Hydraulic control loop for garbage truck

A control circuit and hydraulic technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc., can solve the problems of rising load pressure, easy failure of seals, and aggravated wear between parts, so as to reduce jamming Possibility of valve, improvement of heat dissipation effect, effect of reducing motion shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

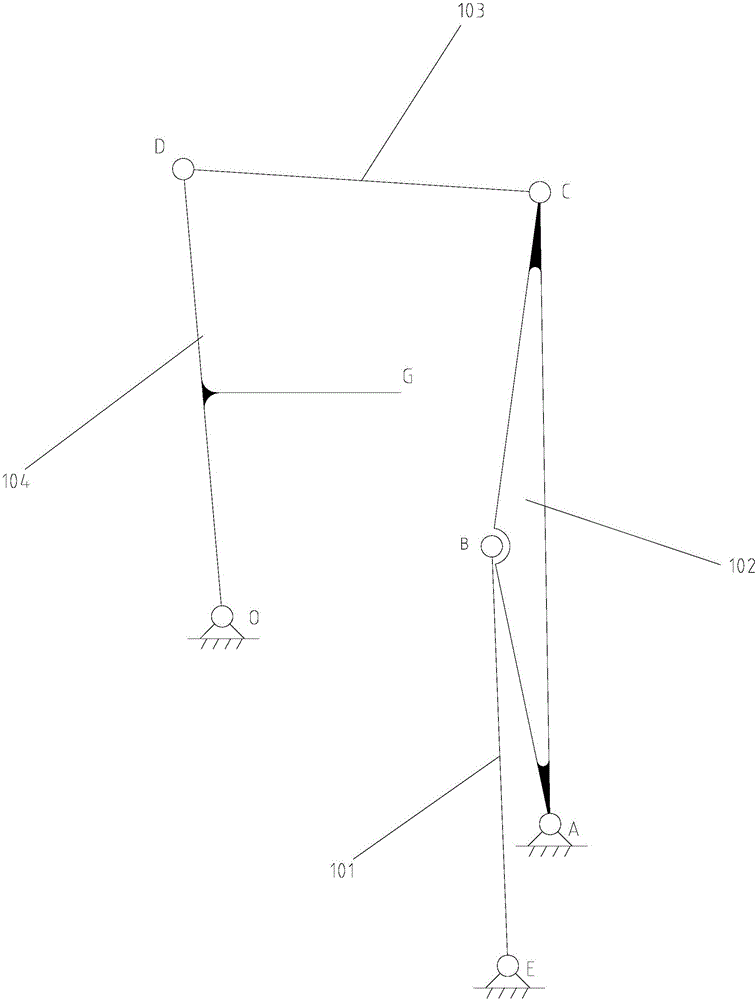

[0035] Such as figure 1The above is a schematic structural diagram of the feeding mechanism of the intelligent garbage truck. One end E of the cylinder piston rod is a fixed end, which is hinged with the vehicle body frame, and the other end B is the movable end of the piston rod, which is hinged with the swing rod 102. , one fixed end A of the swing rod 102 is hinged with the vehicle body frame, the other fixed end C is hinged with one end of the connecting rod 103, the other fixed end D of the connecting rod 103 is hinged with a fixed end of the hopper, and the hopper is simplified as A pendulum is hinged with the O end on the frame and can rotate around the O end. Point G is the center of gravity of the hopper. The position of the hopper 104 in the figure is the position when the lifting is complete. At this time, the position of the cylinder piston rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com