A split type laminar flow constant interface pool and extraction method

A constant interface, split technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of inability to achieve mixing and drainage, leakage and mutual contact, poor applicability, etc., to ensure interface stability and eliminate diffusion. Influence, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

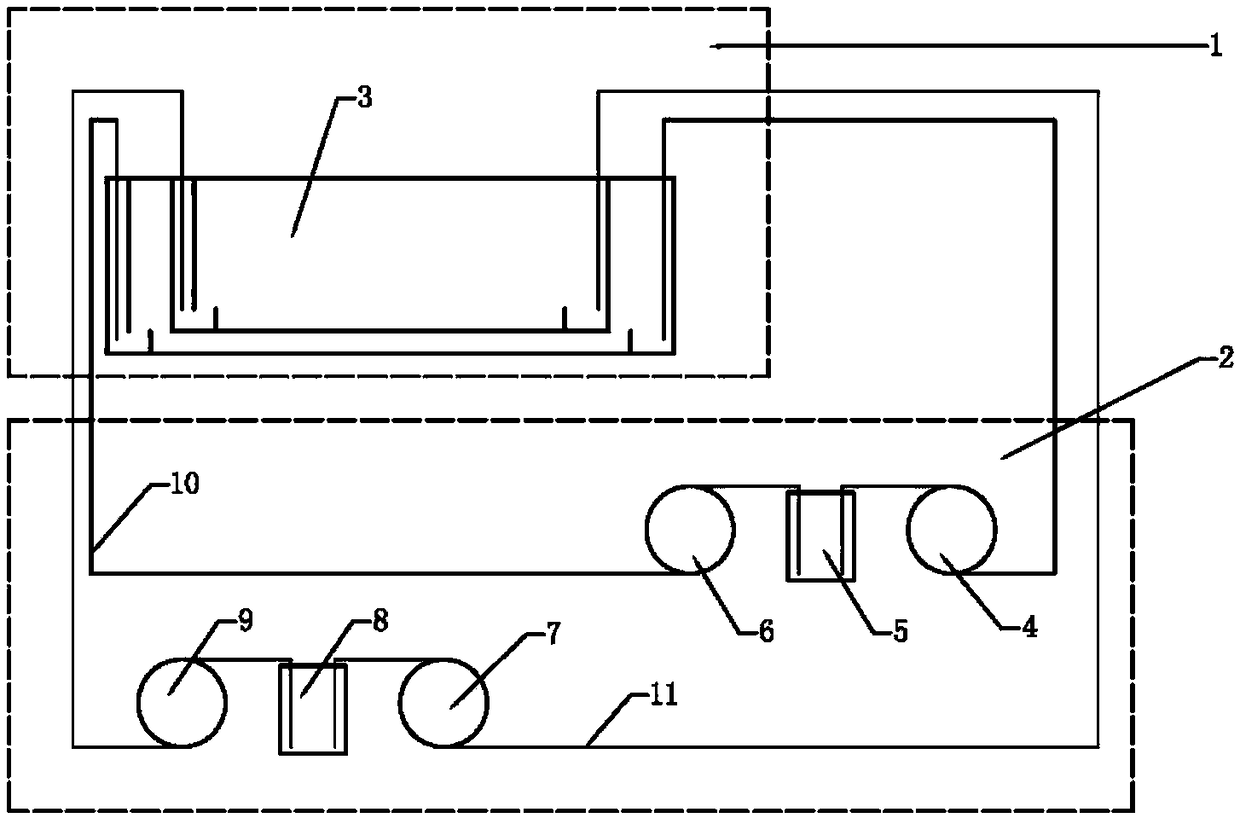

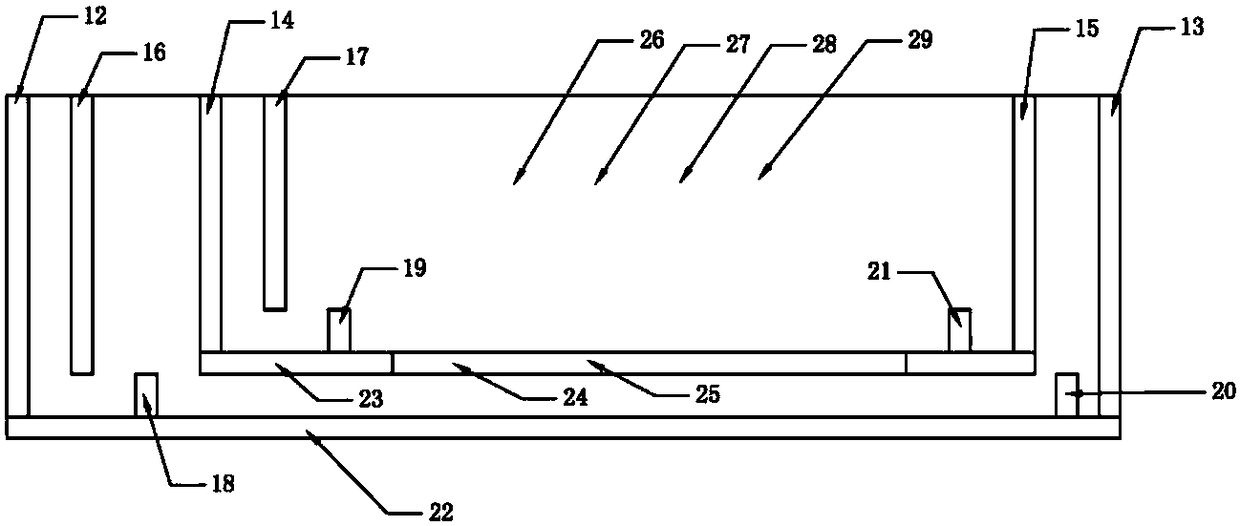

[0084] A kind of split type laminar flow constant interface pool 3 (such as Figure 1-Figure 4 shown), including laminar flow constant interface tank main body 1 and auxiliary system 2;

[0085] The main body 1 of the laminar flow constant interface tank includes a heavy phase liquid tank for placing the heavy phase and a light phase liquid tank for placing the light phase; the bottom plate of the light phase liquid tank is provided with a first through hole 24, and the heavy phase and the light phase pass through The first through hole 24 realizes laminar constant interface extraction;

[0086] The auxiliary system 2 includes a heavy phase auxiliary system and a light phase auxiliary system, the heavy phase auxiliary system is connected with the heavy phase liquid tank, and is used to input the mixed heavy phase into the heavy phase liquid tank, and extract the heavy phase after the extraction reaction takes place. The heavy phase is extracted; the light phase auxiliary syst...

Embodiment 2

[0099] A split type laminar flow constant interface pool 3, the structure of the split type laminar flow constant interface pool 3 is the same as that of the split type laminar flow constant interface pool 3 described in Example 1, the difference lies in:

[0100] The light phase liquid level stabilizing plate 17 of described light phase liquid tank is positioned at the right side of light phase liquid tank, and described heavy phase liquid level stabilizing plate 16 is positioned at the left side of heavy phase liquid tank (as Figure 5 b).

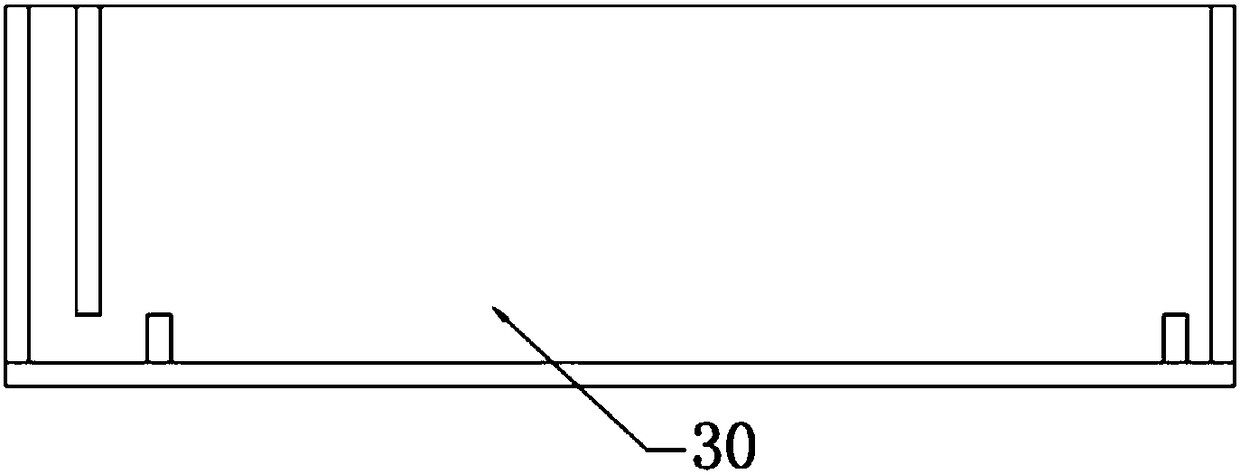

[0101] According to the different sizes of the light phase liquid tank and the heavy phase liquid tank, the size of the first through hole can be different from Figure 9 , the size of the interface plate and the size of the second through hole can also be different from the Figure 10 . Can be designed according to actual needs.

Embodiment 3

[0103] Using the split type laminar flow constant interface pool 3 described in embodiment 1, according to figure 1 Build a split laminar flow constant interface pool. The kinetic determination test of trivalent erbium in the P507-kerosene extraction hydrochloric acid system was carried out in the main body 1 of the laminar flow constant interface tank. The erbium ion hydrochloric acid solution with pH=3.0 was used as the water phase, and the 1.52mol / L P507-kerosene solution was used as the oil phase. The specification of the interface board used in the experiment is 70mm×140mm, and the specification of the second through hole on the interface board is 50mm×30mm, such as Figure 10 shown in d. Use the heavy phase extraction pump 4 to extract the water phase into the heavy phase mixing chamber 5 with a 500mL beaker. After the water phase is stirred, the heavy phase injection pump 6 injects the water phase into the front end of the heavy phase liquid tank of the laminar flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com