Multi-stage tempering process of automobile leaf spring

A technology for leaf springs and automotive steel plates, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems such as the inability to digitally monitor the tempering process, the inability to accurately control the temperature curve, and the inability to obtain material organization and properties. The effect of reducing labor consumption, good practical performance and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

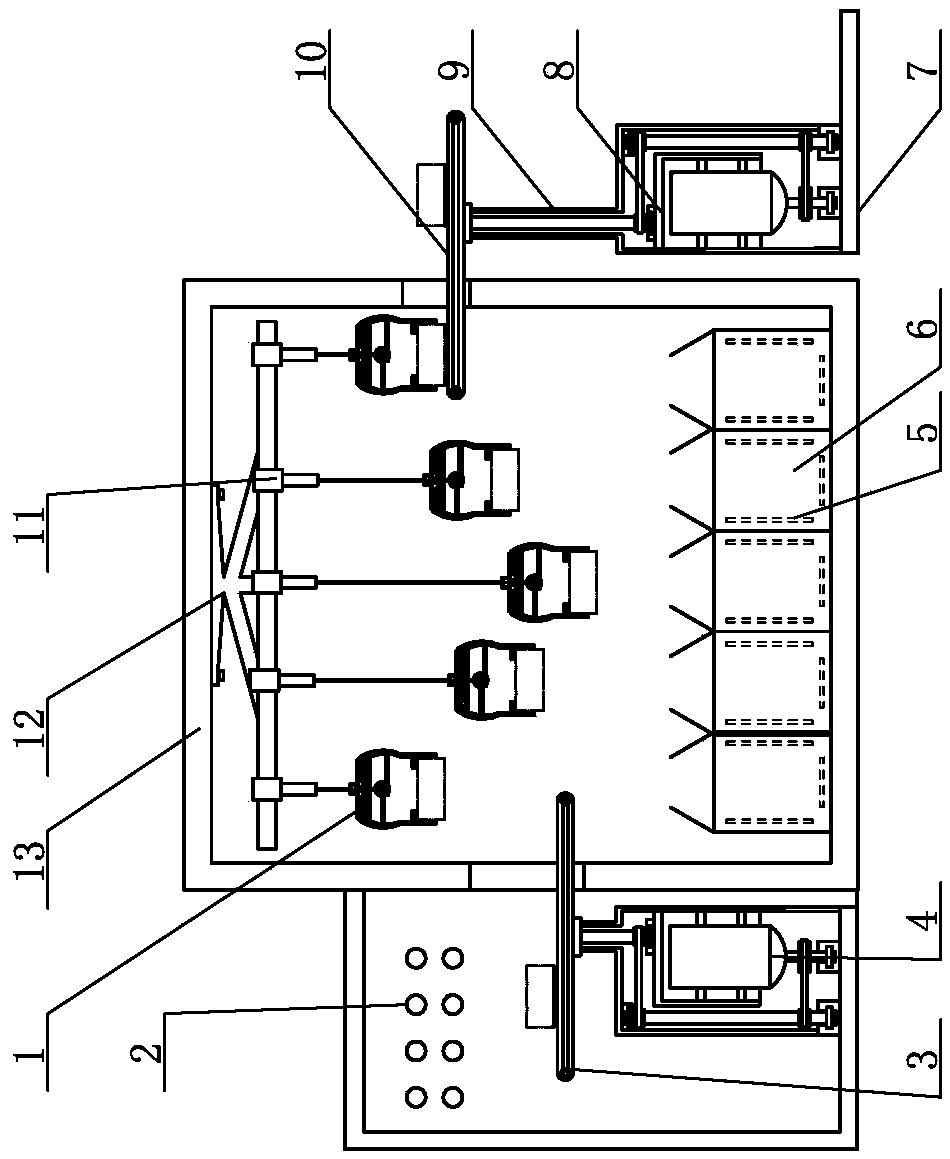

[0035] The multi-stage tempering process of automobile leaf spring of the present invention includes the following steps:

[0036] (1) Place the leaf spring on the feed conveyor belt and transport it to the tempering box;

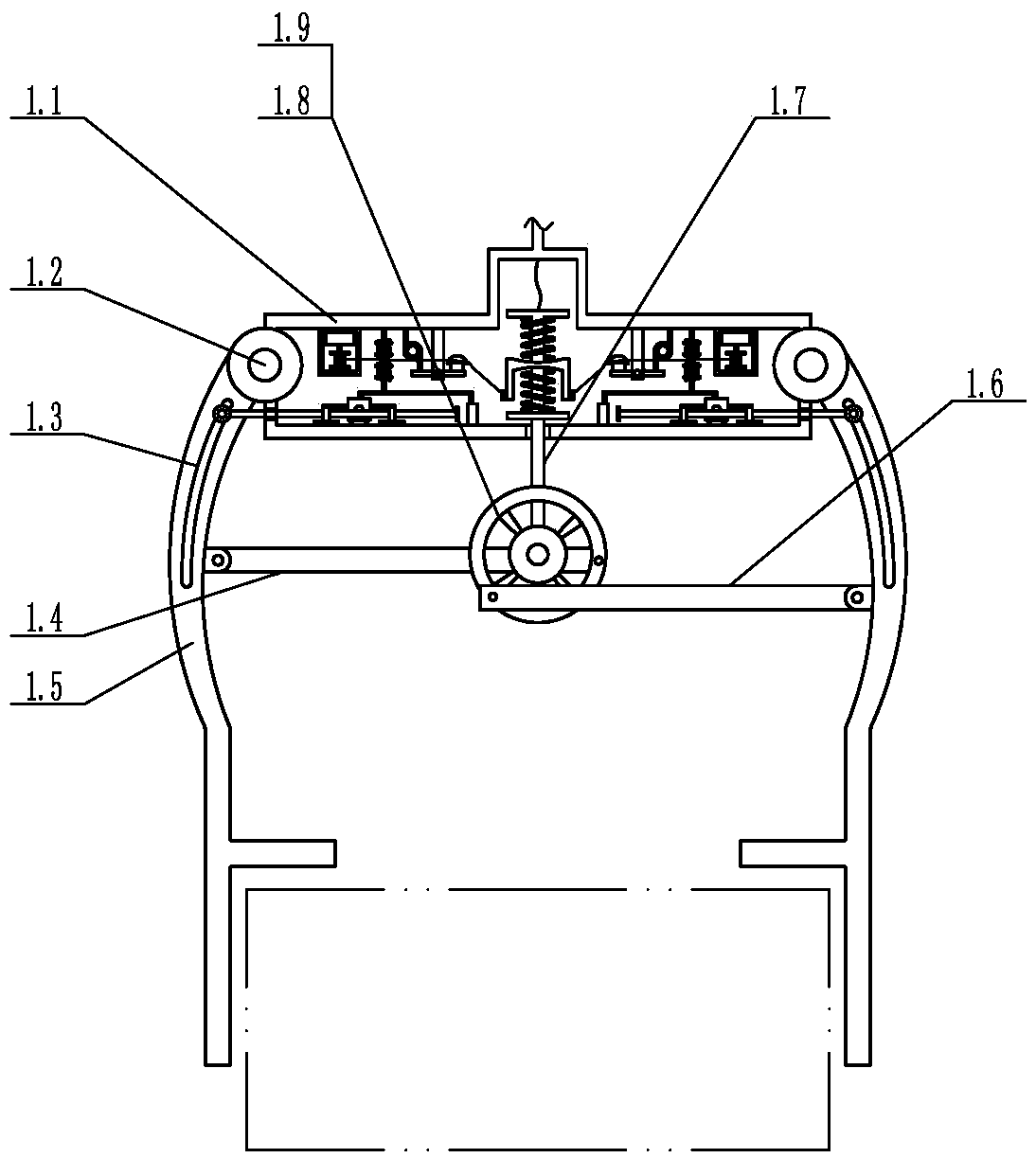

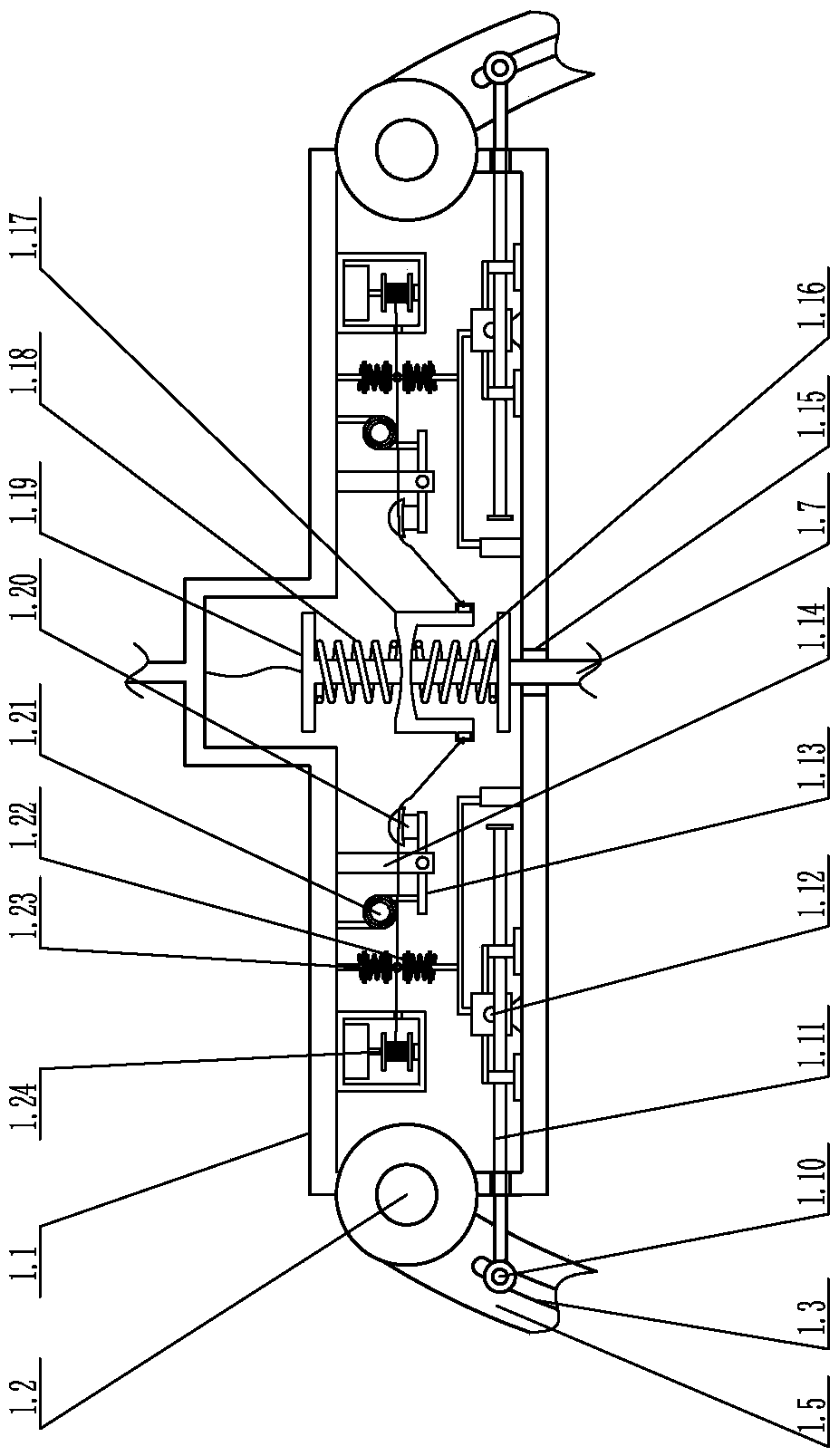

[0037] (2) The manipulator clamps the leaf spring and places it in the corresponding tempering furnace for heating, and heating to below the critical temperature for heat preservation;

[0038] (3) The manipulator clamps the tempered leaf spring out of the tempering furnace;

[0039] (4) The surface temperature of the leaf spring is detected by the infrared thermometer on the manipulator. After reaching the preset heating temperature, the manipulator places the leaf spring on the discharge conveyor belt, and conveys the leaf spring to cooling through the discharge conveyor belt. In the warehouse, adjust the air temperature and flow rate in the cooling warehouse, so that the leaf spring is cooled according to different speed curves according to the process design of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com