Protective gas preheating method and device for 3D printing

A technology of protective gas and preheating device, which is applied in the direction of improvement of process efficiency, improvement of energy efficiency, additive manufacturing, etc., can solve the problems affecting the shape accuracy and dimensional accuracy of parts, damage to flexible plastering, warping of processing layers, etc., to achieve Achieve real-time change, temperature stability, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

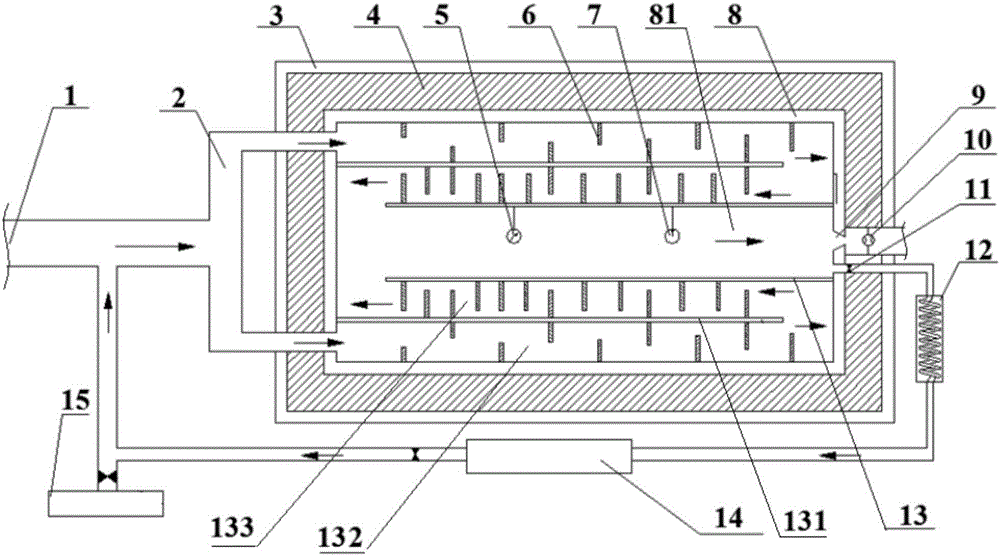

[0035] like figure 1 shown. The invention discloses a protective gas preheating device for 3D printing, which includes a protective cover 3, a vacuum preheating chamber 81 arranged in the protective cover 3, and an air inlet 1 respectively arranged at one end of the vacuum preheating chamber 81 and the gas outlet 9 at the other end; the vacuum preheating chamber 81 is provided with two gas heating passages 13 with the same structure; the gas enters the gas heating passage 13 from the air inlet 1 and enters the vacuum preheating chamber 81 after being heated. Then enter the molding chamber through the air outlet 9. The gas generally refers to an inert gas.

[0036] In the gas heating channel 13, there are a plurality of electric heating columns 6 spaced apart from each other and arranged in an array; the axes of the electric heating columns 6 are perpendicular to the gas flow direction; the gas entering the gas heating channel 13 is heated by the electric heating columns 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com