Semiconductor thermoelectric power generation component

A technology of thermoelectric power generation and semiconductor, which is applied in the direction of electrical components, thermoelectric devices, thermoelectric device parts, etc., can solve the problems of thermoelectric power generation components contact thermal resistance cold end cooling, etc., to improve thermal stability and power generation efficiency, and improve mechanical strength , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

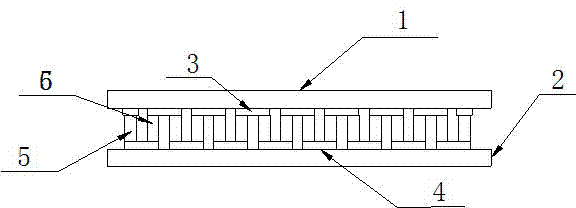

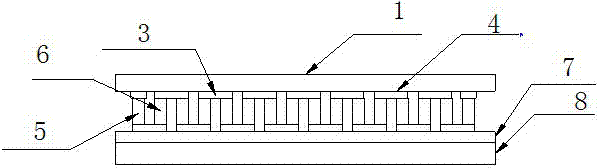

[0027] In the original thermoelectric power generation components (such as figure 1 ) on the basis of a thermoelectric power generation assembly of the present invention (such as figure 2 ) The aluminum alloy substrate 8 is used to replace the traditional alumina ceramic substrate 2, the hot end is coupled to the heat source through the alumina ceramic substrate 1, and the alumina ceramic substrate is welded to the outer side of the copper guide sheet 3 on the hot surface using high-temperature solder. At the cold end, the high-temperature solder 4 is replaced by a high-thermal-conductivity insulating double-sided adhesive 7 so that the aluminum alloy substrate 8 is connected to the outer side of the cold-side copper flow deflector. Use high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com