Thrust current control module used for wireless electric welding machine

A current control module and radio technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high cost of use, reduction of electrode contact resistance, and impact on conversion efficiency, so as to improve welding quality and efficiency, improve The effect of outputting load current and improving the overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

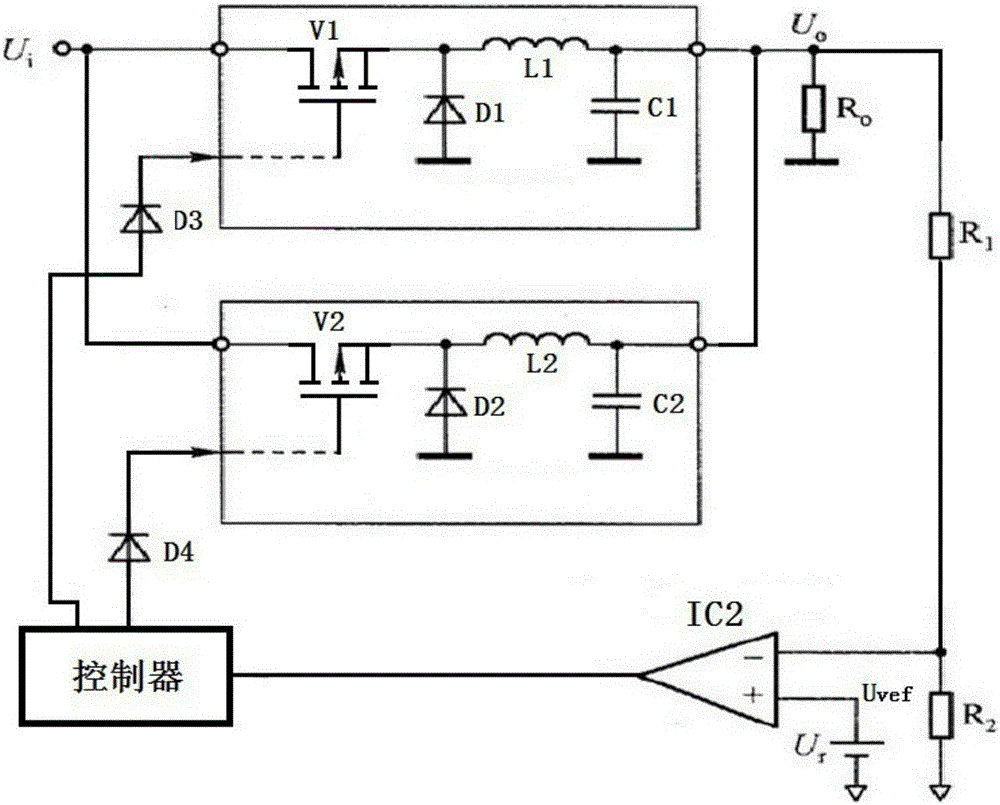

[0023] like figure 1 As shown, a thrust current control module for a wireless welding machine includes a battery unit, the battery unit is a battery pack composed of multiple lithium batteries connected in series and parallel, preferably a ternary lithium battery with a large discharge capacity. It includes a main control circuit, a voltage sampling circuit, and a controller. The main control circuit includes a first BUCK loop and a second BUCK loop. The first BUCK loop and the second BUCK loop are connected in parallel. The first BUCK loop includes a diode D3, a MOS Tube V1, diode D1, inductor L1, capacitor C1, the cathode of the diode D3 is connected to the gate of the MOS transistor V1, the source of the MOS transistor V1 is connected to the positive pole of the battery pack, the drain of the MOS transistor V1 is connected to the cathode of the diode D1, One end of the inductance L1 is connected, the other end of the inductance L1 is connected to one end of the capacitor C1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com