Direct-vat type environment-friendly anti-rutting agent and production device and method thereof

An anti-rutting agent and environmentally friendly technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of unrealistic, segregation of modifier and matrix asphalt, energy consumption, etc., to achieve convenient use and improve anti-rutting performance. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

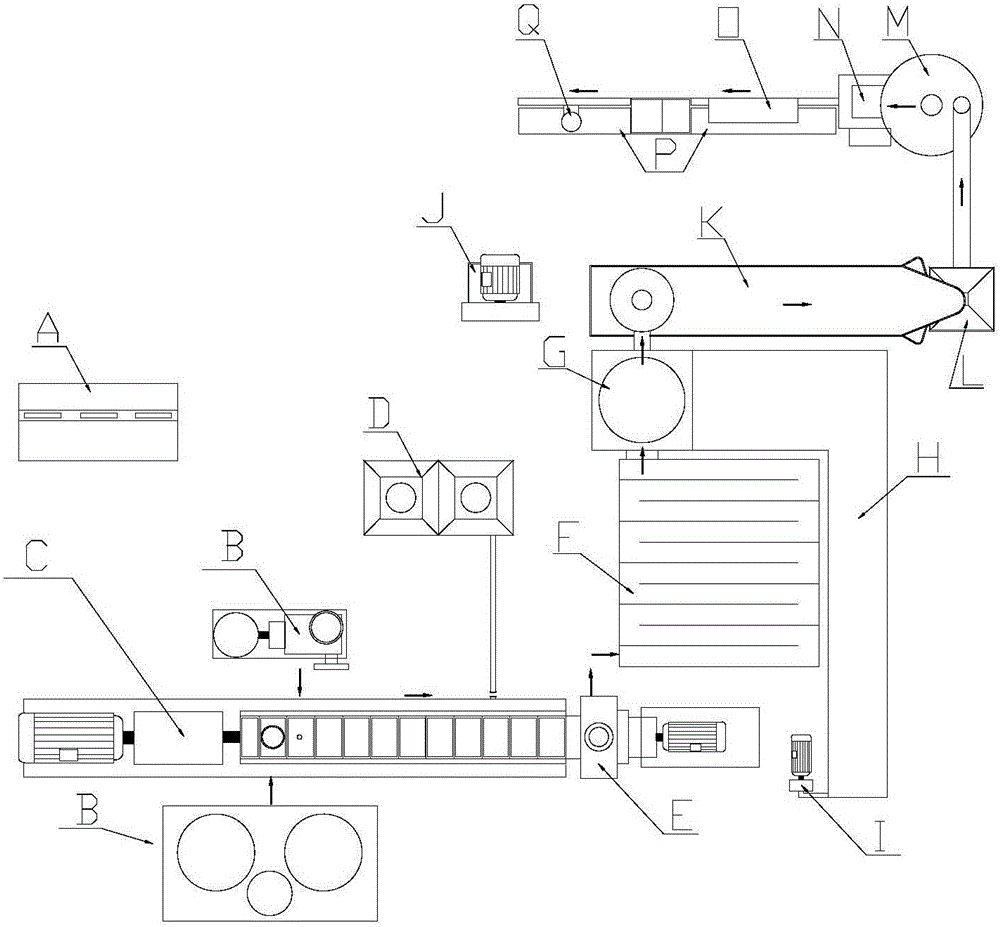

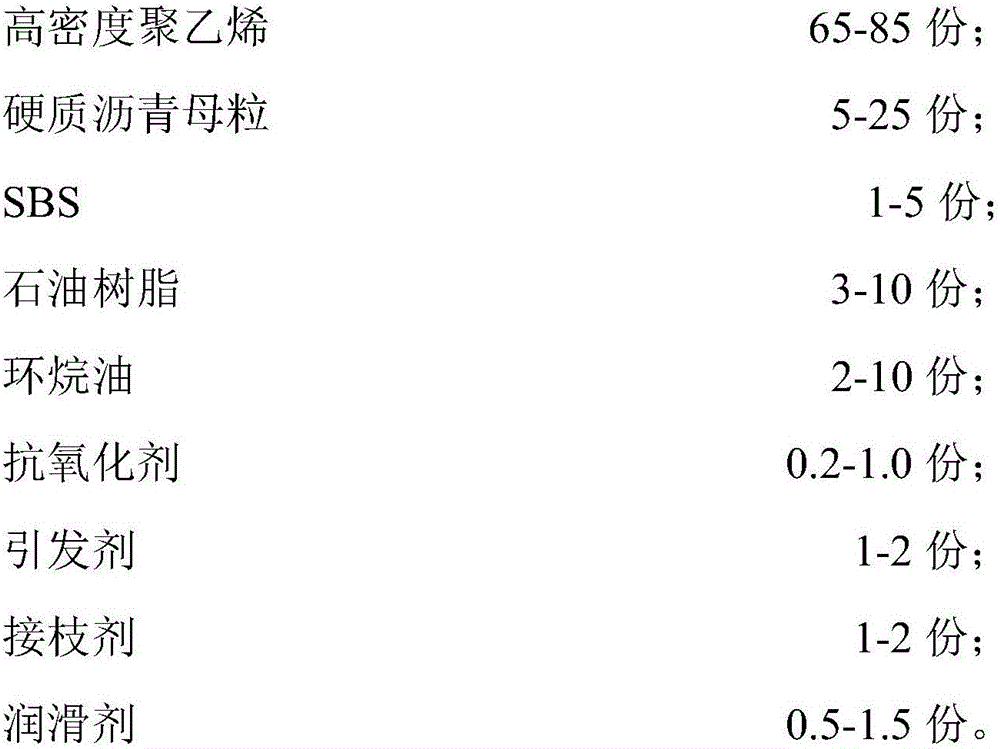

[0045]68 parts of high-density polyethylene fragments; 14 parts of hard asphalt masterbatch; 1 part of SBS; 7 parts of C9 petroleum resin; 6 parts of naphthenic oil KN4010; 1 part of antioxidant 164; 1 part of azobisisobutyronitrile; 1 part of maleic anhydride grafting agent 108-31-6; 1 part of polyethylene wax H1001 is added into the mixing type twin-screw extruder through the automatic batching system, and the mixing type twin-screw extruder is preheated to 190 ° C to make The material is evenly mixed, melted, kneaded, modified, and extruded through the die; the water circulation pelletizer connected with the die cuts the freshly extruded material into 3mm-long pieces under the high-speed rotating cutter. Ellipsoidal particles; the exhaust gas collection and treatment device collects and treats the waste gas generated during the production process; the circulating water pump pressurizes the circulating water in the circulating water tank to 0.5MPa / cm 2 Finally, it is sent to...

Embodiment 2

[0047] Components according to the following parts by weight: 76 parts of high-density polyethylene fragments; 9 parts of hard asphalt masterbatch; 3 parts of SBS; 5 parts of C5 petroleum resin; 2 parts of naphthenic oil KN4010; 1 part of antioxidant 164; 1 part Benzoyl peroxide; 2 parts of maleic anhydride grafting agent 108-31-6; 1 part of polyethylene wax H1001, according to the preparation method of Example 1, made into granular anti-rutting agent.

Embodiment 3

[0049] Components according to the following parts by weight: 81 parts of high-density polyethylene fragments; 5 parts of hard asphalt masterbatch; 5 parts of SBS; 3 parts of C9 petroleum resin; 1 part of naphthenic oil KN4010; 1 part of antioxidant 164; 1 part Azobisisobutyronitrile; 1 part of maleic anhydride grafting agent 108-31-6; 1 part of polyethylene wax H1001. According to the preparation method of Example 1, a granular anti-rutting agent was made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com