Nb-Hf-Zr-TiO2 alloy bar and preparation method thereof

A technology of nb-hf-zr-tio2 and alloy rods, applied in the field of Nb-Hf-Zr-TiO2 alloy rods and its preparation, can solve problems such as limited prospects, achieve improved room temperature plasticity, high temperature mechanical properties, Effect of Good Room Temperature Plasticity and Tensile Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

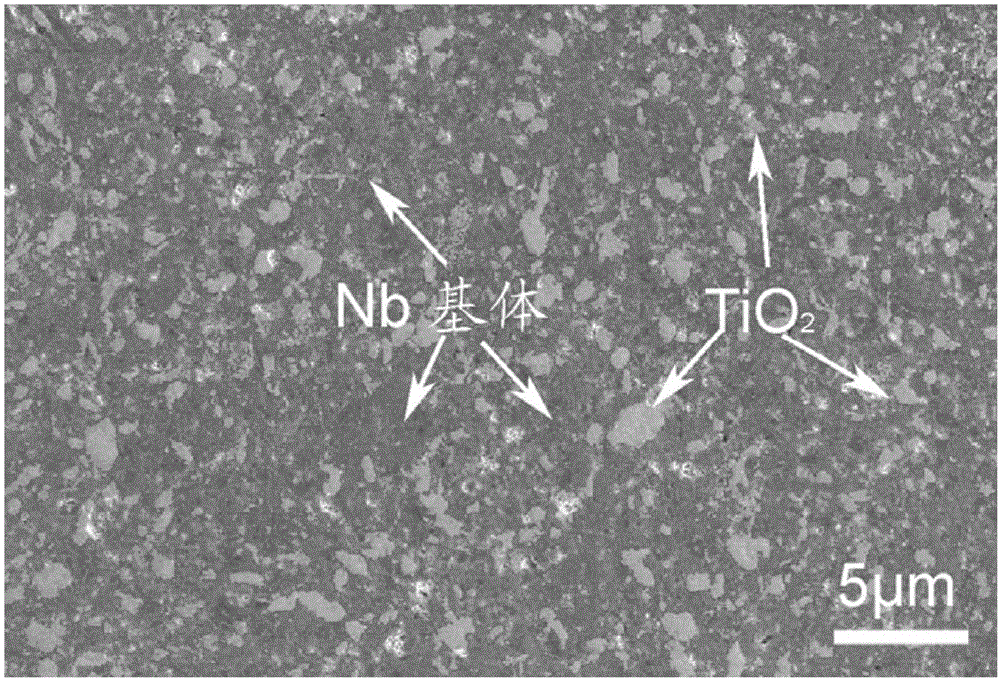

Image

Examples

Embodiment 1

[0025] In this example Nb-Hf-Zr-TiO 2 Alloy rods are made of raw materials with the following mass percentages: Hf 5%, Zr 5%, TiO 2 7%, the balance being Nb.

[0026] This example prepares Nb-Hf-Zr-TiO 2 The method for alloy rods comprises the steps of:

[0027] Step 1. Place niobium powder, hafnium powder, zirconium powder and titanium dioxide powder in a ball mill, and ball mill and mix them evenly under the protection of an argon atmosphere to obtain a mixed powder; the ball mill speed of the ball mill is 250r / min, and the ball mill The time for ball milling is 15 hours; the particle size of the hafnium powder and zirconium powder is not greater than 10 μm, the particle size of the titanium dioxide powder is not greater than 5 μm, and the particle size of the niobium powder is not greater than 20 μm; the hafnium powder, zirconium powder and titanium dioxide powder The mass purity of the niobium powder is not less than 99.5%, and the mass purity of the niobium powder is ...

Embodiment 2

[0035] In this example Nb-Hf-Zr-TiO 2 Alloy rods are made of raw materials with the following mass percentages: Hf 2%, Zr3%, TiO 2 4%, the balance being Nb.

[0036] This example prepares Nb-Hf-Zr-TiO 2 The method for alloy rods comprises the steps of:

[0037] Step 1. Put niobium powder, hafnium powder, zirconium powder and titanium dioxide powder in a ball mill and mix them uniformly in an argon protective atmosphere to obtain a mixed powder; the ball milling speed of the ball mill is 200r / min, and the ball milling speed of the ball mill is The time is 10h; the particle size of the hafnium powder and zirconium powder is not greater than 10 μm, the particle size of the titanium dioxide powder is not greater than 5 μm, and the particle size of the niobium powder is not greater than 20 μm; the hafnium powder, zirconium powder and titanium dioxide powder The mass purity is not less than 99.5%, and the mass purity of the niobium powder is not less than 99.9%;

[0038] Step 2...

Embodiment 3

[0044] In this example Nb-Hf-Zr-TiO 2 The alloy bar is made of the following raw materials in mass percentage: Hf 8%, Zr7%, TiO 2 10%, the balance is Nb.

[0045] This example prepares Nb-Hf-Zr-TiO 2 The method for alloy rods comprises the steps of:

[0046] Step 1. Place niobium powder, hafnium powder, zirconium powder and titanium dioxide powder in a ball mill, and ball mill and mix them uniformly under the protection of an argon atmosphere to obtain a mixed powder; the ball mill speed of the ball mill is 300r / min, and the ball mill The time for ball milling is 20 hours; the particle size of the hafnium powder and zirconium powder is not greater than 10 μm, the particle size of the titanium dioxide powder is not greater than 5 μm, and the particle size of the niobium powder is not greater than 20 μm; the hafnium powder, zirconium powder and titanium dioxide powder The mass purity of the niobium powder is not less than 99.5%, and the mass purity of the niobium powder is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com