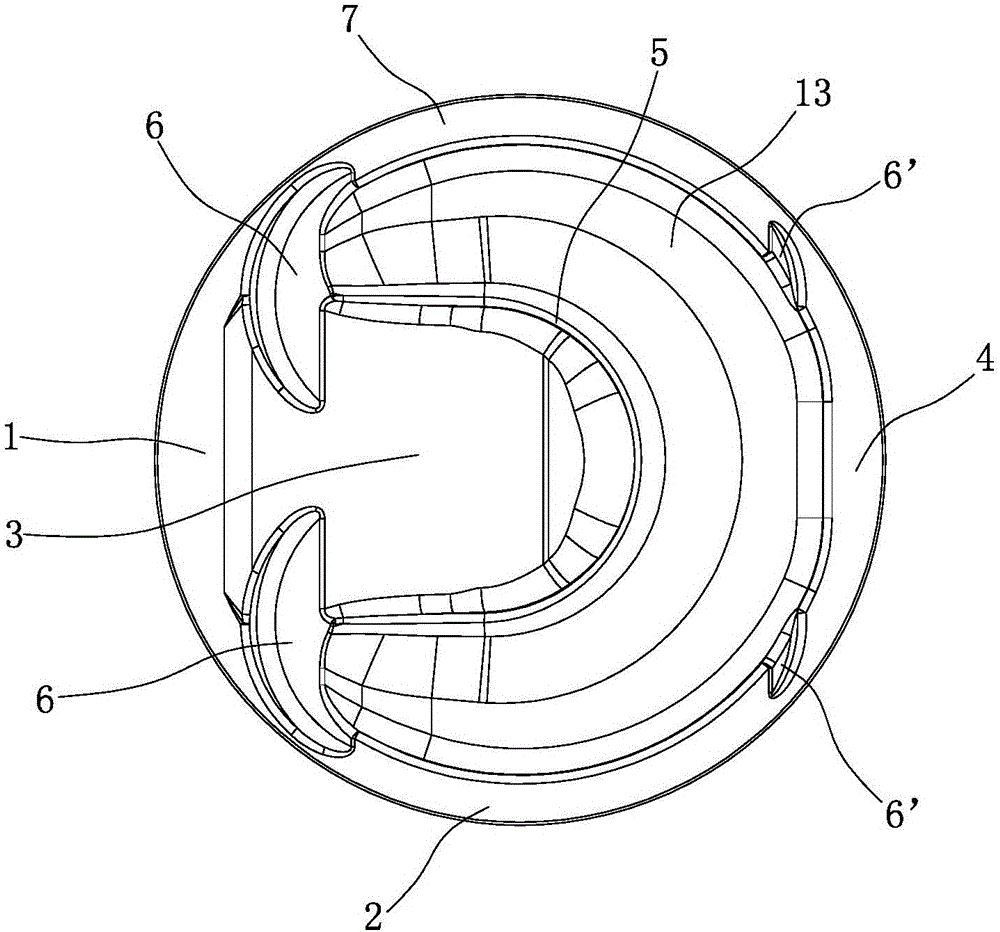

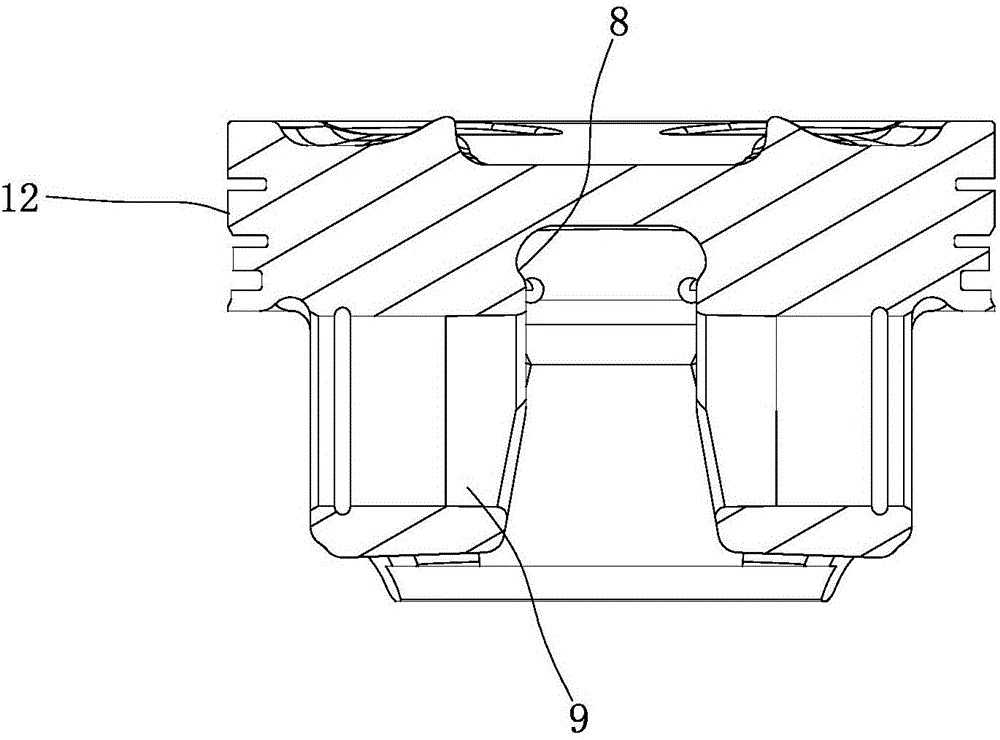

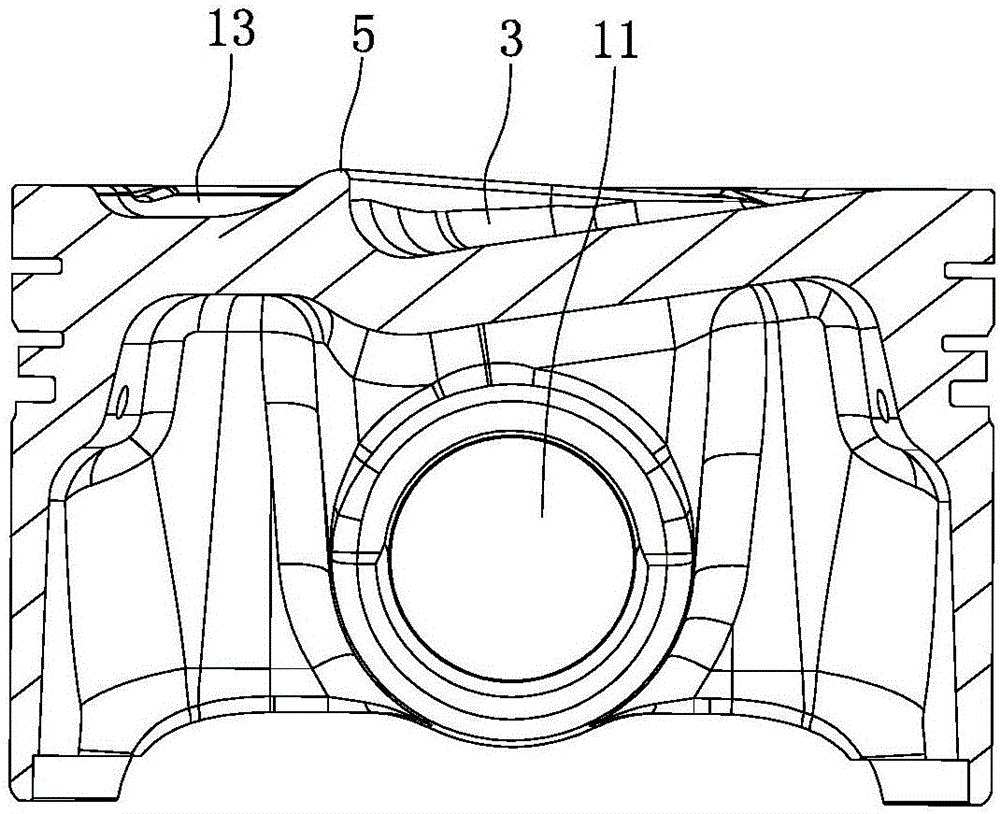

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the internal combustion engine piston includes a piston top, a piston skirt 12, a piston pin seat 9 and a piston pin hole 11, and a graphite coating is provided on the outer wall of the piston skirt 12. There is a "U"-shaped boss 5 on the top of the piston, and the "U"-shaped boss 5 is 0.5mm-2.0mm higher than the upper surface of the cylinder block. The area surrounded by the "U"-shaped boss 5 forms a pit 3, the bottom surface of the pit 3 is a slope, and the inclination angle of the bottom surface of the pit 3 is 8°-10°. The depth of the pit 3 gradually increases from front to back, and the value is 2.5mm-7.0mm. The inner sidewall of the pit 3 is an oblique cone surface, and the bottom surface of the pit 3 and the inner sidewall are transitioned through rounded corners.

[0022] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com