Manufacturing method of luneberg lens antenna

A technology of Lunberg lens antenna and manufacturing method, which is applied to antennas, electrical components, etc., can solve the problems of the deviation of the dielectric constant of the lens layer and the design value, the influence of the working performance of the lens antenna, and the deviation of the change of the dielectric constant, etc., and achieve compactness. High, structural integrity, uniform density effect

Inactive Publication Date: 2016-11-09

深圳贝斯特网联通讯设备有限公司

View PDF3 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the production process of the traditional Lunberg lens antenna, the dielectric constant of each lens layer generally has defects that are difficult to control, which leads to a large deviation between the dielectric constant of each lens layer and the design value, resulting in the production of the Lunberg. The variation of the dielectric constant of the Lunberg lens deviates from the ideal change law, which eventually leads to the serious impact on the performance of the lens antenna assembled by the Lunberg lens

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0072]

[0073]

Embodiment 2

[0075]

[0076]

[0077]

Embodiment 3

[0079]

[0080]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

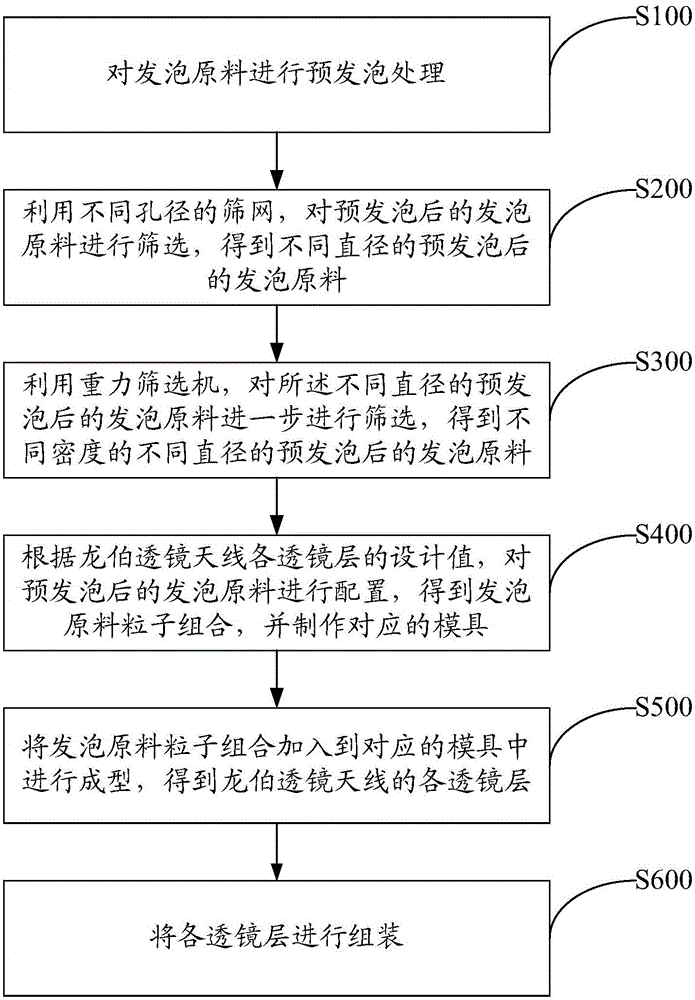

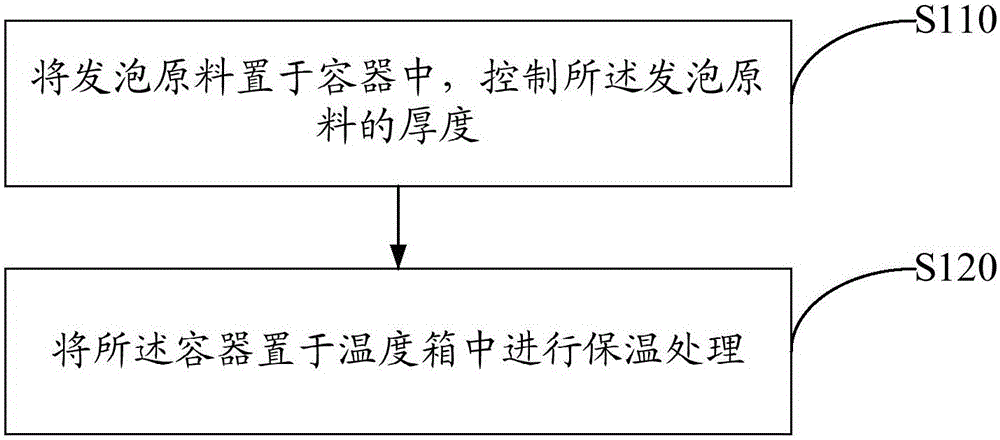

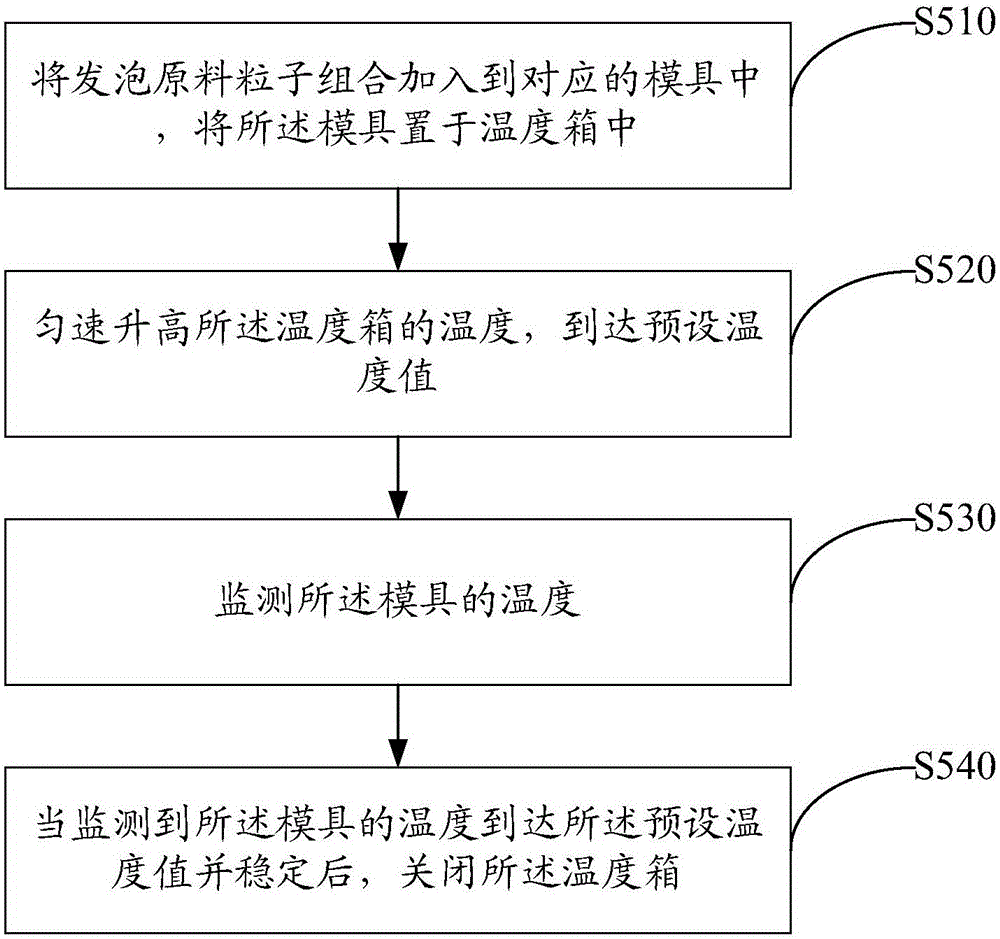

The invention discloses a manufacturing method of a luneberg lens antenna. The method comprises the following steps of carrying out pre-foaming treatment on a foam material; preparing the pre-foamed foam material according to design values of various lens layers of the luneberg lens antenna to obtain foam a material particle composition and manufacturing a corresponding mold; adding the material particle composition to the corresponding mold for molding to obtain the lens layers of the luneberg lens antenna; and assembling the lens layers. According to the technical scheme, the accuracy of dielectric constants of the lens layers of a luneberg lens can be improved; and the change of the dielectric constants of the luneberg lens is closer to the ideal change rule, so that the working performance of the luneberg lens antenna is improved.

Description

technical field [0001] The invention relates to a manufacturing method of a Lunberg lens antenna. Background technique [0002] At present, the Lunberg lens antenna is widely concerned and used by people because of its many characteristics superior to the parabolic antenna. Theoretically, in order to realize the ideal working performance of the Lunberg lens antenna, the dielectric constant of the Lunberg lens, an important component, should change in an ideal law, that is, the dielectric constant changes continuously and smoothly from the core to the outer layer, from 2 to 1. At present, in order to realize the ideal variation of the permittivity of the Lunberg lens, a common method is to use a plurality of lens layers whose diameters gradually change and the permittivity also gradually changes to be stacked concentrically. However, in the production process of the traditional Lunberg lens antenna, the dielectric constant of each lens layer generally has defects that are di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01Q15/08

Inventor 岑建立

Owner 深圳贝斯特网联通讯设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com