2P high-speed copper bar rotor low vibration insurance structure

A low-vibration, copper-bar technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electric components, etc., can solve the problems of alarm shutdown, production stoppage, vibration exceeding limit, insufficient reliability, etc., to ensure safety. Operation, reliability enhancement, dynamic stability enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

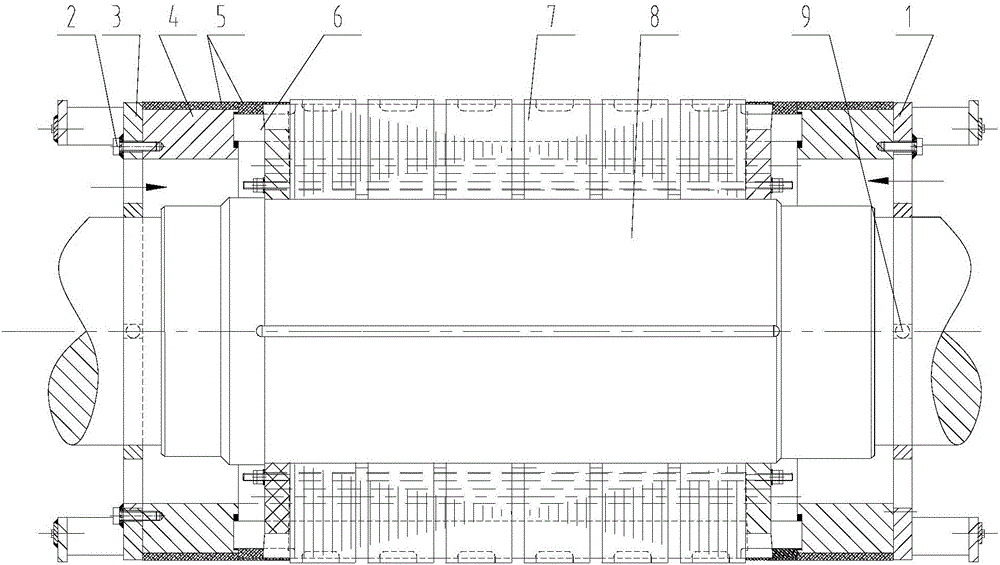

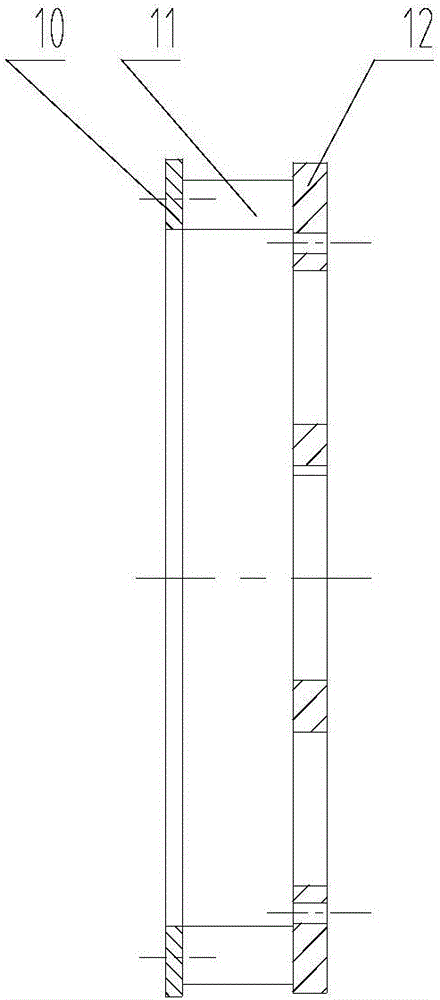

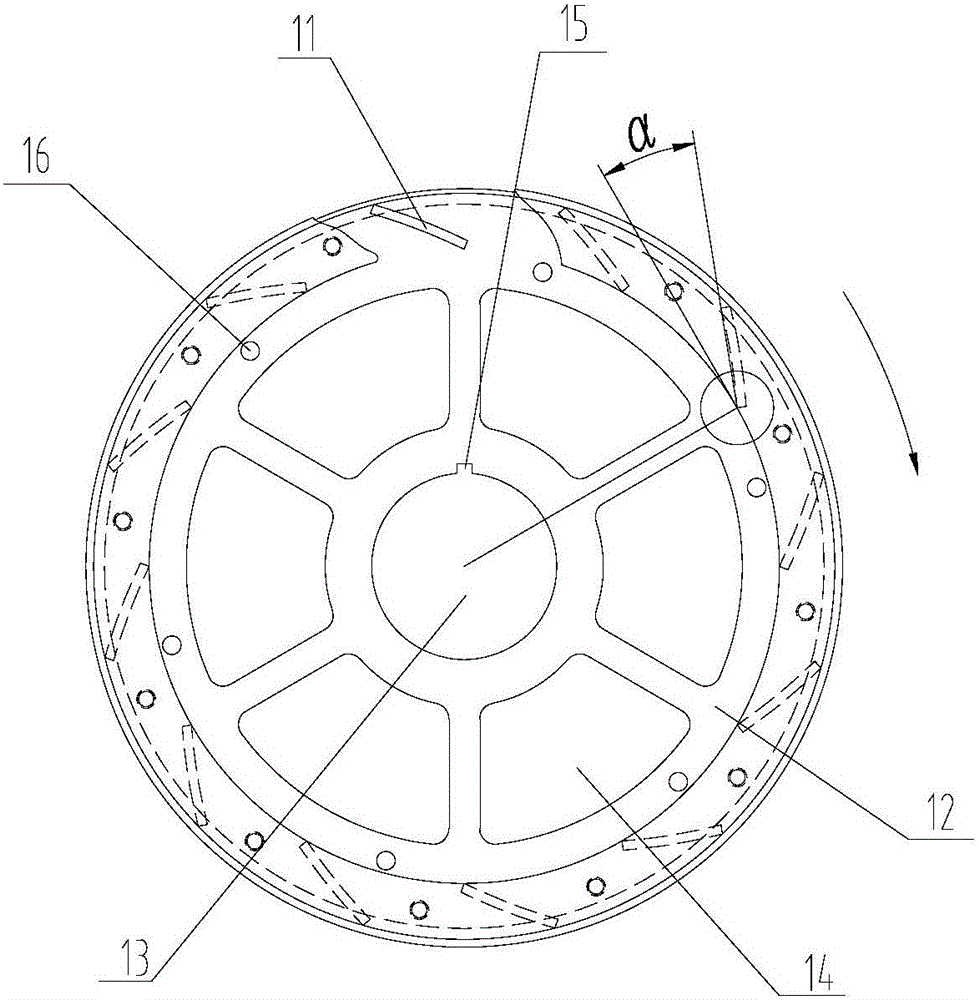

[0027] This embodiment describes a low-vibration safety structure for a 2P high-speed copper bar rotor, such as Figure 1-3 As shown, it includes a copper bar rotor 8. The outer sides of both ends of the copper bar rotor 8 are connected to the left fan 3 and the right fan 1 respectively. The copper bar rotor 8 has a plurality of rotor copper bars 6 inserted in the groove shape, The rotor copper bar 6 penetrates into a rotor iron core 7 and is hammered and tightened in the axial full length of the core part. The two ends of the rotor copper bar 6 are respectively bound by a mesh latitude belt 5 and clamped to one end. Ring 4, the outer end surface of the end ring 4 on the left side of the copper bar rotor 8 is tightly connected to the left fan 3, and the outer end surface of the end ring 4 on the right side of the copper bar rotor 8 is tightly connected to the right fan 1 The left fan 3 and the right fan 1 have the same structure and opposite rotation directions. The left fan 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com