Soundproof wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and wood fiber materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. The effect of sound performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

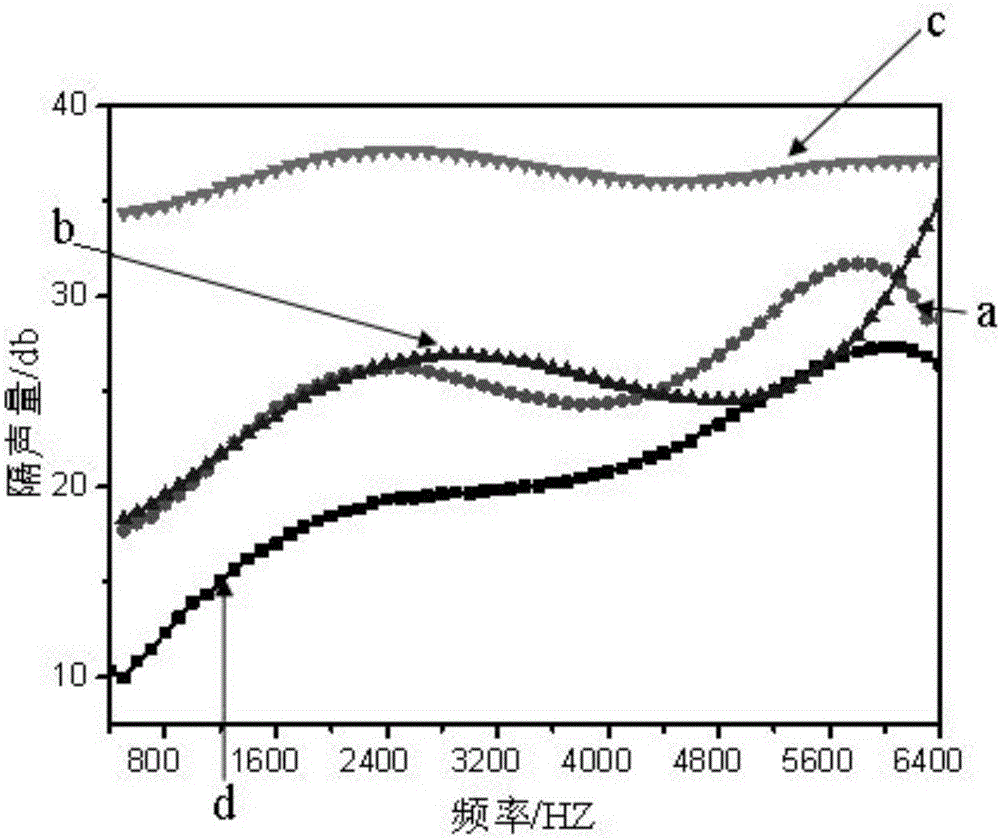

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1: In this embodiment, a sound-insulating wood-plastic composite material includes a core wood-plastic layer and surface wood veneer layers on both sides.

[0014] The sound-insulating wood-plastic composite material provided by this embodiment not only has good sound-insulating performance, but also has good thermal insulation, wooden decorative appearance, light weight and environmental protection.

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the core wood-plastic layer is composed of 30-50 parts by weight of thermoplastics, 50-80 parts of wood fiber materials, 1-5 parts Wood-plastic composite board made of coupling agent, 3-6 parts of lubricant and 0-10 parts of hollow glass microspheres. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the core wood-plastic layer consists of 40 parts by weight of thermoplastics, 60 parts of wood fiber materials, and 5 parts of coupling agent and 2 parts lubricant. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com