Pretreatment method and device for improving washing and desorption performance of soil

A pretreatment device and pretreatment technology, applied in the field of ex-situ remediation of polluted soil, can solve the problem of high particle size requirements, achieve high controllability, wide application range, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

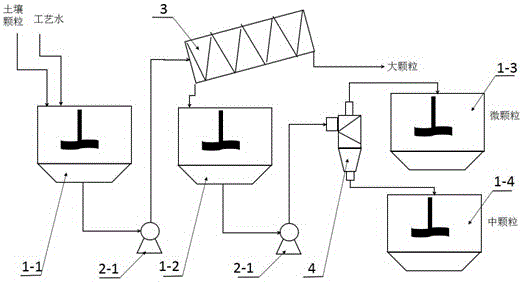

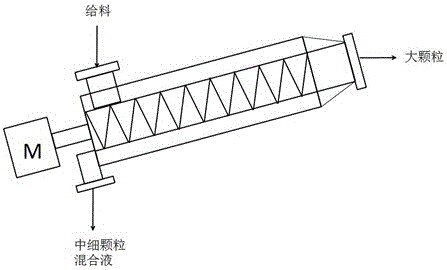

[0036] After extensive and in-depth research, the inventors of the present application found that the most effective and cheap method for washing polluted soil, which is a solid-liquid system with a large amount of treatment and is difficult to handle, is to use cyclone washing. In engineering, it is often necessary to pretreat the raw materials entering the cyclone washing and desorption treatment system, so as to reduce the operation volume and cost of the cyclone washing and desorption treatment. The jacketed screw feeding screen is inclined at a certain angle, and the large particles are not only transported but also screened through the action of the screw in the cylinder. jar, set aside for disposal. The hydrocyclone uses centrifugal force to achieve the separation of particles of different particle sizes, the tiny particles are discharged from the overflow port, and the medium particles are discharged from the bottom flow port. Through the function of these two main eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com