Formulations of luminescent compounds

A technology of luminescent compounds and preparations, applied in the application of luminescent coatings, luminescent materials, luminescent coatings, etc., can solve the problems of rare iridium and platinum, expensive metals, and damage to the economy of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0167] determination method

[0168] Determine HOMO, LUMO, singlet and triplet energy levels

[0169] The energy levels of the molecular orbitals and the lowest triplet state T of the material 1 or the lowest excited singlet state S 1 The energy of is determined by quantum chemical calculations. The program package "Gaussian09, Revision D.01" (Gaussian AG) was used for this purpose. To calculate metal-free organic species (labeled with the "org." method), first, a geometry optimization is performed with the semi-empirical method AM1 (Gaussian input line "#AM1opt") with Charge 0 and Multiplicity 1 . Subsequently, energy calculations (single point) for the electronic ground state and triplet state are performed based on the optimized geometry. Here the TDDFT method (time-dependent density functional theory) B3PW91 (charge 0, multiplicity 1) with basis set 6-31G(d) (Gaussian input line "#B3PW91 / 6-31G(d)td= (50-50, nstates=4)"). The geometry (charge 0, multiplicity 1) was opt...

example 2

[0191] Device example

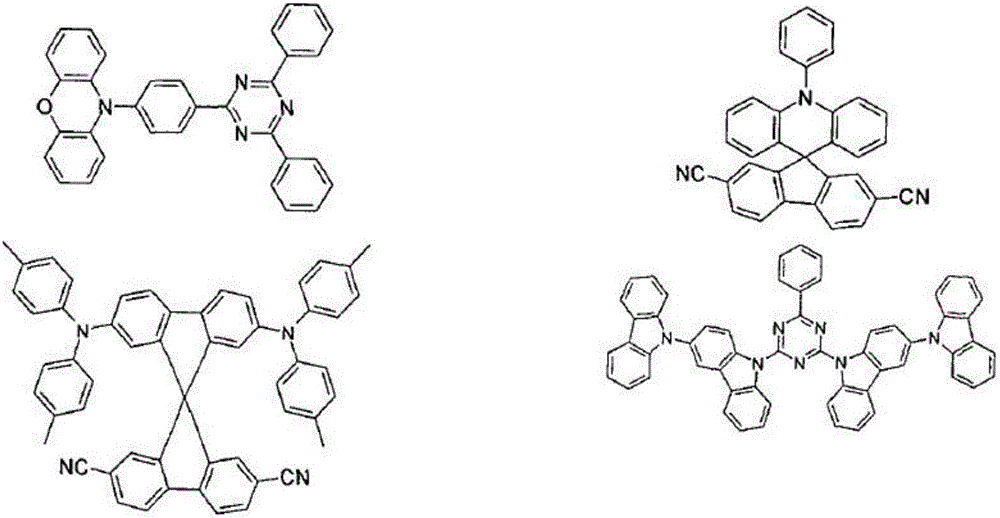

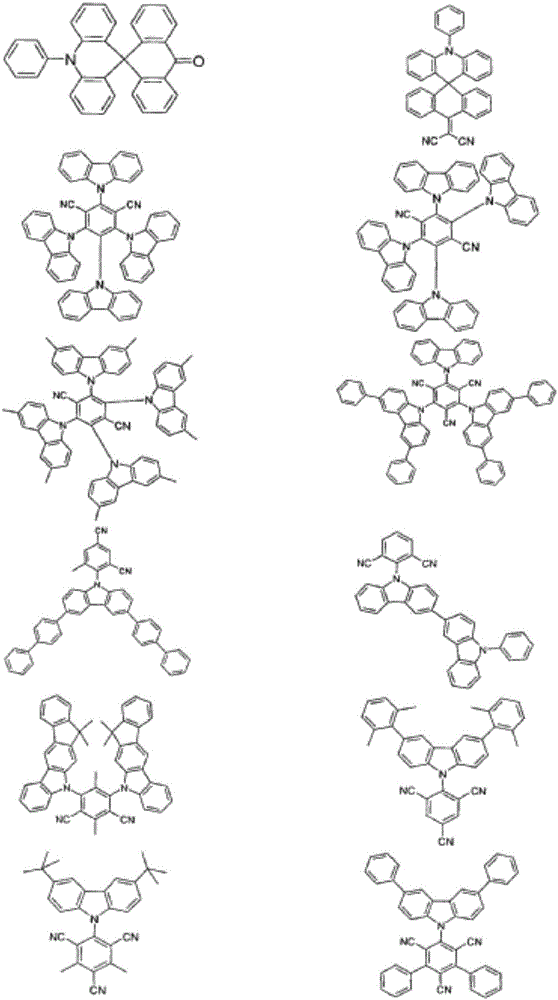

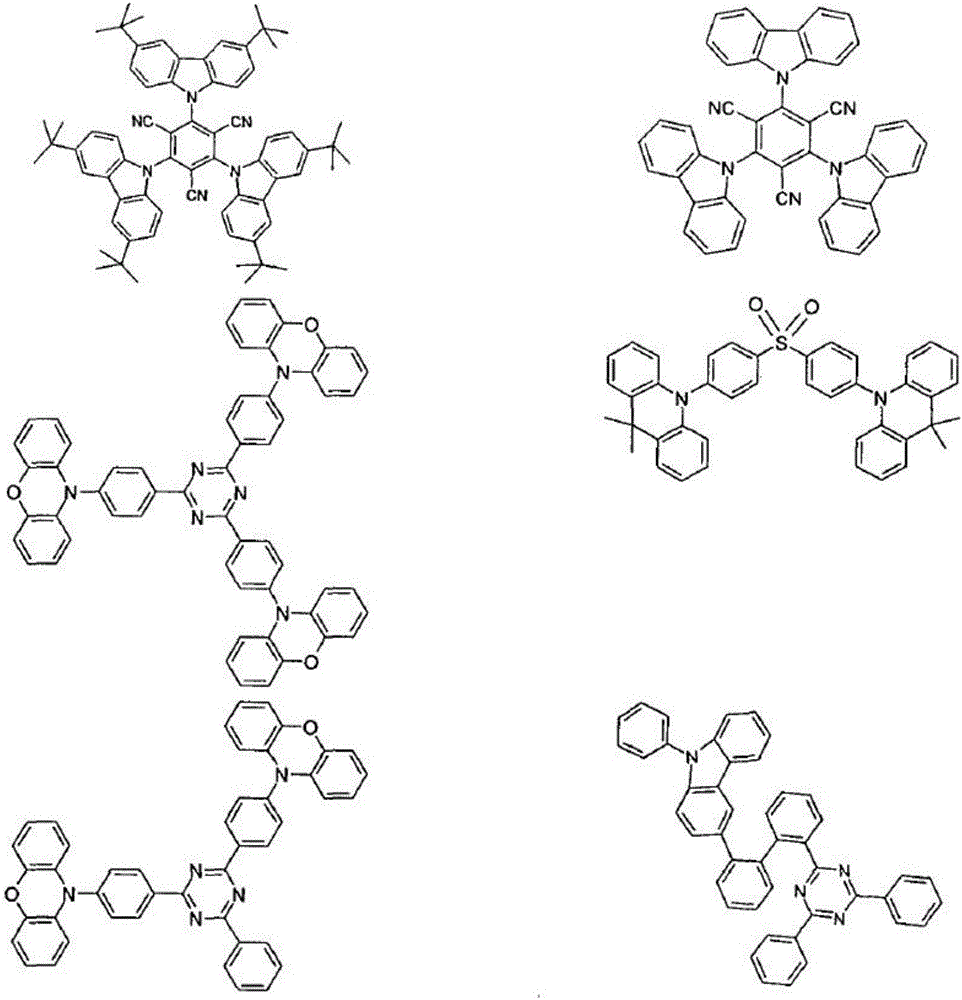

[0192] The materials required for the following examples are shown in Table 1. The attached HOMO and LUMO levels and the S 1 and T 1 Indicated in Table 2.

[0193] Vacuum Processed OLEDs

[0194] Wet cleaning (lab wash machine, Merck Extran cleaner) with a structured ITO (indium zinc oxide)-coated glass plate with a thickness of 50 nm followed by heating at 250 °C in a nitrogen atmosphere 15 minutes long and treated with oxygen plasma for 130s long before coating. A plasma-treated glass plate forms the substrate onto which the OLED is applied. The substrate is kept in vacuum prior to coating. Coating starts no later than 10 minutes after plasma treatment.

[0195] The material is thermally vapor deposited in a vacuum chamber. In this case, the emission layer is always composed of at least one host material (host material) and an emission material. A matrix material or matrix materials are mixed in specific volume fractions into the emission mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com