Control device and control method for variable valve mechanism

A valve mechanism and control device technology, applied in engine control, valve devices, mechanical equipment, etc., can solve problems such as hysteresis, and achieve the effects of suppressing fuel efficiency and running performance deterioration, over-regulation and response delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

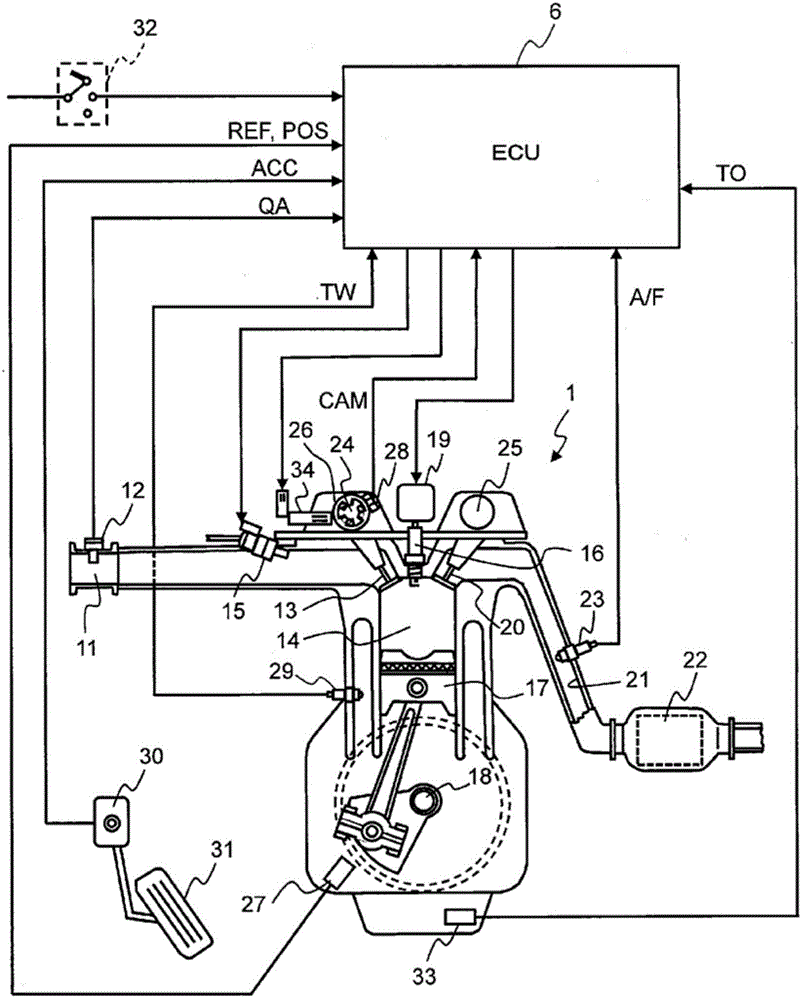

[0035] figure 1 It is a schematic configuration diagram of an engine to which the control method of the variable valve mechanism according to the embodiment of the present invention is applied.

[0036] The intake pipe 11 for introducing air into each cylinder of the engine (internal combustion engine) 1 is provided with an intake air amount sensor 12 that detects the intake air flow rate QA of the engine 1. As the intake air amount sensor 12, for example, a hot wire type flow meter that detects the mass flow rate of intake air or the like can be used.

[0037] The intake valve 13 opens and closes the intake port of the combustion chamber 14 of each cylinder, and in the intake pipe 11 on the upstream side of the intake valve 13, a fuel injection valve 15 is provided for each cylinder. The fuel injected by the fuel injection valve 15 is sucked into the combustion chamber 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com