Conductive coating material containing physical stripping graphene and preparation method of coating material

A conductive coating and physical peeling technology, which is applied in the direction of conductive paint, coating, epoxy resin coating, etc., can solve the problem of difficult physical peeling of graphene dispersion, poor dispersion of physical peeling graphene, and difficulty in preparing water-based conductive coatings. Layer materials and other issues, to achieve the effect of less structural defects, excellent electrical conductivity, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

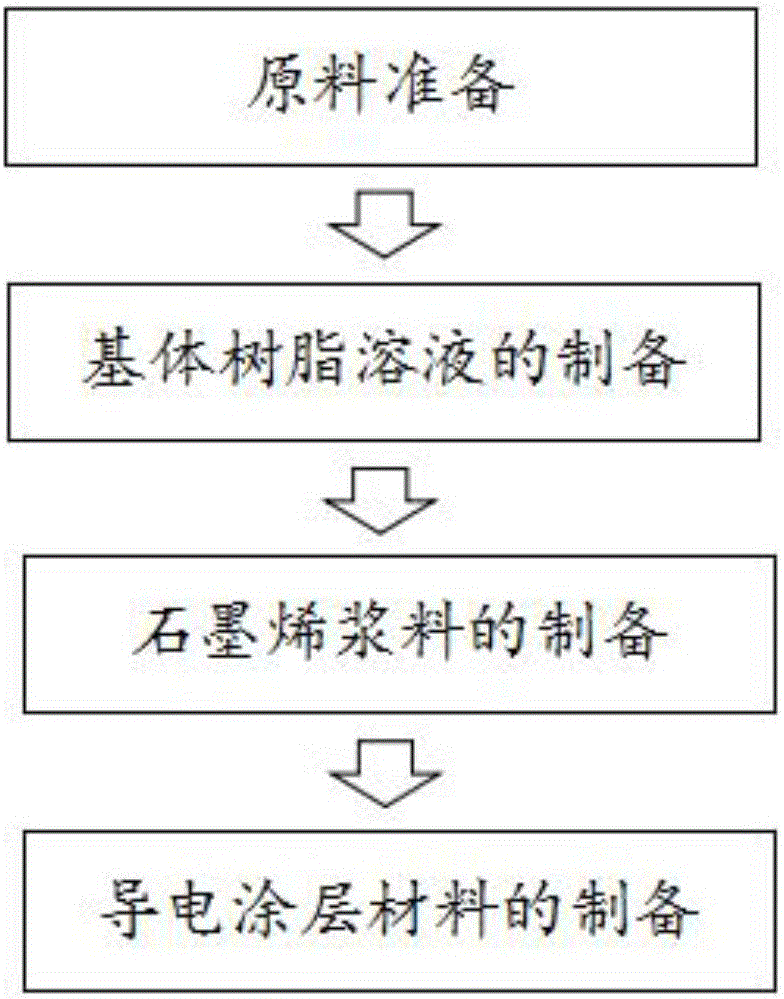

Method used

Image

Examples

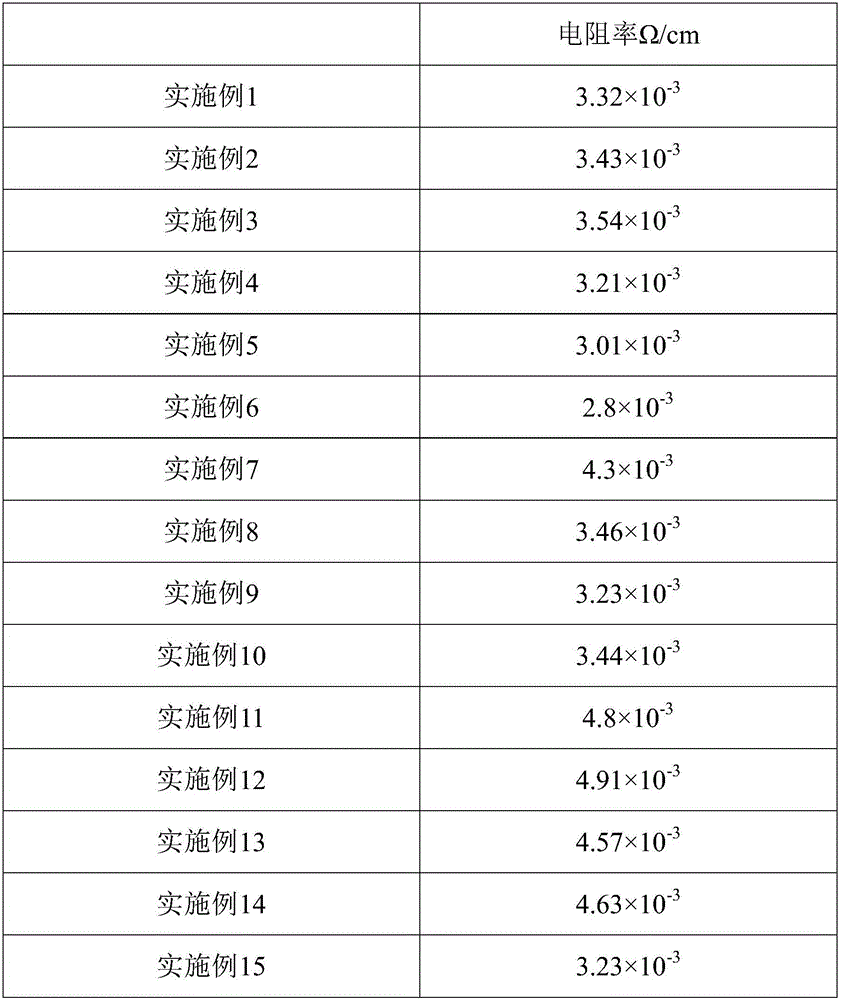

Embodiment 1

[0031] 9 parts of polyvinylpyrrolidone were weighed and dissolved in 30 parts of N-methylpyrrolidone to obtain a polyvinylpyrrolidone solution. Take 9 parts of 50-mesh physically exfoliated graphene powder and add it to 40 parts of N-methylpyrrolidone, ultrasonicate for 2 hours, ultrasonic power is 500W and ultrasonic temperature is 30°C to obtain graphene slurry. Mix the polyvinylpyrrolidone solution with the graphene slurry obtained after ultrasonication and add 3 parts of dispersant (BYK161), 3 parts of leveling agent (BYK361), 3 parts of defoamer (BYK088), 3 parts of coupling agent ( KH550) high-speed disperser for dispersing, the dispersing speed is 2000r / min, and the dispersing time is 30min. The resistivity of the prepared conductive coating material is shown in Table 1.

Embodiment 2

[0033] Weigh 9 parts of polyvinylpyrrolidone and dissolve in 30 parts of dioxane. Take 9 parts of 50-mesh high-quality physically exfoliated graphene powder and add 40 parts of dioxane to ultrasonic for 2 hours, with ultrasonic power of 400W and ultrasonic temperature of 30°C. Mix the polyvinylpyrrolidone solution with the graphene slurry after ultrasonication and add 3 parts of dispersant (BYK110), 3 parts of leveling agent (BYK356), 3 parts of defoamer (BYK057), 3 parts of coupling agent (KH560 ) High-speed dispersing machine for dispersing, the dispersing speed is 1000r / min, and the dispersing time is 60min. The resistivity of the prepared conductive coating material is shown in Table 1.

Embodiment 3

[0035]Weigh 17 parts of polyvinylpyrrolidone and dissolve in 30 parts of N,N-dimethylformamide. Take 1 part of 50-mesh high-quality physically exfoliated graphene powder and add 40 parts of N,N-dimethylformamide to ultrasonic for 4 hours, ultrasonic power 500W, ultrasonic temperature 30°C. Mix the polyvinylpyrrolidone solution with the graphene slurry after ultrasonication and add 3 parts of dispersant (BYK168), 3 parts of leveling agent (BYK399), 3 parts of defoamer (BYK052), 3 parts of coupling agent (KH560 ) High-speed dispersing machine for dispersing, the dispersing speed is 2000r / min, and the dispersing time is 50min. The resistivity of the prepared conductive coating material is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com