Building block system low air-resistor condenser assembly and technology

A building block and condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as increased air resistance, save transportation costs, low material and processing costs, and save installation work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

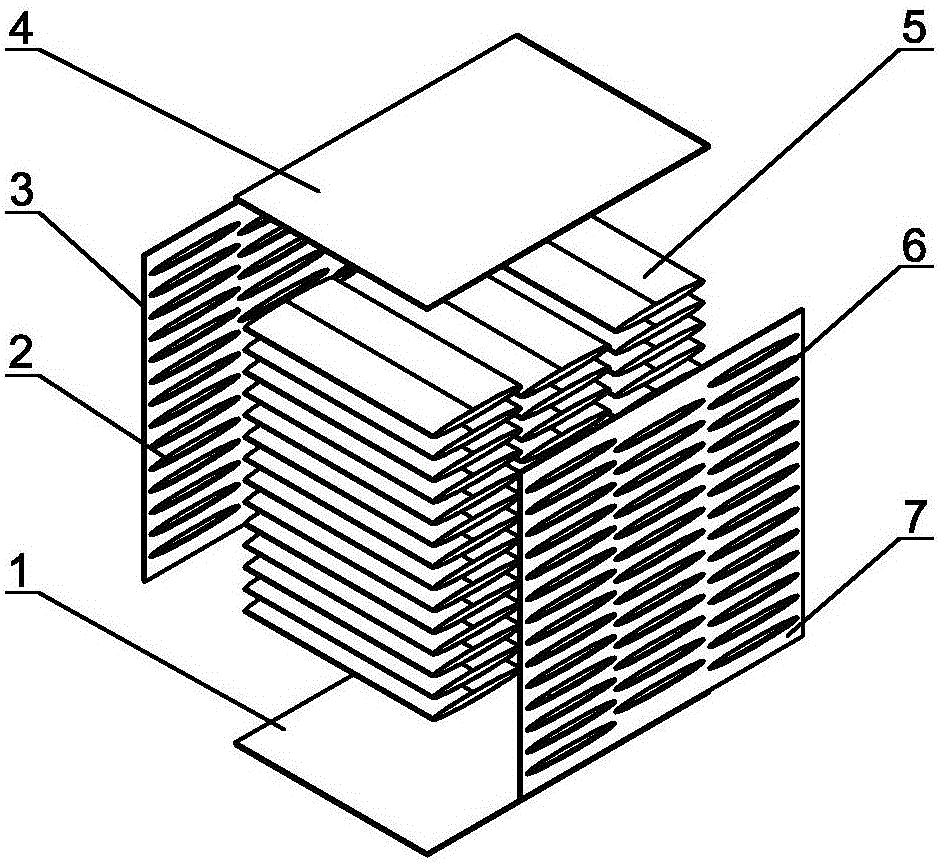

[0022] combined with figure 1 The structure of the present invention is illustrated:

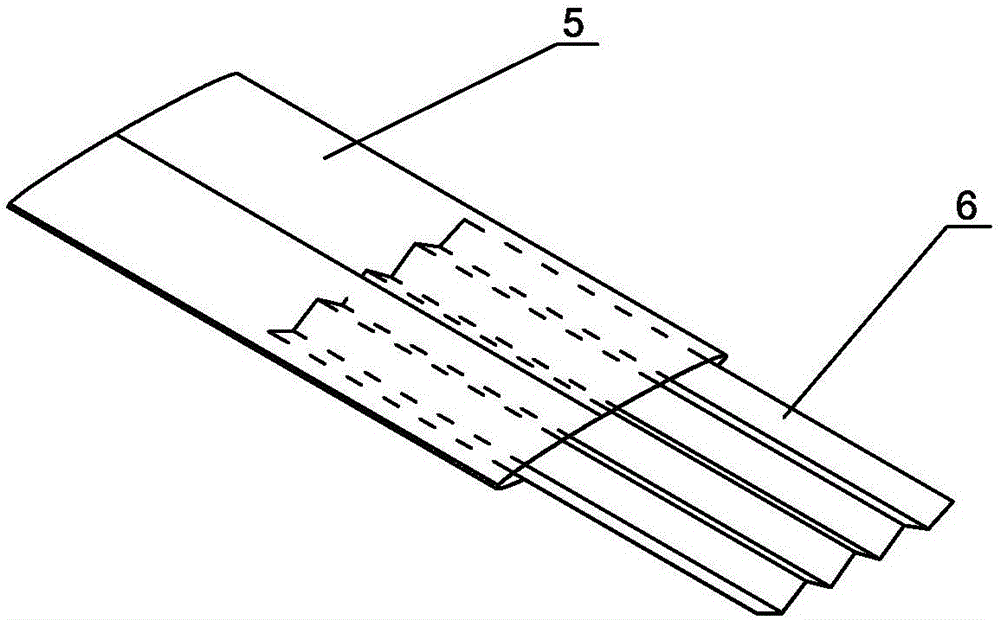

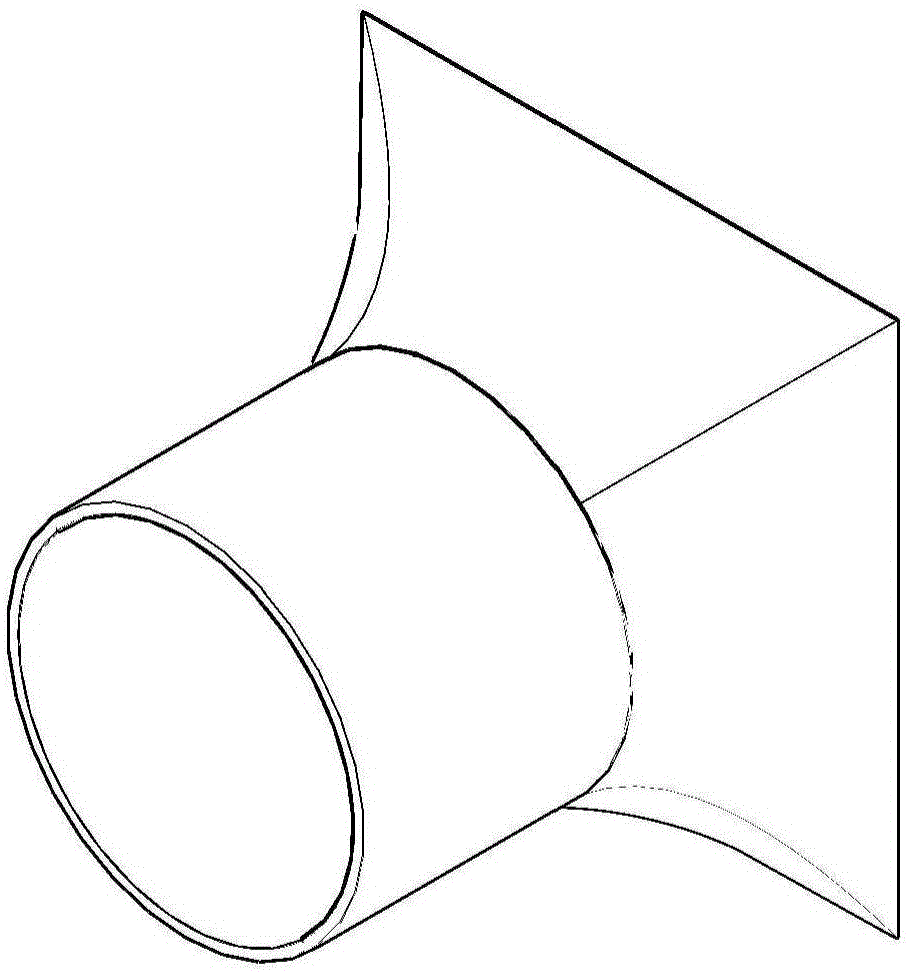

[0023] In order to achieve the purpose of the above invention, the specific method is to use stainless steel sheet material. In consideration of the domestic use of the converted hot water, the material is 304 food-grade stainless steel. First, the stainless steel sheet material is stamped into a fish-shaped heat exchange pipe through a mechanical mold. (5), inside the pipeline such as figure 2 An inner support plate (6) stamped and formed by a stainless steel sheet is installed, and an array of fish-shaped heat exchange pipes (5) are arranged in groups. (2) Pass through the right diversion hole (7) of the right baffle (8), and the left and right baffles (3) (8) are respectively made of composite steel plates composed of carbon steel plates and stainless steel plates. In order to ensure accurate Assembling accuracy, cutting the outer dimensions of the steel plate and opening the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com