Electrostatic spinning device with solid needles

An electrospinning and needle technology, applied in textiles and papermaking, filament/thread forming, fiber treatment, etc., can solve the problems of needle blockage, inconvenient cleaning, uneven field strength, etc., and achieve the goal of solving blockage, uniform field strength, Reduces the effect of electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with embodiment and accompanying drawing thereof:

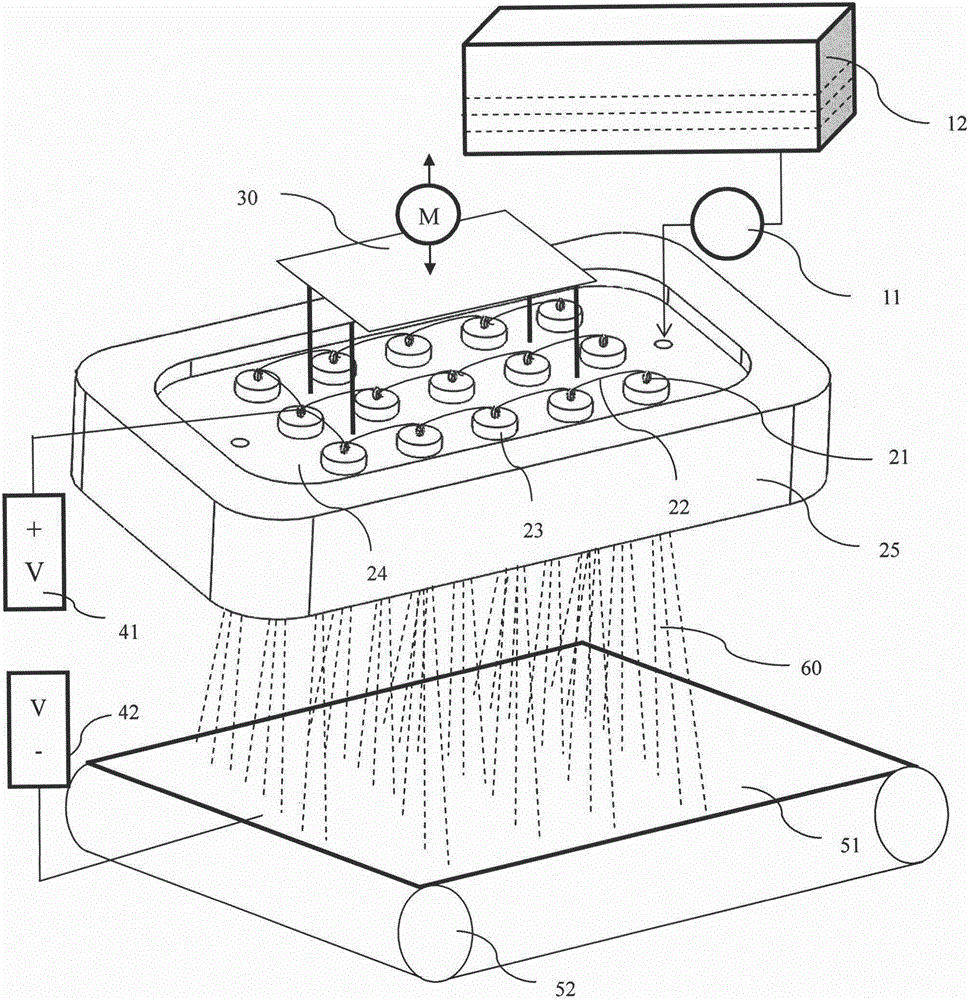

[0016] The solid needle electrospinning device designed in the present invention (referred to as the device, see Figure 1~4 ), including liquid supply system, solid needle spinning system, lifting system, power supply system, receiving device and control system.

[0017] The liquid supply system is the prior art, including a spinning metering pump (referred to as metering pump or spinning pump) 11 and a liquid reservoir 12, and the liquid inlet pipe of the metering pump 11 probes into the spinning solution in the liquid reservoir 12. Below the liquid level, under the action of the metering pump 11, the liquid supply system supplies the spinning solution quantitatively to the solid needle spinning system.

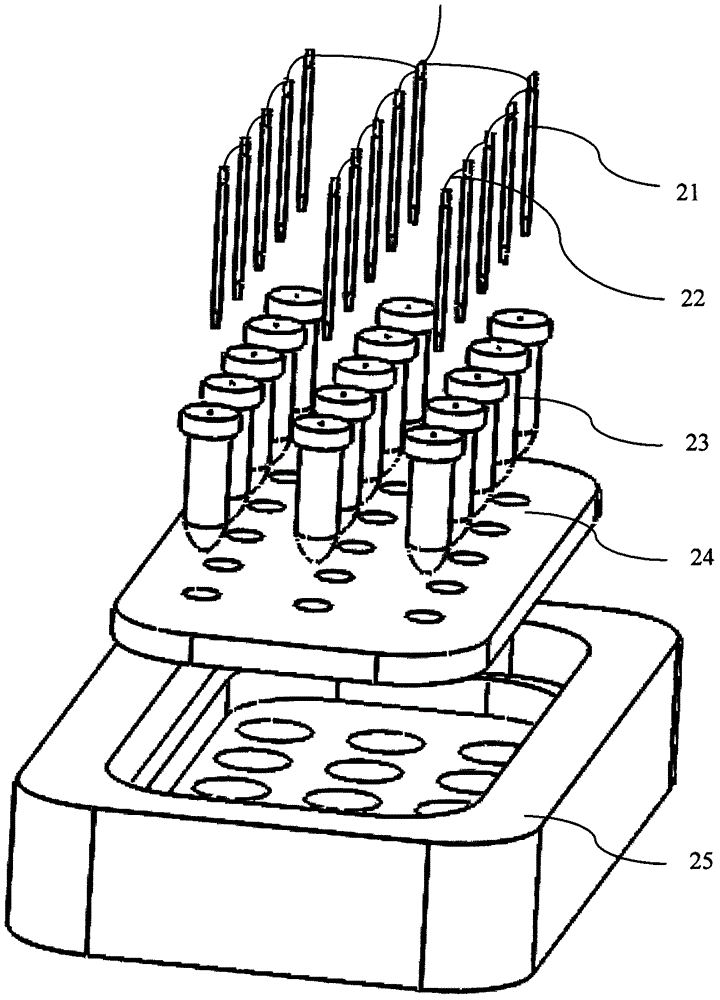

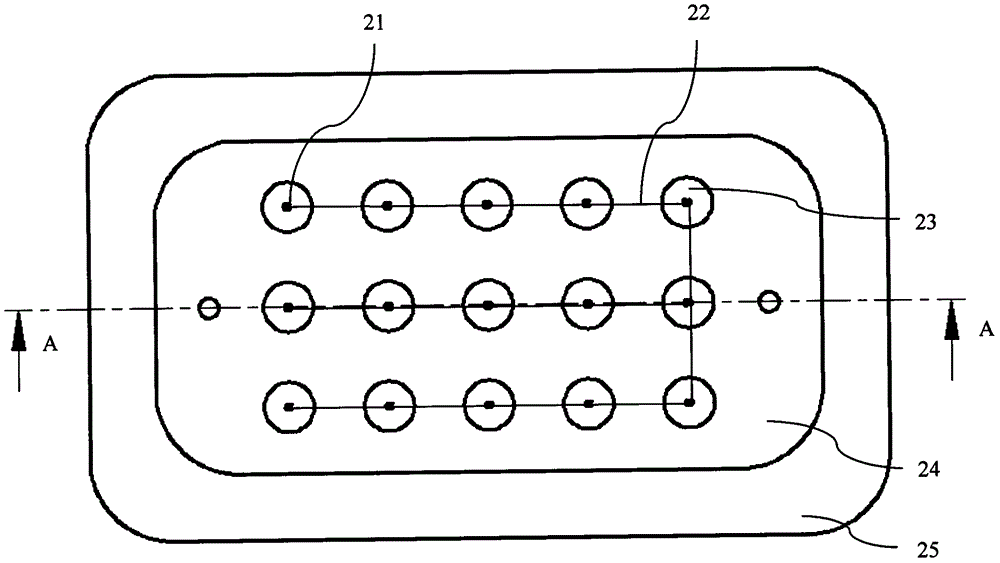

[0018] The solid needle spinning system is the core or feature of the present invention, and mainly includes a solid needle 21, a wire lead 22, an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com