A quartz stone polishing device

A polishing device and quartz stone technology, which is applied to grinding drive devices, grinding/polishing equipment, machine tools for surface polishing, etc. Polishing degree, polishing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

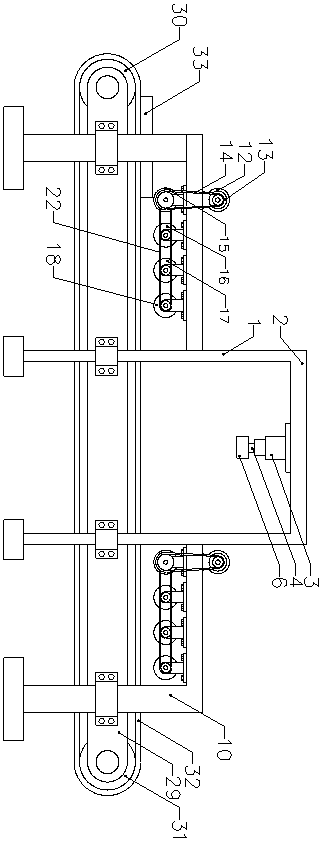

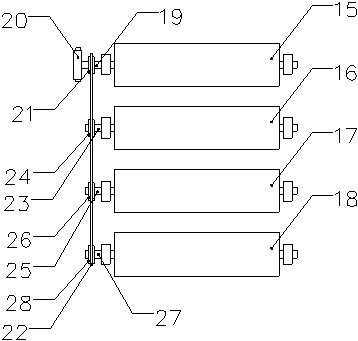

[0025] Such as Figure 1-6 As shown, a quartz stone polishing device includes a turning mechanism and polishing mechanisms arranged on both sides of the turning mechanism:

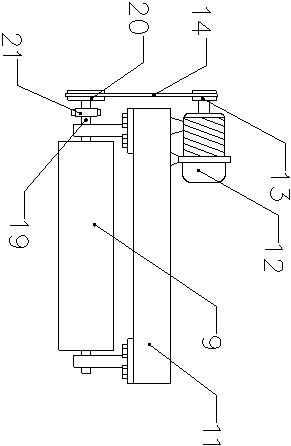

[0026] The overturning mechanism includes a leg A1 and a support plate A2 fixed on the leg A1, the lower side of the support plate A2 is fixed with a hydraulic cylinder 3 by bolts, and the hydraulic cylinder 3 is connected with a hydraulic telescopic rod 4 , the end of the hydraulic telescopic rod 4 is fixed with a two-way electric telescopic rod 5, and the two ends of the two-way electric telescopic rod 5 are fixed with clips 6; the lower side of the two-way electric telescopic rod 5 is equipped with an infrared sensor 7 , the right side of the infrared sensor 7 is equipped with a range finder 8, and the range finder 8 and the infrared sensor 7 are connected with a microcontroller 9 through a signal line;

[0027] The polishing mechanism includes a leg B10 and a support plate B11 fixed on the leg B10, a ...

Embodiment 2

[0038] Such as Figure 1-6 As shown, a quartz stone polishing device includes a turning mechanism and a polishing mechanism arranged on both sides of the turning mechanism; the turning mechanism includes a support leg A1 and a support plate A2 fixed on the support leg A1, and the support The lower side of the plate A2 is fixed with a hydraulic cylinder 3 by bolts, the hydraulic cylinder 3 is connected with a hydraulic telescopic rod 4, and the end of the hydraulic telescopic rod 4 is fixed with a two-way electric telescopic rod 5, and the two-way electric telescopic rod 5 The two ends of the rod 5 are fixed with clips 6; the lower side of the two-way electric telescopic rod 5 is equipped with an infrared sensor 7, and the right side of the infrared sensor 7 is equipped with a range finder 8, and the range finder 8 and the infrared sensor 7 are connected with a microcontroller 9 through a signal line; the polishing mechanism includes a support leg B10 and a support plate B11 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com