Continuous reaction system for preparing bio-oil through microalgae hydrothermal liquidization and method thereof

A technology of hydrothermal liquefaction and reaction system, which is applied in the preparation of liquid hydrocarbon mixture, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of high overall energy consumption of the system and continuous operation of the system, and achieve complete product separation and system continuity. Good, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

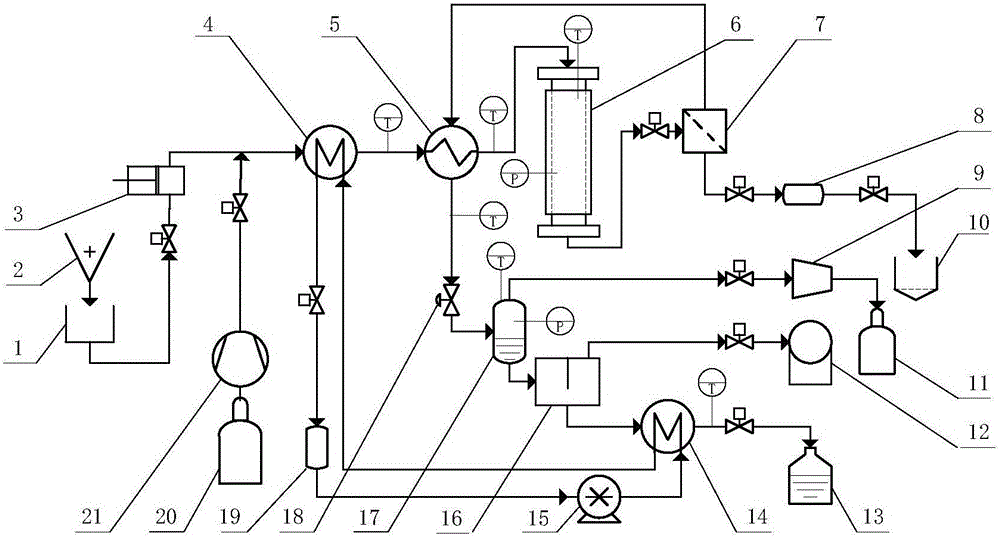

[0021] The invention discloses a continuous reaction system for preparing bio-oil by hydrothermal liquefaction of microalgae. By setting two-stage preheaters, the waste heat after liquefaction reaction can be fully utilized, thereby reducing the overall energy consumption of the reaction system. In addition, the system can continuously and efficiently realize the separation of liquefied products through the joint action of solid-liquid separator, gas-liquid separator and centrifuge, without the need for additional organic solvents to separate bio-oil. Compared with other hydrothermal liquefaction systems, the system of the present invention has low operating cost, thorough product separation and good system continuity, and can be widely used in microalgae hydrothermal liquefaction to produce bio-oil.

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com