Inorganic binder stabilized soil as road subbase filling and production method of inorganic binder stabilized soil

An inorganic binder and soil stabilizing technology, applied in roads, roads, buildings, etc., can solve problems such as soil calcification, achieve the effects of reducing project cost, saving resources, and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment is prepared as the inorganic binder stabilized soil of the road sub-base filler according to the following steps:

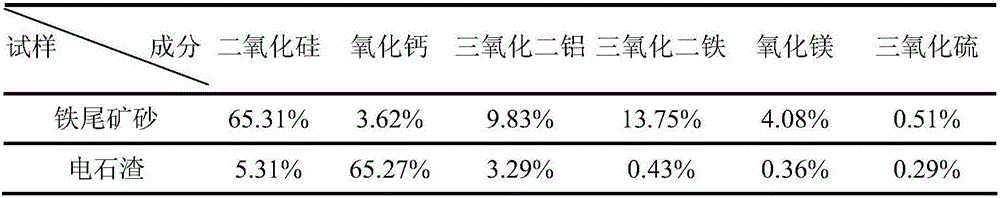

[0038] The first step is to take 50kg of representative soil samples with natural moisture content, crush them and pass through a 20mm sieve, mix the soil samples under the sieve evenly, and measure the natural moisture content of the soil samples; weigh 6% carbide slag according to the mass percentage , 20% iron tailings sand and 74% dried soil; first fully mix the iron tailings sand and dried soil sample, and then stir evenly with calcium carbide slag to obtain mixed soil;

[0039] In the second step, the optimal water content of the mixed soil is determined to be 11.9% according to the heavy compaction test in the "Highway Soil Test Regulations" (JTG E40-2007);

[0040] In the third step, according to the optimal water content determined in the second step, adjust the water content of the mixed soil obtained in the first step so a...

Embodiment 2

[0044] The present embodiment is prepared as the inorganic binder stabilized soil of the road sub-base filler according to the following steps:

[0045] The first step is to take 50kg of representative soil samples with natural moisture content, crush them and pass through a 20mm sieve, mix the soil samples under the sieve evenly, and measure the natural moisture content of the soil samples; weigh 8% carbide slag according to the mass percentage , 20% iron tailings and 72% dried soil, fully mix the iron tailings and dried soil samples first, and then stir with calcium carbide slag evenly to obtain mixed soil;

[0046] The second step is to determine the optimal moisture content of the mixed soil to be 13.8% according to the heavy compaction test in the "Highway Soil Test Regulations" (JTG E40-2007);

[0047] In the third step, according to the optimal moisture content determined in the second step, adjust the moisture content of the mixed soil obtained in the first step to kee...

Embodiment 3

[0051] The present embodiment is prepared as the inorganic binder stabilized soil of the road sub-base filler according to the following steps:

[0052] The first step is to take 50kg of representative soil samples with natural moisture content, crush them and pass through a 20mm sieve, mix the soil samples under the sieve evenly, and measure the natural moisture content of the soil samples; weigh 6% carbide slag according to the mass percentage , 30% iron tailings sand and 64% dried soil, the iron tailings sand and dried soil sample are fully mixed first, and then mixed with calcium carbide slag evenly to obtain mixed soil;

[0053] The second step is to determine the optimum moisture content of the mixed soil to be 14.0% according to the heavy compaction test in the "Highway Soil Test Regulations" (JTG E40-2007);

[0054] In the third step, according to the optimal moisture content determined in the second step, adjust the moisture content of the mixed soil obtained in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com