Environment-friendly heavy-duty gear lubricant prepared from NPE (neopentyl polyol ester) with addition of hexadecyl calcium borate

A technology of calcium cetyl borate and polyol ester, which is applied in the field of lubricating oil, can solve problems such as inconvenient use, and achieve the effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

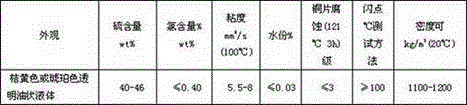

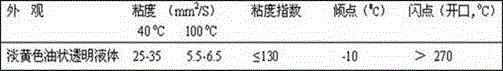

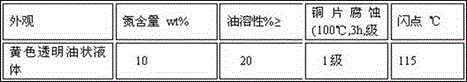

[0021] Lubricating oil with cetyl calcium borate added to neopentyl polyol ester (NPE-3), adding neopentyl polyol ester to neopentyl polyol ester (NPE-3) oil: lubricating oil additive formula selection : Calcium hexadecyl borate (T362): 0.96%, dihydrocarbyl pentasulfide: Rc2540: 0.36%, phosphorus star 0.10%, isobutylene sulfur (T321) 0.20%, benzotriazole fatty amine salt T406E: 0.45%, Stir evenly and heat at 80°C for 40 minutes to obtain.

Embodiment 2

[0023] The lubricating oil with cetyl calcium borate added to neopentyl polyol ester (NPE-3) is added with neopentyl polyol ester (NPE-3) base oil in neopentyl polyol ester weight percent: containing ten Hexaalkyl borate calcium (T362): 0.6%, dihydrocarbyl pentasulfide: Rc2540: 0.42%, phosphorus star 0.15%, sulfurized isobutylene (T321) 0.10%, benzotriazole fatty amine salt T406E: 0.09%, mix and stir After uniformity, heat at 80°C for 40 minutes to obtain.

Embodiment 3

[0025] The lubricating oil with cetyl calcium borate added to neopentyl polyol ester (NPE-3) is added with neopentyl polyol ester (NPE-3) base oil in neopentyl polyol ester weight percent: containing ten Hexaalkyl borate calcium (T362): 0.72%, dihydrocarbyl pentasulfide: Rc2540: 0.24%, phosphorus star 0.30%, sulfurized isobutylene (T321) 0.30%, benzotriazole fatty amine salt T406E: 0.63%, mixed and stirred After uniformity, heat at 80°C for 40 minutes to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com