Compound high modulus asphalt concrete bridge deck structure and arrangement method

An asphalt concrete, high-modulus technology, used in bridge construction, bridges, bridge parts, etc., can solve the problems affecting the durability of double-layer SMA asphalt concrete structures, insufficient cohesion, shearing, and difficulty in compaction and water seepage coefficient. meet design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

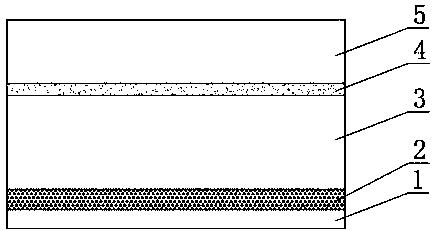

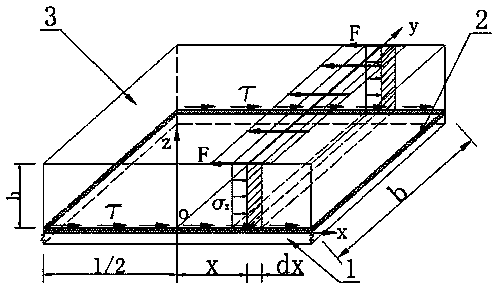

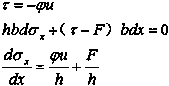

[0086] Such as Figure 1~Figure 2 As shown, 1. Cement concrete bridge deck, 2. Waterproof adhesive layer, 3. Composite high modulus asphalt concrete, 4. Emulsified asphalt adhesive layer, 5. Wear layer.

[0087] A composite high modulus bridge deck asphalt concrete structure, such as figure 1 As shown, it mainly includes pouring cement concrete bridge deck 1 on the main structure of the bridge. Junction layer 4, wearing layer 5.

[0088] The cement concrete bridge deck 1 is a structural layer set on the main structure of the bridge to protect the main structure of the bridge. Its surface is treated by shot blasting to clean up the laitance, impurities and roughening on the surface of the layer to make the surface uniform. The rough surface can improve the bonding strength between the waterproof bonding layer 2 and the cement concrete bridge deck 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com